• Technical data sheet:

• Technical data sheet:

• Light weight, only 1/5 of steel mesh, easier apply.

• Light weight, only 1/5 of steel mesh, easier apply.

Aviation Grade Yarn,

Aviation Grade Yarn,

Carbon fiber mesh may be used to strengthen or retrofit a wide range of concrete, steel and masonry structural elements including columns, beams, slabs, walls, pier caps, piles, etc.

Carbon fiber mesh may be used to strengthen or retrofit a wide range of concrete, steel and masonry structural elements including columns, beams, slabs, walls, pier caps, piles, etc.

• Surface preparing

• Surface preparing

Documents

HM carbon fiber mesh ↓

• Application video:

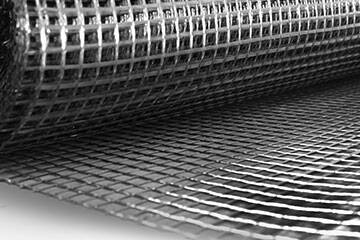

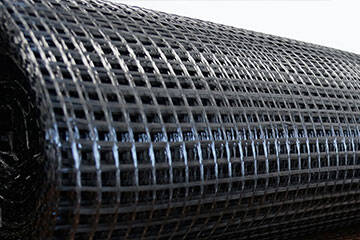

Carbon fiber mesh for structural strengthening

• Brochure:

Horse FRP strengthening system ↓

Documents

HM carbon fiber mesh ↓

• Application video:

Carbon fiber mesh for structural strengthening

• Brochure:

Horse FRP strengthening system ↓

Advantage of Carbon Fiber Mesh

• High strength, single fiber strength is 5-7 times than normal steel

• Good toughness, suitable for unsmoothly or masonry surface

• Can apply in moisture surface

• Acid, alkali & salt resistance

• Can be used for shear strengthening, confinement strengthening, flexural strengthening

• Alkali Resistant

Advantage of Carbon Fiber Mesh

• High strength, single fiber strength is 5-7 times than normal steel

• Good toughness, suitable for unsmoothly or masonry surface

• Can apply in moisture surface

• Acid, alkali & salt resistance

• Can be used for shear strengthening, confinement strengthening, flexural strengthening

• Alkali Resistant

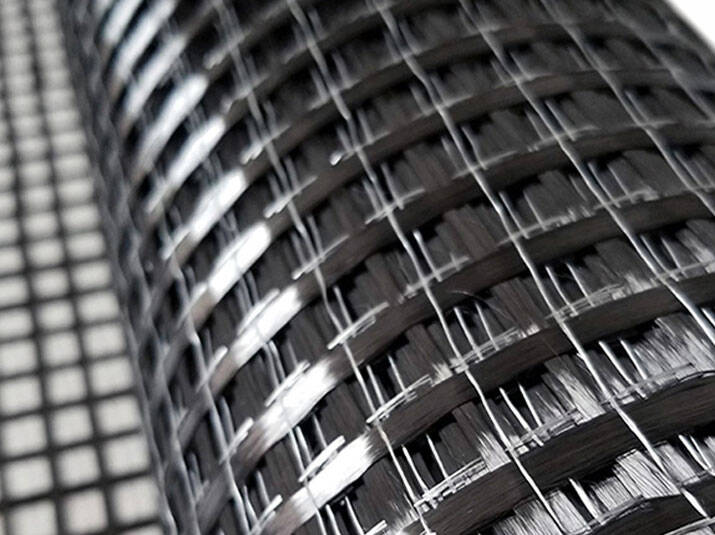

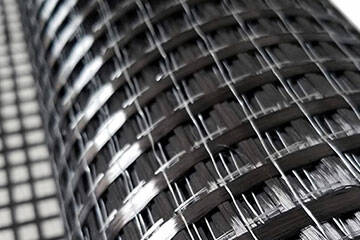

Why Horse Carbon Fiber Mesh

• Select the international high-quality aviation grade yarn, over 5000meters.

World Leading Production Line

• No damage to the yarn during the weaving process.

• Good compatiblity performance with any motar

• Various size for selects, and can be customized as per requests

Patented Tension Controling System

• Our own independent developed whole process tension controling system

Large production capacity

• 20 thousands square meters annual production capacity

• 10 thousand square meters regular daily stock

Why Horse Carbon Fiber Mesh

• Select the international high-quality aviation grade yarn, over 5000meters.

World Leading Production Line

• No damage to the yarn during the weaving process.

• Good compatiblity performance with any motar

• Various size for selects, and can be customized as per requests

Patented Tension Controling System

• Our own independent developed whole process tension controling system

Large production capacity

• 20 thousands square meters annual production capacity

• 10 thousand square meters regular daily stock

Application Range

• Strengthen for increasing load capacity.

• Address changes in structural system, like slab openings and walls, beams or columns removal.

• Retrofit for seismic, wind or blast.

• Restore strength of structural elements damaged by fire or vehicle impact.

• Restore strength to deteriorated and corroded members.

• Strengthen for design or construction defects.

Application Range

• Strengthen for increasing load capacity.

• Address changes in structural system, like slab openings and walls, beams or columns removal.

• Retrofit for seismic, wind or blast.

• Restore strength of structural elements damaged by fire or vehicle impact.

• Restore strength to deteriorated and corroded members.

• Strengthen for design or construction defects.

How to use carbon fiber mesh

• Setting out

• Blending motar

• Interface coating

• CFN fixing

• Impregnated coating

• Applying impregnation adhesive

• Maintance

• Check gap or bubble

How to use carbon fiber mesh

• Setting out

• Blending motar

• Interface coating

• CFN fixing

• Impregnated coating

• Applying impregnation adhesive

• Maintance

• Check gap or bubble

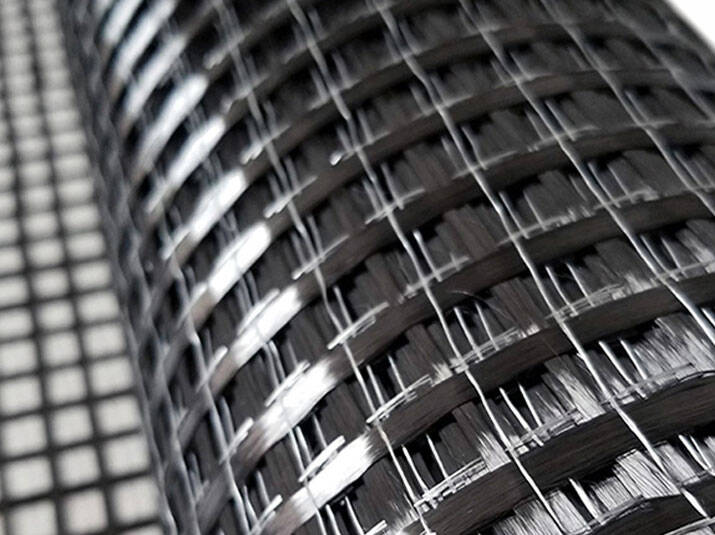

Horse Unidirectional Carbon Fiber Mesh's Data Sheet

| Basic Information | |

|---|---|

| Model | HM-CFN |

Appreance | Black fabric |

| Length | 50m |

Width | Regular width is 1000mm, other width can be customized. |

| Shelf Life | 10 years |

| Storage Conditions | Store in dry conditions at 40°F to 95°F (4°C to 35°C) |

| Braiding | 0° (Unidirectional) |

| Areal Weight | 200g/m2 |

Model | Specification | Strength Grade | Width | |

| HM-CFN100x100 | Unidirectional/Bidirectional | Mesh size 10x10 | High Strength Grade I | ≤1000mm |

| HM-CFN200x200 | Unidirectional/Bidirectional | Mesh size 20x20 | High Strength Grade I | ≤1000mm |

| HM-CFN350x350 | Bidirectional | Mesh size 35x35 | High Strength Grade I | ≤1000mm |

| HM-CFN500x500 | Bidirectional | Mesh size 50x50 | High Strength Grade I | ≤1000mm |

| Typical Fiber Properties | |

|---|---|

| Dry Fiber Typical Properities | |

| Stand Value of Tensile Strength | 4900MPa |

| Tensile Elastic Modulus | 234GPa |

| Elongation | 1.70% |

| Carbon fiber grid performance | |

| Tensile strength of the warp per unit of width | 31KN/m |

| Tensile strength of the weft per unit of width | 31KN/m |

| Elongation of the warp tow | ≥4% |

| Elongation of the weft tow | ≥4% |

| Interlaminar Shear Strength | 45MPa |

| Density | 1.82g/cm3 |

| Fiber Thickness | 0.047mm |

Application video: https://youtu.be/cjejx_0woG4

1. Surface Preparing:

Remove the coating of concrete surface with grinder. Polishing the Surface. If there is angular, grinder it into round, radius is around 25mm

2. Setting out:

After setting out, cut the HM carbon fiber grid based on request

3. Blending Motar

Blending the epoxy or polymer motar, mix it evenly.

4. Interface coating

Spraying HM motar to the surface of structurer evenly, thickness should be around 5-10mm

5. CFN fixing

Stick the carbon fiber grid into the lay out area, the gap is not allowed between the substrate and CFG

6. Impregnated coating

Coating the HM motar on the carbon fiber grid, thickness around 15mm-30mm

7.Applying Impregnation Adhesive:

Apply impregnation adhesive when primer adhesive is touch dry.

8. Maintance

After the application, the maintain time not less than 72hours

9. Check Gap or Bubble:

Check if any gap or bubble inside, if have need to repair it with additional motar.