Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

The use of unidirectional carbon fiber sheet and carbon plate reinforcement in a complex building

Reconstruction project of extraction workshop in comprehensive building of Guangdong Pharmaceutical Co., Ltd. Due to production needs, the original structure needs to be reinforced with unidirectional carbon fiber sheets and carbon plates to meet the requirements. The advantages of this technology: light weight, high tensile strength, strong corrosion resistance, high temperature resistance, convenient construction, etc.

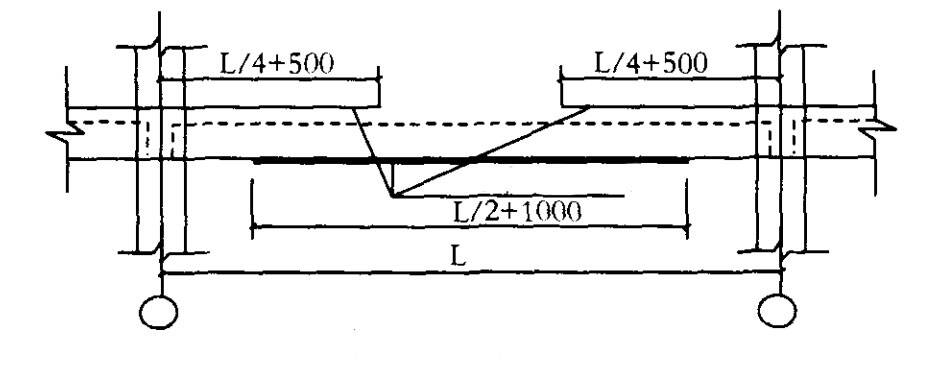

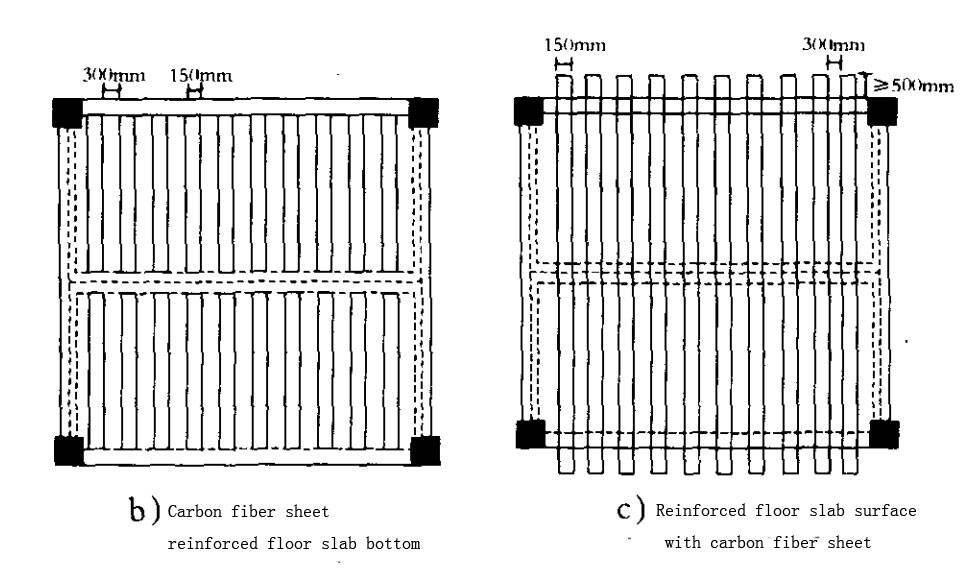

The scheme design is issued by the Design Institute with a structural reinforcement plan. The reinforcement plan is shown:

Strengthening materials

The materials for the reinforcement project are made of carbon fiber plate, carbon fiber sheet and matching HM epoxy adhesive, primer, and impregnating resin produced by Horse.

Construction process

Positioning, line-up, surface pretreatment, adhesive preparation, glue application, carbon fiber bonding, curing, test.

When pasting the carbon fiber plate, first use a spatula to apply a thin layer of the prepared adhesive on the concrete part to be pasted and the plate, and note that the board and concrete surface should maintain a minimum paste thickness of 2mm. Then lightly compress the carbon fiber plate on the concrete surface by hand. And use a rubber roller to roll evenly and smoothly along the fiber direction, and the force should be appropriate to make the adhesive overflow from both sides of the plate. Use a spatula to scrape off the overflowing adhesive to ensure that the adhesive surface is dense and without voids.

When sticking the carbon fiber cloth, evenly smear a layer of the prepared impregnating resin on the primer surface with a thickness of 1-2rm. Then stick the carbon fiber cloth on the concrete surface coated with impregnated resin. Press it in place with a roller, apply another layer of impregnating resin with a brush, and use the roller to roll along the carbon fiber direction several times to squeeze out bubbles and make the impregnated resin fully penetrate the carbon fiber cloth. When pasting multiple layers of carbon fiber cloth, in addition to repeating the above steps, the next layer should be pasted when the impregnating resin on the surface of the carbon fiber cloth is not cured, and the impregnating resin should be evenly spread on the surface of the last layer of carbon fiber cloth.

Construction operation points and matters needing attention

1) The load on the reinforced part needs to be removed. This can ensure that the structure is in a safe state during the reinforcement construction, reduce and eliminate the stress and strain hysteresis of the carbon fiber, and give full play to the reinforcement effect.

2) The base surface to be reinforced must be clean, solid, smooth and dry.

3) The bending of the carbon fiber sheet should be avoided during the construction process.

4) When sticking carbon fiber materials, attention should be paid to completing the pasting work before the curing of the adhesive to ensure that the adhesive can be closely adhered to the concrete surface and the carbon fiber material. In this way, the maximum stress transfer between the reinforced structure and the carbon fiber sheet can be achieved.

5) When rolling the carbon fiber cloth, the pressure of the blanket cylinder should be even. It can be rolled in one direction, or rolled in two directions from the middle. But it is not allowed to roll back and forth repeatedly, so as not to damage the carbon fiber and affect its quality.

6) When the adhesive is cured at room temperature, it is strictly forbidden to move the pasted carbon fiber board within 24 hours, and avoid rain, wind, sand and dust pollution.

The effect of project reinforcement

After random inspection tests on the construction site, the inspection results meet the design requirements, and the reinforcement performance and quality of the unidirectional carbon fiber sheets and carbon fiber boards can be guaranteed to achieve the expected results and produce better comprehensive benefits. Since the plant was put into use in 2006, it has been used for many years. The current conditions of use are all normal and the effect is good.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.