Reinforce Concrete Structure Crane Beam of Hydropower Plant

Carbon Fiber Sheet

By taking advantage of the strong mechanical properties of carbon fiber material itself, and supporting the use of adhesives, it can enhance the bond strength with the base material and greatly improve the tensile strength of the carbon fiber cloth. The carbon fiber wire can work well with the reinforced concrete structure to achieve the purpose of strengthening the crane beam.

This industrial plant has a single-story ground layout with a reinforced concrete frame structure. The original plant was designed and installed two single-horizontal water turbine generator sets. Due to the large peak power consumption, the equipment in the plant has been expanded, and 3 generator sets have been added successively, and 5 generator sets in the existing power station are maintained within the original design allowable load range.

Due to the long-term operation of the hydroelectric power station, some hydraulic structures were damaged, maintenance was very inconvenient, the overall coordinated operation was not smooth, most of the equipment was outdated and aging, and the technology was backward, which has seriously affected the safety and use of the power station.

According to the design requirements for the replacement of electrical equipment, a 7.5t manual bridge crane in the existing plant needs to be replaced with a 10t electric bridge crane. After the equipment is upgraded, the weight of the unit has increased by 33%. The self-weight of the new bridge crane is also higher than that of the old bridge crane. The reinforcement construction task of the crane beam must be completed before the installation of the old plant unit, and the existing installation construction must not be affected.

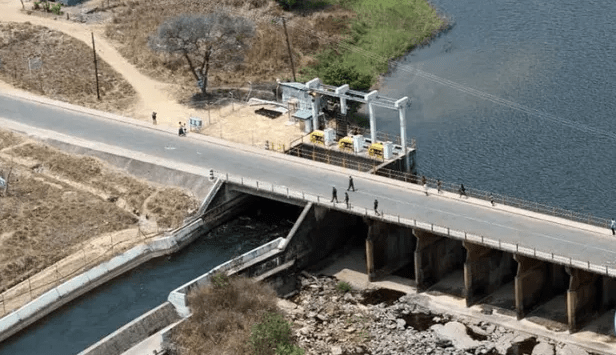

The old main powerhouse of the Musongda Hydropower Station is 47.85m long, and the upstream and downstream widths are 7.6m. The working space is relatively narrow. If the traditional construction method is used to rebuild and strengthen the crane beam, its construction technology is severely restricted. For the reinforcement and transformation, it is proposed to increase the section of the crane beam, increase the support, and strengthen the steel plate, which will affect the installation of the next unit, and the increase of the section of the crane beam and the increase of the support plan are limited by the narrow space, and the construction equipment cannot be constructed. The plan of reinforcement with steel plates also requires support, and the construction period is long, and it is also restricted by the narrow space and affects the subsequent installation of the unit.

After comparing various plans, Zambia decided to adopt the "carbon fiber cloth reinforced concrete structure technology". By taking advantage of the strong mechanical properties of carbon fiber material itself, and supporting the use of adhesives, it can enhance the bond strength with the base material and greatly improve the tensile strength of the carbon fiber cloth. The carbon fiber wire can work well with the reinforced concrete structure to achieve the purpose of strengthening the crane beam.

In the reconstruction project of the Musonda Hydropower Station in Zambia, the technical scheme comparison and practical application of the construction of crane beams in the industrial plant reinforced by carbon fiber cloth have improved the construction process, which is conducive to the installation and construction of industrial equipment. The application market for new materials and new technologies has been broadened, and good social and economic benefits have been achieved.