Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

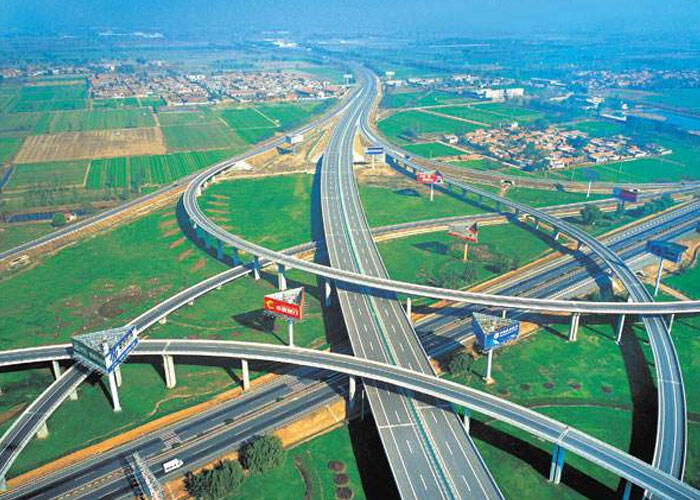

The use of carbon fiber in strengthening the bridge of Jiqing expressway

Project overview

The Jinan-Qingdao Expressway was opened to traffic since the end of 1993. With the increasing number of heavy vehicles, structural cracks appeared in the beams and slabs under the repeated action of heavy vehicles, which seriously affected the safety of the structure and needed repair and reinforcement to meet the needs of increased traffic . From 2005 to 2008, 67 beams and slabs of the Qingdao section of the Jinan-Qingdao Expressway were reinforced with unidirectional carbon fiber fabric. From the results of use and testing, the effect was good.

Process principle of carbon fiber reinforcement

Carbon fiber cloth is made of unidirectional arrangement of carbon fiber filaments with extremely high tensile strength and woven by a special process. When in use, carbon fiber cloth is glued to the reinforcement part of the concrete structure with a cementing material along the force direction or perpendicular to the crack direction. The cementing material serves as the shear force between them, which increases the tensile or shear resistance of the structure. And can effectively improve the strength, ductility and crack resistance of the structure, and control the continuous development of cracks and deflection. If necessary, unidirectional carbon fiber sheets can also be cross-bonded. The key of the whole process lies in the adhesion and tightness and firmness of the carbon fiber cloth to ensure that it is integrated with the original structure. The bonding material is a special matching epoxy resin.

Carbon fiber reinforced material

1 The materials used for carbon fiber cloth repair and reinforcement of concrete structures can be divided into two categories: carbon fiber cloth and special epoxy resin matched with it. The matching resin is divided into primer resin, leveling resin and paste resin. The supporting resin is prepared by the main agent and curing agent; it is divided into winter type and summer type suitable for use in winter and summer. The main agent and curing agent are packaged separately. When acting on site, they should be mixed evenly according to the process requirements and in the specified ratio to form the required primer resin, leveling resin, and bonding resin.

2 Carbon fiber cloth has the following characteristics: (1) High elastic modulus to provide effective reinforcement; (2) High strength; (3) Small change in strength between individual fibers; (4) The strength is stable and remains unchanged during manufacturing and handling.

3 Characteristics of bonding material

The performance of the bonding material is the key to ensuring the cooperation between carbon fiber and concrete, and it is also the weak link in the way of transmitting force between carbon fiber and concrete. It should have sufficient rigidity and strength to ensure the transmission of shear force between carbon fiber and concrete, and at the same time apply sufficient toughness to prevent brittle bond failure due to concrete cracking. In addition, it should be adapted to the on-site construction conditions, that is, it can be cured under normal conditions, has suitable fluidity and viscosity, and has low curing shrinkage. Adhesive materials mainly include three types: primer, leveling material and impregnating resin. Its properties are as follows:

1) primer

It is immersed in the concrete surface to strengthen the surface strength of the concrete so that the adhesion between the concrete and the carbon fiber cloth is improved.

2) leveling material

Carbon fiber cloth is likely to be damaged or hollow due to sharp protrusions, dislocations, and corners on the surface of the concrete, resulting in reduced strength. The leveling material can fill up the voids or slopes caused by the deterioration of the concrete surface or the surface treatment. On the other hand, it can be used for 90%. After the corner is polished, it is made into an arc shape.

3) impregnating resin

Combine the continuously pasted carbon fiber cloth together to make it harden in a plate shape, so that the fibers are combined with each other, uniformly resist external forces, and exert the overall strength of the fiber. At the same time, the carbon fiber cloth and concrete are bonded together to form a composite whole to resist external forces together.

Suggest of carbon fiber strutural strengthening

The sticking carbon fiber reinforcement method has simple construction technology and ideal reinforcement effect, but it must be done at the right time and coordinated with other reinforcement methods. For the cracks that appear at the bottom of the board, the appropriate reinforcement method should be selected after the cause of the cracks has been identified. The disease should be as early as possible, and the disease is relatively single, and there are no other diseases (such as efflorescence, alkali corrosion, hinge water seepage, etc.) at the bottom of the board. In the case where there are multiple diseases at the bottom of the slab, and cracks are the main cause, it is recommended to solve the waterproofing of bridge deck paving. In the case of ensuring good waterproof and drainage effects, the process of pasting and reinforcement is adopted to avoid alkali corrosion affecting the effect of pasting and reinforcement. At the same time, after pasting and strengthening, the height limit signs should be set according to the specific conditions of the reinforced bridge to ensure that the reinforcement materials are not damaged by external factors.

Benefit analysis

The test results of the veneer before and after reinforcement and the dynamic and static load test results of the entire bridge after reinforcement show that the reinforcement effect is good. Practice shows that the direct benefits of carbon fiber reinforcement are short construction period, quick results, no impact on normal traffic, and less human resources. Compared with the traditional replacement beams, the cost of carbon fiber cloth is relatively high, but the scope of application of the two is different. Carbon fiber cloth reinforcement method is suitable for bridge slab reinforcement where the construction period is tight, traffic should not be interrupted, and the crack damage is not serious. However, it is recommended to replace the beam slab if the slab body is seriously damaged. This method has a relatively long construction period, and traffic must be interrupted during construction, which will cause inconvenience to passing vehicles and pedestrians and require more manpower and material resources.

Concluding remarks

my country's highway construction has gradually entered the maintenance and reconstruction stage, and a large number of bridge structures need to be reinforced to meet the needs of increased traffic. Carbon fiber has excellent mechanical properties and is an ideal bridge reinforcement material. Fortunately, the quality of domestic carbon fiber is close to that of developed countries such as Japan and the United States, and the price is also rapidly falling. It can be concluded that carbon fiber will play a huge role in the future bridge reinforcement.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.