• Technical data sheet:

• Technical data sheet:

• Good compatibility with carbon fiber.

• Good compatibility with carbon fiber.

• Reinforce the substrate concrete after chiseled.

• Reinforce the substrate concrete after chiseled.

• The carbon fiber adhesive should store in a cool and dry place,storage period is 12 months. If storage period exceed 12 months, the product should be tested, if the physical and mechanical properties meet the standard requirements,you can still continue to use it.

• The carbon fiber adhesive should store in a cool and dry place,storage period is 12 months. If storage period exceed 12 months, the product should be tested, if the physical and mechanical properties meet the standard requirements,you can still continue to use it.

• Mix proper quantity, use up in the applicable period.

• Mix proper quantity, use up in the applicable period.

Documents Download

HM-180 ↓

• Application video:

Unidirectional carbon fiber for structural strengthening

• Brochure:

Horse FRP strengthening system ↓

• Software:

Horse FRP Software ↓

Documents Download

HM-180 ↓

• Application video:

Unidirectional carbon fiber for structural strengthening

• Brochure:

Horse FRP strengthening system ↓

• Software:

Horse FRP Software ↓

Characteristics of HM-180 Primer

• Strong penetration, can well infiltrate into the concrete surface.

• Aging, water resistance and chemical corrosion resistance

• Excellent physical mechanical properties after curing, strong toughness with a certain degree of elasticity.

Characteristics of HM-180 Primer

• Strong penetration, can well infiltrate into the concrete surface.

• Aging, water resistance and chemical corrosion resistance

• Excellent physical mechanical properties after curing, strong toughness with a certain degree of elasticity.

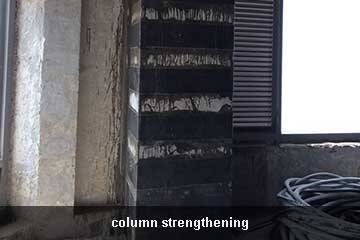

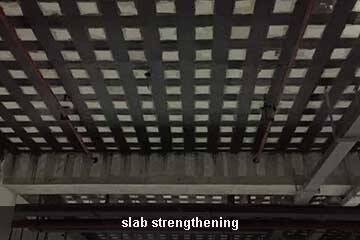

Application Range

• Used for steel, ceramic, stone, wood component and carbon fiber, glass fiber, basalt fiber, aramid fiber.

• Mainly used for the strengthening and reinforcement of buildings.

Application Range

• Used for steel, ceramic, stone, wood component and carbon fiber, glass fiber, basalt fiber, aramid fiber.

• Mainly used for the strengthening and reinforcement of buildings.

Transportation and Storage

• This product is non-toxic, belong to non-dangerous goods, transport as a goods, transport as a general chemical building materials.

Transportation and Storage

• This product is non-toxic, belong to non-dangerous goods, transport as a goods, transport as a general chemical building materials.

Attention Points

• If there is any left, the lids of A B should be covered. Do not expose it in the air.

• Construction workers should take certain protective measures.

• The construction environment should be kept ventilated during construction.

• Avoid direct sunlight and high temperature.

Attention Points

• If there is any left, the lids of A B should be covered. Do not expose it in the air.

• Construction workers should take certain protective measures.

• The construction environment should be kept ventilated during construction.

• Avoid direct sunlight and high temperature.

Horse Prime Adhesive

![]() HM CFRP Fabric Epoxy TDS - Horse.pdf

HM CFRP Fabric Epoxy TDS - Horse.pdf

| Technical Parameters | |

| Appearance | Component A: transparent viscous liquid |

| Component B: brown viscous liquid | |

| Mixture ratio | A:B=2:1 |

| Pot life (min) | >30 |

| Finger touch dry time(25℃, h) | 1~2 |

| Bonding strength | C60 concrete damage |

| Steel-steel tensile shear strength | ≥20MPa, and structural adhesive cohesion damage |

| Steel-concrete pulling bonding strength | ≥2.5MPa, and concrete cohesion damage |

| Steel - steel T impact stripping length | ≤25mm |

Horse HM-180 Carbon Fiber Primer Application Video

Carbon Fiber Strengthening Video(click it)

>>The treatment of concrete surface

The cosmetic layer, oil, dirt etc. Of concrete surface should be chiseled off and then rubbed off 1 ~2 mm thick surface layer with the

angle grinder, concrete components should be handled by chamfering on the corner, dust was blew out with compressed air after the

completion Of polishing, and finally the surface was wiped by cotton cloth dipped in acetone, and kept dry for use. If the concrete

needed to strengthen existed cracks, first choose HM-120M perfusion adhesive or HM-120L pouring crack adhesive to perfuse according

to the size of crack, and then strengthen.

>>Primer construction

When construction, two components of HM-180 primer were weighed according to the stipulated proportion of preparing glue, and

dumped into a clean container and stirred to uniformity (when mixing, best mix along the same direction to avoid the air from forming

air bubbles.) Brush or roller brush was used to evenly brush on the concrete surface, after the glue surface layer dried, it should be

brushed several times depending on the particular circumstances, but the coating thickness did not exceed 0.4 mm, and it should

not be missed out to brush, or have flowing or bubbles, waiting for glue curing (curing time was depended on the site temperature,

it was appropriate when finger felt dry, generally not less than 2 hours), then the next process was proceeded. The glue prepared

every time should be used up one time during the applicable period of the glue.

>>Leveling construction

The pores and defects on concrete surface were filled by HM-180CE leveling adhesive.When depression area was existed, the prepared leveling

adhesive was used to repair and fill through scraper embedding and scraping, the position emerging altitude difference such as the

joint of templates should be filled by leveling adhesive, which tried to minimize the height difference. The treatment of corner was that

it was repaired to smooth arc through leveling adhesive, its radius was not more than 20mm. After the leveling adhesive cured (curing

time was depended on the site temperature, it was appropriate when finger felt dry, generally not less than 2 hours), the next process

should be proceeded further.

>>Paste of carbon fiber wrap

HM-180C3P carbon fiber impregnated adhesive was smeared to the pasted area evenly,the corner site was more smeared appropriately. Paste after

hauling carbon fiber wrap tight and alignment, use a plastic scraper or roller (a paint roller that the villus was removed outside) to roll

repeatedly along the same direction, until the glue compound exuded. And then smear impregnated adhesive to the outside surface

of the carbon fiber wrap evenly, and roll repeatedly that the impregnated adhesive can immerse the carbon fiber wrap in two ways,

if it is multi-paste, until your fingers touch dry, the next layer of paste can be beginner. If the carbon fiber wrap needs overlapping

>>Curing and conservation

Prevent rain or moisture 24 hours after the completion of construction, and pay attention to protection against a hard Object bumping

into the surface of the construction. When the average air temperature is 20 , 25 ℃ , the curing time is not less than 3 days; when

the average air temperature is 10 ℃, the curing time is not less than 7 days.