RC Cantilever Member Reinforced

Carbon Fiber

Carbon Fiber Reinforced RC Cantilever Member

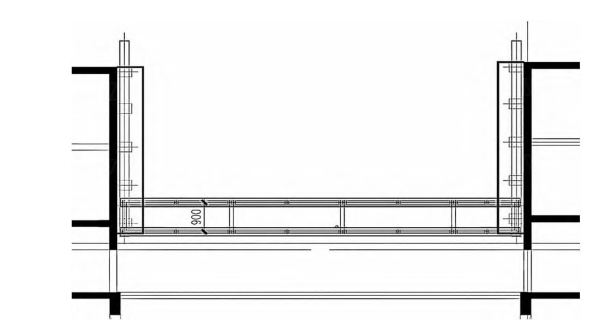

The partial cantilever length of the 7# building roof structure is 3800mm% 5600mm, and the structure with the largest span is 11000mm. During the design of the construction formwork scheme for the large-span cantilevered structure of the roof, the relevant personnel fully considered the practical difficulties such as the technical difficulty of high-altitude operation, and adopted the elevated formwork construction scheme for special parts to reduce the construction cost and shorten the construction period.

Carbon Fiber Strengthening Reinforced Concrete Cantilever Member

1) During the carbon fiber reinforcement period, a flat shovel should be used first to remove the plastering layer of the reinforcement part of the beam, so that the concrete beam body is exposed. The bonding surface is properly ground with an angle grinder to remove the surface structure with a thickness of 2 ~ 3mm, so that the new concrete surface is exposed. The sticking area of the corner of the bottom of the beam needs to be chamfered and polished to form a rounded corner with a diameter of 20mm. Use wire brushes or sandpaper to remove oil and scum on the concrete surface, and use acetone to clean it to make the concrete surface stick to the carbon fiber;

2) Before pasting the carbon fiber cloth, the construction personnel need to cut it according to the design size, and the control error is within 20mm. During the pasting period, the primer is limitedly applied, the bonding materials are placed inside the container, and the materials of group A and group B are mixed, and the electric mixer is used to continuously stir. After the colored streaks have completely disappeared, pour the mixture into the clean container and stir at low speed for 1 min. After the mixing is completed, use a roller brush to apply the binder to the pre-treated concrete surface to ensure that the binder is completely infiltrated into the concrete pores, and no problems such as flow, air bubbles, and missing coating may occur.

3) The surface of the concrete structure adopts

Filling with leveling glue, if the height difference of the formwork joints, needs to be filled with leveling glue, and the corner area should also be repaired with leveling glue to prevent problems such as stress concentration of the carbon fiber material in the corner area. After the leveling glue is cured, the construction personnel use a roller brush to evenly apply the adhesive to the surface structure of the substrate, and properly bond the carbon fiber cloth. After the operation, a plastic roller is used to repeatedly roll the carbon fiber cloth to remove internal air bubbles to ensure the bonding effect. After the first layer of carbon fiber cloth bonding is completed, the construction personnel need to use the same scheme to complete the second carbon fiber cloth bonding, and pay attention to surface protection after construction to ensure the construction effect.