Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

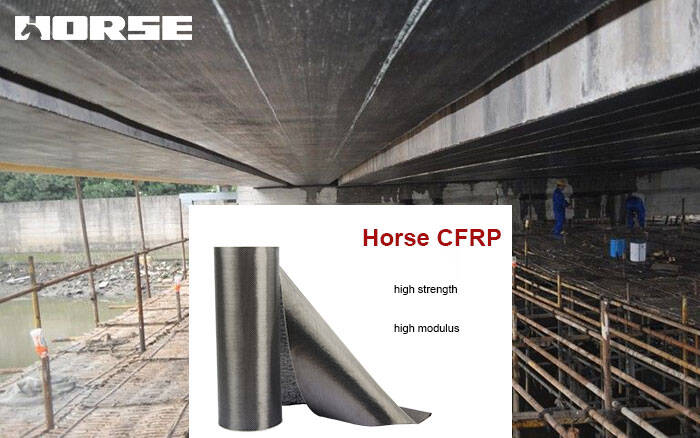

strengthen the T-beam with carbon fiber reinforced polymer

Project Overview

A bridge project was built in 1971. The overall length of the bridge is about 239.15 m, the width is 12.1 m, a total of 16 holes, and the diameter is about 13.9 m. The upper structure of the bridge project is T-shaped beams, and the lower structure is piled abutments. Due to the long construction time of the bridge and the long-term vehicle load, the bridge has suffered from various degrees of disease. At the same time, the width of the bridge can not meet the increasing demand for vehicle travel, and the bridge needs to be widened and strengthened. After a comprehensive analysis, it was finally decided to strengthen the T-beam with carbon fiber reinforced polymer. After the test, the reinforcement effect was better.

Construction plan of carbon fiber reinforcement

Bending and Strengthening Plan for the Main Girder of T-beam of Bridge

18 × 1 800 (cm) and 18 × 400 (cm) carbon fiber sheets were used to press the bending moment under the mid-span of the main beam. A 12cm wide U-shaped hoop is placed at each end of each layer to fix the carbon fiber sheet.

Scheme of Shear Strengthening of Main Girder of T-beam of Bridge

The reinforcement position is determined to be close to the fulcrum diaphragm, and a U-shaped outer hoop with a width of approximately 20 cm is added, and a main beam is set to 12 channels. For the position of the web at the end of each main beam, use a U-shaped lateral outer envelope with a width of about 20 cm.

Carbon fiber reinforced and reinforced construction process

In the widening and strengthening treatment of the bridge project, strictly follow the carbon fiber reinforcement and reinforcement process: treat the surface of the beam member cleanly → further clean the substrate → paint the mixed paint on the bottom layer → scrape the substrate flat→ Carefully paint a layer of impregnated resin → Paste the fiber sheet at the position where reinforcement is needed → Apply another layer of impregnated resin → Do the subsequent maintenance and repair work → Paint the protective material.

Comparative analysis of carbon fiber reinforcement

After the bridge was strengthened, it was found after testing that the dynamic and static load data of the bridge were significantly improved, and played an extremely effective role in strengthening. It can be seen from this case that the carbon fiber reinforcement technology is simple to operate, does not require large equipment machinery, only needs to use small electric tools, and the number of operators is small. The construction efficiency is high, the cost is low, and there is no need to interrupt the traffic. The impact on the construction environment is relatively small, which can significantly shorten the construction period, and the social and economic benefits are very significant. At the same time, the construction technology can significantly increase the service life of the building, and the reinforcement cost is low.Compared with reinforced concrete reinforcement, the cost of carbon fiber reinforcement may be slightly higher, but the overall construction period is shorter and the total cost is still lower. Therefore, carbon fiber reinforcement is very suitable in bridge projects where the body of the bridge is slightly damaged, the construction period is high, the traffic flow is large, and it is not suitable for traffic interruption. At the same time, it is also very friendly to the repair of bridge cracks. If the bridge engineering structure is severely damaged and a large area of concrete fragmentation occurs, the reinforcement method of reinforced concrete reinforcement should be used. This method has a long construction period and requires traffic interruption.

Conclusion

Most of the bridges in my country were built in the 20th century. With the increase of service life, most bridges began to show different degrees of disease and need to be dealt with urgently. Among them, carbon fiber reinforcement technology is widely used in bridge reinforcement engineering. Its construction operation is convenient, the construction period is short, and the reinforcement effect is excellent. Therefore, in the reinforcement treatment of bridge engineering, it is necessary to choose the carbon fiber reinforcement technology reasonably. In actual construction, it is necessary to choose a good carbon fiber reinforcement material, and strictly follow the construction process to carry out construction operations, do a good job of maintenance treatment, to ensure that the project achieves the expected reinforcement effect.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.