Chimneys & Smoke Stacks Repair

Carbon Fiber Reinforced Polymer(CFRP)

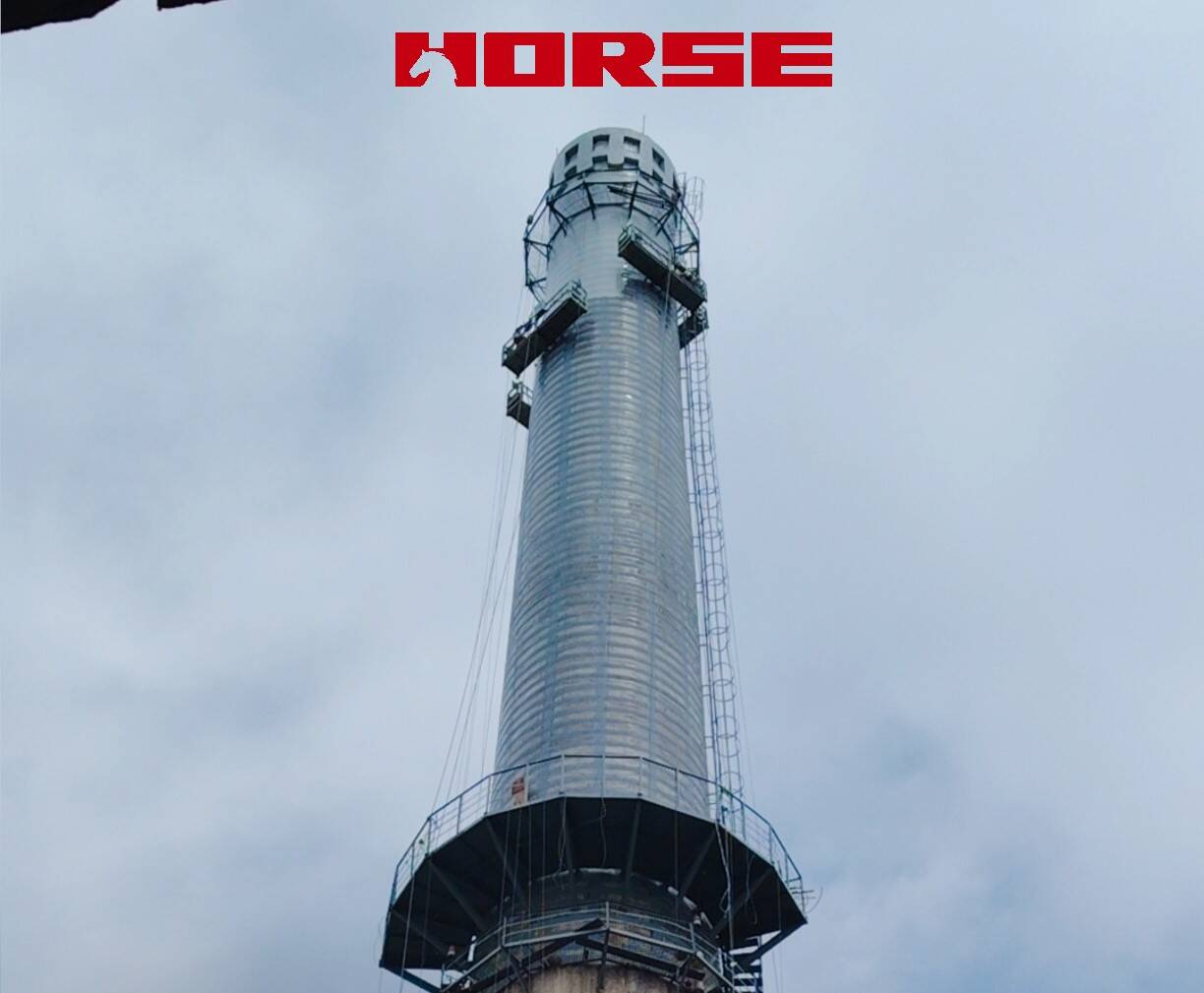

A reinforced concrete chimney, 80 meters high and built in the 1980s, was found to have multiple vertical cracks and surface concrete carbonization and spalling during a recent plant-wide equipment safety inspection.

A reinforced concrete chimney, 80 meters high and built in the 1980s, was found to have multiple vertical cracks and surface concrete carbonization and spalling during a recent plant-wide equipment safety inspection.

Structural engineers assessed that the chimney's load-bearing capacity and seismic performance no longer meet current national standards and urgently require reinforcement.

Challenges of Traditional Solutions

Initially, the engineering team considered two traditional reinforcement options:

**Increased Cross-Section Method:**

Rebar was re-tied around the existing chimney, formwork was erected, and concrete was poured. This method would significantly increase the chimney's cross-section and weight, potentially requiring additional foundation reinforcement. The construction period was long (estimated to be over 60 days), requiring extensive scaffolding at heights, resulting in very high costs for materials, labor, and time.

**Steel Wrapping Method:**

Steel plates were wrapped around the chimney and structural adhesive was injected. While this method improved strength, the steel plates were heavy, making transportation and hoisting difficult, welding complex, and posing long-term maintenance challenges related to rust and corrosion prevention.

Both options were rejected by the client due to their excessively long construction periods, high costs, and severe disruption to normal factory production.

Innovative Solution: Carbon Fiber Material Reinforcement

Following technical evaluation, the project team ultimately decided to use advanced carbon fiber composite materials for reinforcement. This solution perfectly met the client's core requirements for rapid construction, cost savings, and no disruption to production.

Significant Time Savings:

The entire reinforcement construction process took only 15 days, saving over 75% of the time compared to traditional methods (over 60 days). This is mainly due to the lightweight nature of CFRP materials, their availability in rolls, and the elimination of the need for heavy machinery and complex welding on-site.

Huge Material and Cost Savings:

Material Savings: CFRP materials have high strength and require less material. This project avoided the use of hundreds of tons of concrete and steel.

Reduced Overall Costs: Due to the significantly shortened construction period, labor costs, equipment rental fees, and management costs were correspondingly reduced. More importantly, the factory downtime for maintenance was minimized, saving the owner significant production losses. The total project cost was reduced by approximately 40% compared to traditional methods.

Superior Structural Performance Improvements:

High Strength: As stated in the information, the reinforcement layer reached its design strength within 24 hours, ultimately increasing the overall bending and shear strength of the chimney by over 50%, fully meeting and even exceeding safety specifications.

No increase in self-weight: CFRP material is extremely lightweight, and the increase in the weight of the chimney and foundation load after reinforcement is negligible, requiring no additional foundation treatment.

Excellent durability: Carbon fiber has extremely strong fatigue resistance and corrosion resistance, greatly extending the service life of the chimney and reducing future maintenance costs.

Minimal construction disruption: The construction process involves low noise, no wet work, and minimal construction waste, minimizing the impact on the normal operation of other areas of the factory.

CFRP's "short, quick, and efficient" advantages in chimney reinforcement—it solves the safety hazards of old chimneys and completes construction in a shorter period and at a lower cost, meeting the "uninterrupted production/minimum production stoppage" operation and maintenance needs of industrial facilities.