Bridge Strengthening

Strengthening Concrete Structures with Carbon Fiber Sheet

Main bridge reinforcement materials and engineering quantities (1) HM carbon fiber plate: 1.4mm thick and 10cm wide. The dosage is 769.6m. (2) HM-30 carbon fiber cloth: 300gsm, 0.167mm thick. The dosage is 444m.

1 Bridge Overview

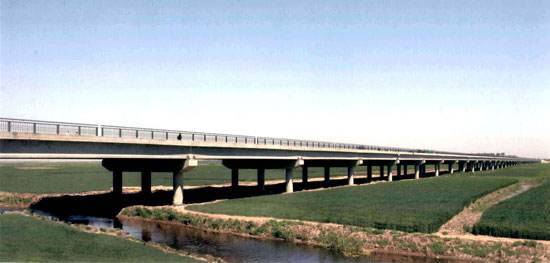

The Baiyangdian Bridge is located on the south side of Anxin County. The route is a third-class highway, with a roadbed width of 9m and a pavement width of 7m. The superstructure is a simple supported beam bridge with I-beams, few reinforcements and micro-bent plates, with 5 horizontal beams with a spacing of 1.6m and a beam height of 80cm. The end of the arched micro-bending plate is 20cm thick, the middle is 10am thick, and the net span is 1.3m. The lower structure is a double-pillar pier and a bored pile foundation. The column diameter is 0.8m, the pile diameter is 1.0m, the column spacing is 4.2m, the total length of the bridge is 1184m, and the bridge deck width is: net 7m+2×1.0m sidewalk. The current level of the bridge is three types of bridges.

2 Bridge disease status

(1) Vertical cracks appear in the middle of individual main beams of I-beams, and the width of the cracks is 0.1 to 0.15 mm. Oblique cracks appeared at the ends of very few main beams with a width of 0.1 mm. No cracks were found in the middle span and ends of the remaining main beams.

(2) Part of the pier column concrete is weathered and spalled, concrete is chipped, and steel bars are exposed and corroded. The pile foundation is exposed in the water, and the necking phenomenon appears.

3 Main bridge reinforcement materials and engineering quantities

(1) HM carbon fiber plate: 1.4mm thick and 10cm wide. The dosage is 769.6m.

(2) HM-30 carbon fiber cloth: 300gsm, 0.167mm thick. The dosage is 444m.

4 Carbon fiber construction plan

(1) Set up scaffolding;

(2) Surface crack treatment of components;

(3) The surface layer of the component is polished;

(4) Apply primer;

(5) Use epoxy putty to repair defects on the surface of the component;

(6) Cut carbon fiber (plate) cloth according to requirements and dosage;

(7) Brush dipping glue and stick carbon fiber (plate) cloth;

(8) Surface protection.

5 Conclusion

This project only took less than two months from design to completion and commissioning. The construction was reinforced with carbon fiber sheets and carbon fiber plates. It only took 15 days from preparation to completion without any quality problems. The construction effect was good.