Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Carbon fiber sheets retrofitting

Overview

Suzhou Wuzhong District Administrative Center Building is located in the center of Wuzhong District, Suzhou City. It was built in 1994 and is a cast-in-place reinforced concrete frame-shear wall structure. 10 floors above ground (14 floors in some parts), 1 underground floor. The total height of the building is 55.75m, the construction area is about 25000m2, and the foundation is reinforced concrete piled raft foundation.

The building has been put into use for 13 years, and it is far from meeting the current functional requirements. The owner decided to carry out a large-scale renovation in 2007. One of the main contents is the addition of central air-conditioning, which requires 52 small air-conditioning units to be placed in the at area of the roof, with a total load of about 40t (including racks). Since the original roof is not a human roof and the design live load is small, preliminary estimation shows that the bearing capacity of some beams of the roof structure layer is insufficient and must be reinforced to ensure normal use.

Beam retrofitting scheme

The process requirements of the retrofitting method and the specific conditions of the project, and comprehensive consideration of economic factors, use the elimination method to determine the final retrofitting plan.

First of all, because the building is mainly an office building, the floor height is lower than the bottom, and the original design frame beam height is 800m, so for the method of increasing the surface area, it will further reduce the space used. Moreover, the amount of wet work on the construction site was large and the construction period was long, which did not meet the actual situation of the project, so the first one was excluded.

The second is the commonly used steel-bonded retrofitting. The steel plate must be tightly attached to the surface of the concrete beam with rubber expansion bolts at regular intervals along the longitudinal direction of the steel plate. This requires a large number of holes to be drilled on the surface of the concrete beam. As the planned retrofitting construction period is in late May and early June, which coincides with the college entrance examination period, and there is a middle school nearby as the college entrance examination examination room and there are also residential areas, the noise of the drilling will inevitably have a serious impact on them. In addition, steel-bonded retrofitting has higher requirements on the working surface of the construction site. The partition wall cabinets, ceilings and pipelines in the original top-level office building must be removed in large quantities. The cost of removal and future restoration is high, and the construction period is long. Therefore, the bonding steel retrofitting method is also excluded.

Third, as for the pre-stressed retrofitting method, it is also excluded because of its high requirements for construction equipment, cumbersome on-site construction, and relatively high cost.

After full negotiation and comprehensive comparison with the design and general contractor, it was finally decided to adopt the carbon fiber sheet retrofitting method. Its main advantages are that the construction period is short. The second is that although the cost is slightly higher than that of stick steel retrofitting, the comprehensive economic benefits of the owner can still be acceptable considering the removal and future restoration of the interior of the reinforced working face.

The bearing capacity of the foundation and column can meet the requirements, but the bending and shear bearing capacity of some frame beams and secondary beams is insufficient and must be reinforced.

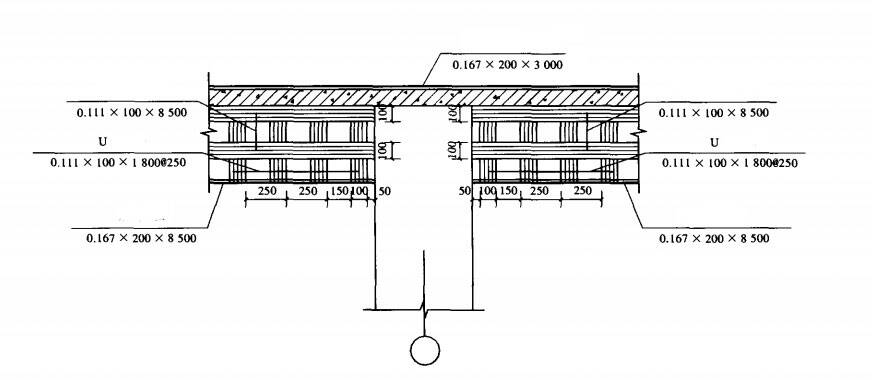

Flexural retrofitting of beams with carbon fiber sheet

Shear retrofitting of beams with carbon fiber sheet

The project started at the end of May 2007. After nearly half a month of construction, the carbon fiber sheet was pasted, which created conditions for the subsequent construction of the project in time. Now the building's renovation project has been completed and delivered to use, and no abnormal phenomenon has been found in the reinforced part.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.