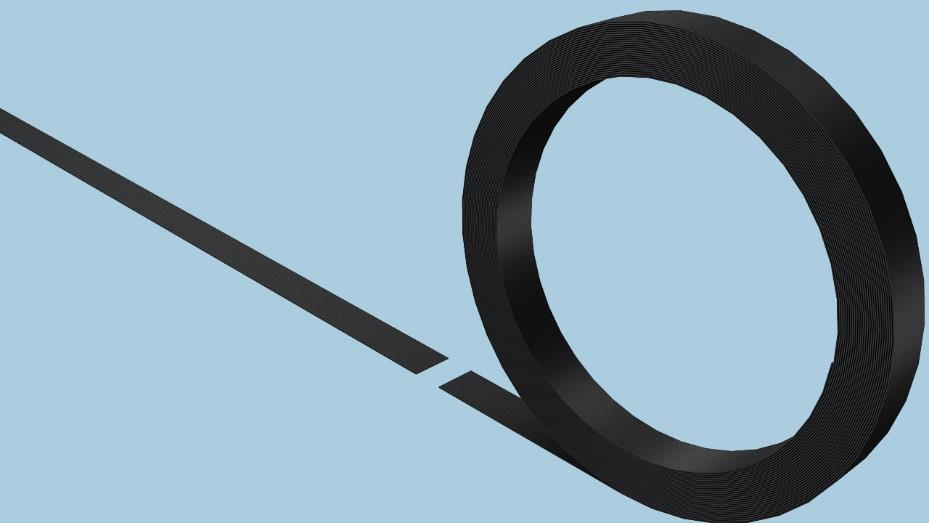

• improve the bearing capacity of bridge structure,has incomparable advantages in large-span beam slab of flexural reinforcement.

• improve the bearing capacity of bridge structure,has incomparable advantages in large-span beam slab of flexural reinforcement.

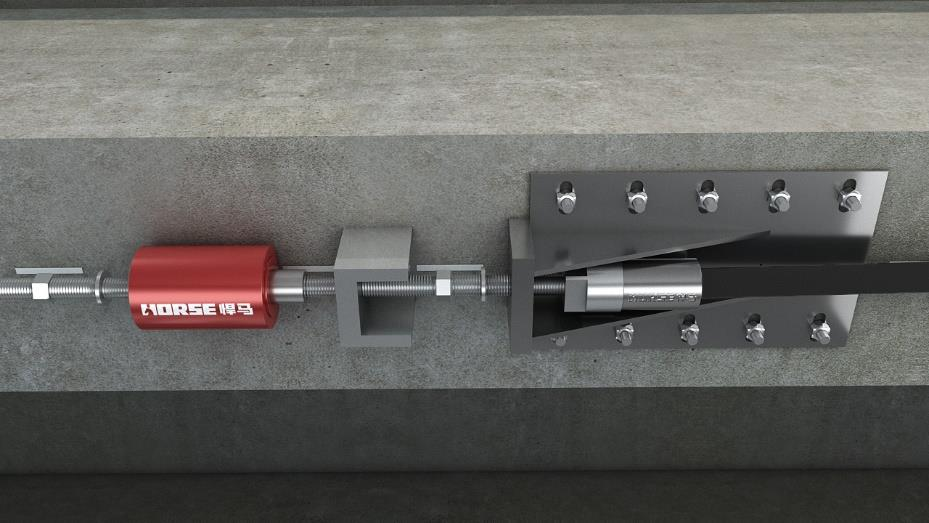

The weight of a single anchor is only 6.3kg; Reduce mass by more than half compared to square anchor blocks

The weight of a single anchor is only 6.3kg; Reduce mass by more than half compared to square anchor blocks

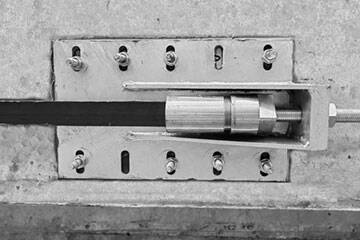

There is no need for slotting during the construction of prestressed carbon plate circular anchors, which saves construction and reduces damage to the original components

There is no need for slotting during the construction of prestressed carbon plate circular anchors, which saves construction and reduces damage to the original components

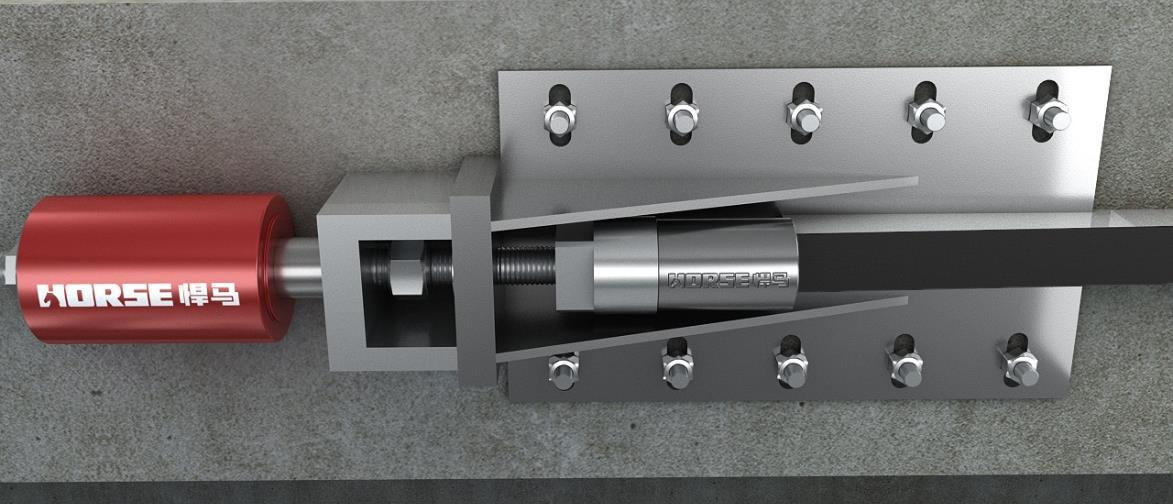

The screw passes through the limit frame to fix the circular anchor,

The screw passes through the limit frame to fix the circular anchor,

Compared with prestressed carbon plate square anchors, the stress distribution on the carbon plate in the prestressed carbon plate circular anchor is more uniform, which can effectively avoid splitting

Compared with prestressed carbon plate square anchors, the stress distribution on the carbon plate in the prestressed carbon plate circular anchor is more uniform, which can effectively avoid splitting Prestressed CFRP System Application Range

• significantly reduce deformation of the structure and improve the bearing capacity of structure,decrease the crack width and

deflection deformation,and is suitable for large span beam slab of flexural reinforcement.

• improve the stiffness of structure ,and make full use of the material performance ,save a lot of materials and engineering cost.

Prestressed CFRP System Application Range

• significantly reduce deformation of the structure and improve the bearing capacity of structure,decrease the crack width and

deflection deformation,and is suitable for large span beam slab of flexural reinforcement.

• improve the stiffness of structure ,and make full use of the material performance ,save a lot of materials and engineering cost. Small and Lightweight

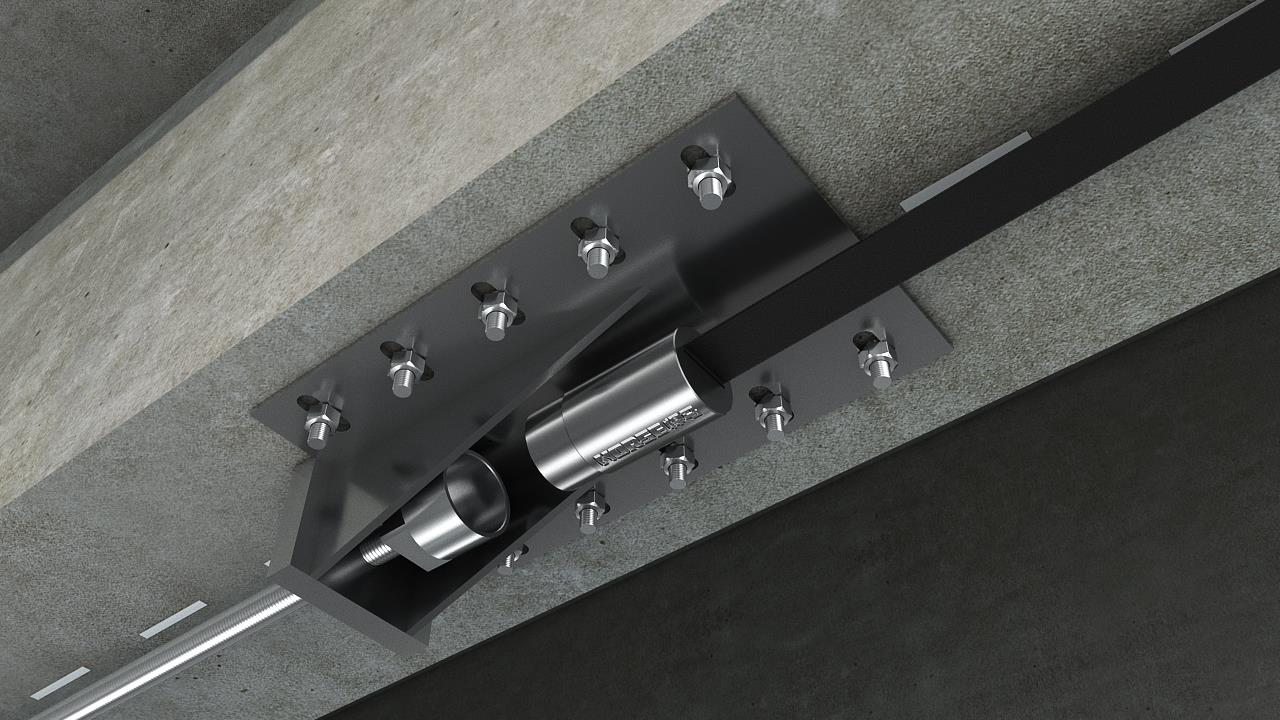

Adopting wedge-shaped self-locking clip anchor form

The greater the tension, the greater the clamping force

Optimized design of clip taper and tooth pattern

Avoiding slippage of carbon fiber laminate; Relieve stress concentration and protect carbon fiber laminate

Small and Lightweight

Adopting wedge-shaped self-locking clip anchor form

The greater the tension, the greater the clamping force

Optimized design of clip taper and tooth pattern

Avoiding slippage of carbon fiber laminate; Relieve stress concentration and protect carbon fiber laminate No Need for Slotting

No Need for Slotting

Center Tension Without Eccentricity

and the tensioning position is located at the centerline of the anchor

to avoid the bending moment generated

by the tensioning eccentricity from affecting the overall system

Avoiding eccentricity causing anchorage jamming,

resulting in excessive deviation between actual elongation and theoretical elongation

Center Tension Without Eccentricity

and the tensioning position is located at the centerline of the anchor

to avoid the bending moment generated

by the tensioning eccentricity from affecting the overall system

Avoiding eccentricity causing anchorage jamming,

resulting in excessive deviation between actual elongation and theoretical elongation

High Anchoring Efficiency

High Anchoring Efficiency

Carbon plate specifications | Anchor frame specifications | Anchor bolt (Grade 8.8) | Tensioning screw (Grade 8.8) | Fixed end screw (Grade 8.8) |

| 3.0×20 | 240×260 | M12×6 | M20×1 | M20×1 |

| 1.4×50 / 2.0×50 | 300×370 | M16×8 | M30×1 | M30×1 |

| 3.0×50 / 4.0×50 | 300×530 | M16×8 | M30×1 | M30×1 |

1. Positioning and setting out

2. Base grinding

3. Planting anchor bolts

4. Install the limit frame

5. Cutting carbon fiber plate

6. Install carbon fiber plate

7. Install tensioning device

8. Install the circular pressure strip

9. Pre tensioning

10. Apply carbon laminate adhesive

11. Formal tensioning

12. Remove the jack