Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Carbon plates have, to a certain extent, broken the traditional reinforcement concept of “the heavier, the stronger”, injecting new momentum into the structural reinforcement industry with the innovation of “strong and light”.

What are the biggest fears when reinforcing a building?

Fear of the reinforcement material being too heavy, further burdening the already aging, poorly constructed concrete structure, and suffocating it. Worry about the hassle of hoisting during construction, delaying the project. Worry about high maintenance costs, turning repairs into a protracted battle. But now, there's a better solution to these problems: carbon fiber plate reinforcement technology, redefining structural reinforcement with lightweight strength.

In a bridge reinforcement project, designers compared bonded steel and carbon fiber laminate solutions to achieve equivalent load-bearing capacity.

The bonded steel solution used Q345 steel plates with a total cross-sectional area of 16,812 mm². The plates were 11.3 meters long and weighed approximately 1,500 kg, equivalent to the weight of a small truck constantly pressing on the beam.

The carbon fiber laminate solution used only 14 5 cm wide, 3 mm thick carbon laminates and two 5 cm wide, 4 mm thick carbon laminates. The plates were also 11.3 meters long and weighed only approximately 45 kg, roughly the weight of an elementary school student.

The weight of carbon fiber laminates is only 3% of that of bonded steel, a weight reduction of over 95%! This is not a simple numbers game, but rather avoids adding a heavier burden to the already "weak" building structure.

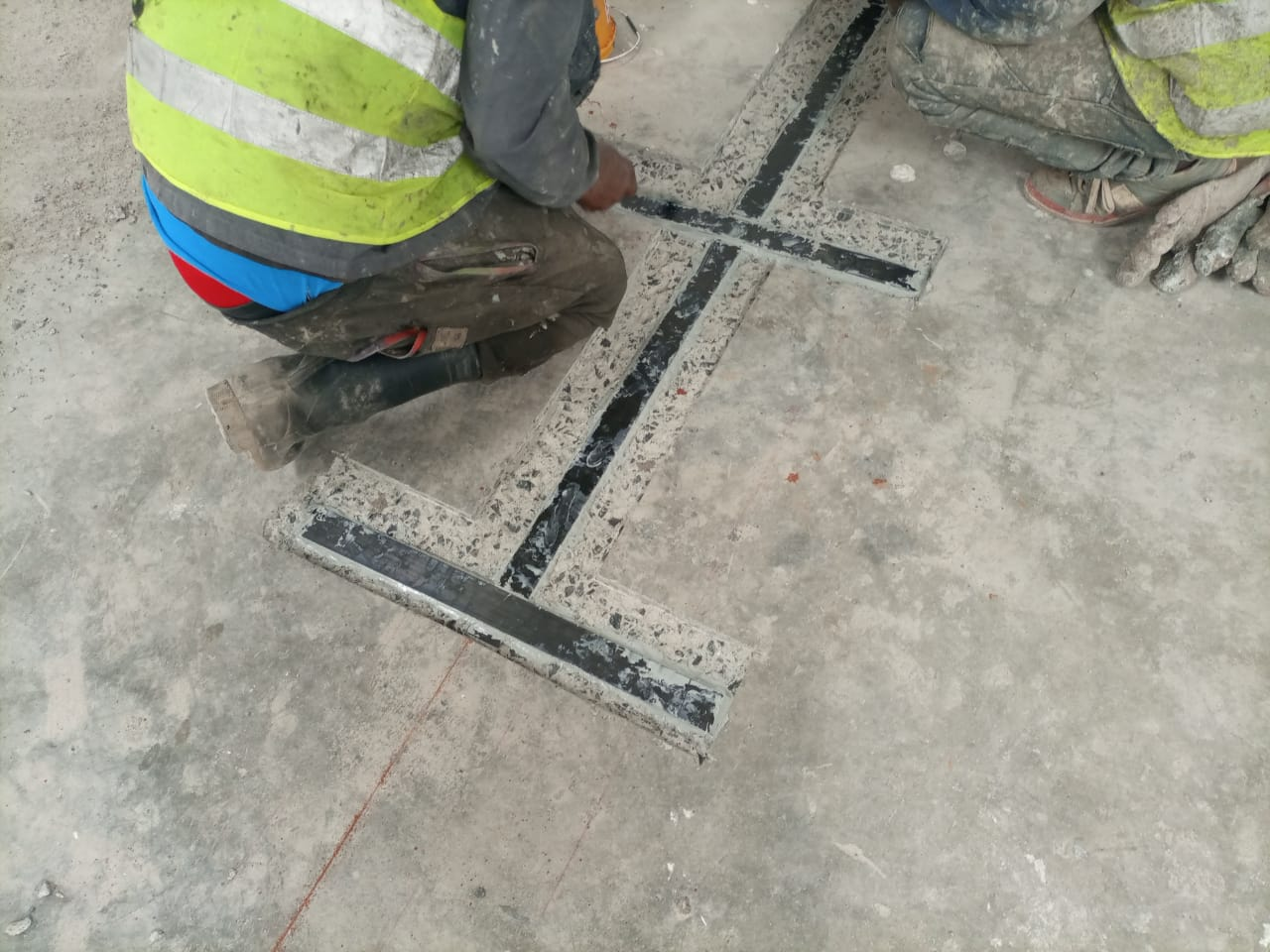

Carbon laminate is a composite material formed from carbon fiber through a pultrusion process. Leveraging the high strength and tensile strength of carbon fiber, the laminate is bonded to the surface of the original structure (concrete or steel substrate) using epoxy structural adhesive, creating a cohesive composite cross-section that shares load-bearing properties. It is primarily used to address cracks and damage in beams, slabs, columns, walls, and other structures caused by insufficient load-bearing capacity and reduced durability. It is particularly advantageous in applications with limited bonding areas and insufficient reinforcement, significantly improving the structure's bending, tensile, and seismic performance, thereby enhancing overall load-bearing capacity.

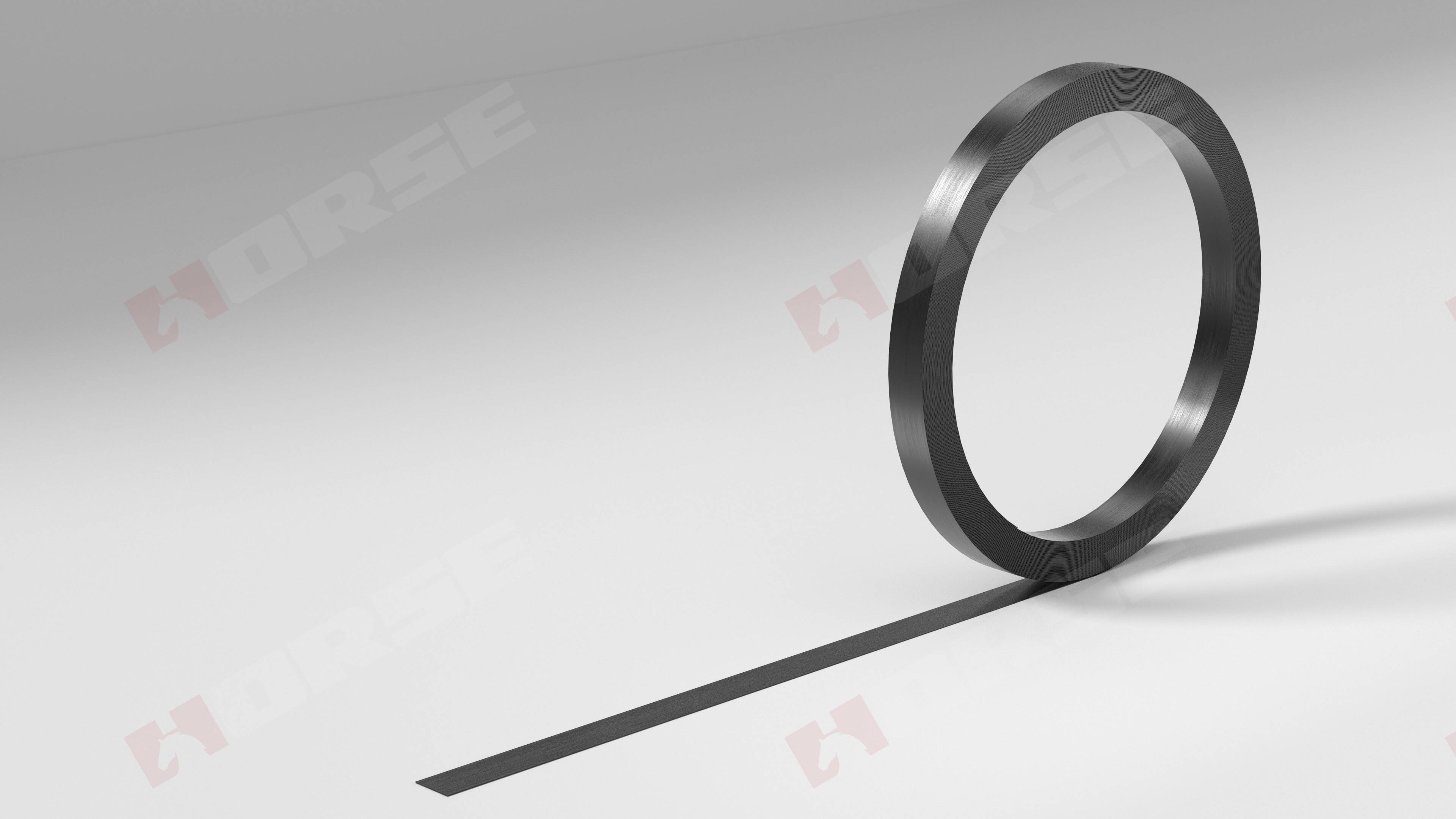

Carbon laminate is a fibrous material composed of carbon and possesses extremely high chemical stability and corrosion resistance. Carbon laminate is lightweight and has a thin reinforcement layer. A 2mm thick, 5cm wide, 1m long carbon laminate weighs only 0.15kg, placing minimal strain on the original structure. Carbon laminate has high straightness, with a deflection of less than 0.1%, ensuring linear load-bearing. The carbon laminate and carbon laminate adhesive have similar elongation rates, enabling better synergy and seamless integration between the original structure and the laminate. Over ten specifications are available to meet diverse construction needs.

Behind the "lightness" lies a tangible advantage.

The weathered original structure no longer needs to bear the weight. Weight-sensitive structures like old buildings, long-span bridges, and tall piers are most afraid of being exacerbated by reinforcement. The lightweight nature of carbon fiber laminates minimizes additional loads on the original structure, preventing new safety hazards caused by increased deadweight.

Construction Efficiency "Speeded Up"

A 1500kg steel plate requires mechanical equipment to move into the narrow site, while a 45kg carbon fiber plate can be easily carried and installed by one or two workers. Without the constraints of bulky equipment, construction time can be significantly shortened.

Not just light, but also incredibly strong.

Light doesn't mean unreliable! High-strength Grade I carbon fiber laminates boast a tensile strength exceeding 2800MPa, 7-10 times that of ordinary steel, and an elastic modulus ≥160GPa. Combined with specialized carbon fiber adhesive, they form a seamless integration with the original structure for enhanced load-bearing performance.

Effortless and hassle-free post-maintenance.

Steel is susceptible to corrosion and requires rust-proofing treatment. Carbon fiber laminates, on the other hand, are extremely chemically stable and are resistant to acidic, alkaline, and humid environments. They require virtually no additional maintenance and are particularly suitable for specialized environments such as bridges and chemical plants in coastal areas, reducing operational costs.

Carbon plates have, to a certain extent, broken the traditional reinforcement concept of “the heavier, the stronger”, injecting new momentum into the structural reinforcement industry with the innovation of “strong and light”.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

High strength carbon fiber reinforced polymer plate adhesive for applying CFRP laminate/strip/plate on the structural members

High strength carbon fiber reinforced polymer(CFRP) plate for structural strengthening and concrete repair