Unidirectional Carbon Fiber Reinforcement -

Heavy Corrosion Structure

After the structural repair is completed, the main load-bearing structures such as frame columns and beams are reinforced with carbon fiber cloth. Since the operating load and other conditions of the structure have not changed, refer to the original design drawings of the structure and the results of on-site inspections to determine the bonding method and the amount of carbon fiber cloth.

Project Overview

The salt-making workshop of a salt and salt factory was built in 1989. It is a reinforced concrete frame structure with 3 floors, 49 meters long from east to west, 17 meters wide from north to south, and has a building area of about 2,100 square meters. Although it has not been put into use for a long time, due to the special use environment of the salt workshop, the structure of the plant has been seriously damaged by corrosion.

Destruction status and cause analysis

Most of the columns, beams, and slab components in the workshop have experienced different degrees of damage, which are mainly manifested as concrete cracking, crumbing, pulverization, spalling, corrosion of steel bars, and exposure. The destruction of the entire plant was shocking. A large amount of concrete peeled off, and many unflaked parts were already corroded, the tentacles were broken, and many steel bars were almost completely broken.

According to statistics, beams, columns, slabs and other components that have been damaged account for about 60% of the entire workshop. About 40% of the components are seriously damaged, the concrete is cracked and peeled, the shape of the components is very incomplete, the maximum cross-sectional loss exceeds 30%, and the structural rigidity is greatly reduced. In severely corroded parts, the cross-section loss of steel bars exceeds 60%. After preliminary inspection, the concrete strength has dropped by about 30%, and the carbonization is serious.

The damage to the plant structure is extremely serious and it is already extremely unsafe. It must be reinforced as soon as possible.

Structural strengthening reinforcement plan

After the structural repair is completed, the main load-bearing structures such as frame columns and beams are reinforced with carbon fiber cloth. Since the operating load and other conditions of the structure have not changed, refer to the original design drawings of the structure and the results of on-site inspections to determine the bonding method and the amount of carbon fiber cloth. All cloths are made of 300g high-strength grade I unidirectional carbon fiber cloth.

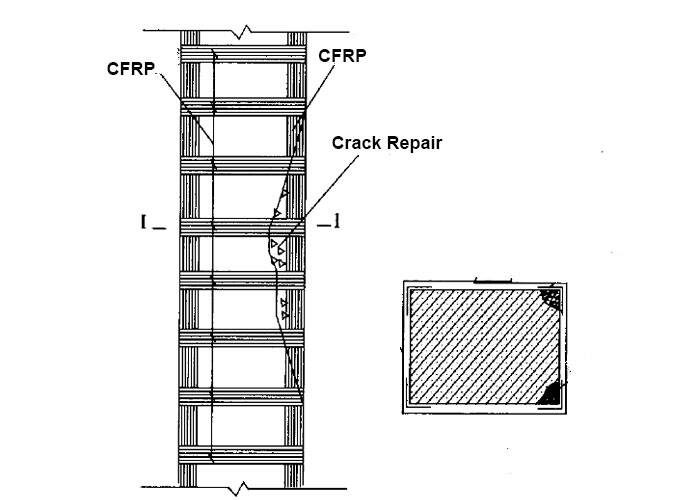

Paste the main stress cloth on the four corners of the frame column along the column axis. Then glue the carbon fiber cloth to seal the hoop around the entire length of the column. Wrap the longitudinal cloth strips in the inner layer, the cloth hoop is a single layer, with a width of 150 mm and a spacing of 300 mm, evenly distributed along the length of the column, and overlapped by 200 mm at the ring closure

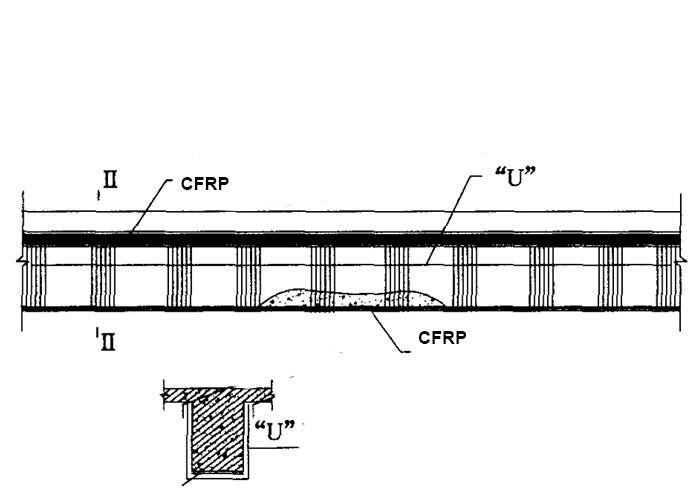

Stick carbon fiber cloth on the bottom surface of the frame beam along the length direction as the main stress cloth. Paste the "u"-shaped cloth hoop in the direction of the beam length. Each cloth hoop is a single layer, 150 mm wide and 300 mm apart, evenly distributed. The longitudinal carbon cloth at the bottom of the beam is wrapped in the inner layer, and the "U"-shaped cloth hoop is pasted up to the root of the slab bottom. On the top of both sides of the beam, close to the bottom of the plate, stick a layer of 150 mm carbon fiber cloth bead along the length of the beam, and press the end of the "U"-shaped cloth hoop on the inside.

Conclusion

(1) The structure of the plant has been in operation for 4 years since it was reinforced. The reinforced structure has no new damage, and it is intact as before. The reinforcement effect is good, indicating that the design ideas and construction methods are accurate and effective.

(2) Carbon fiber materials not only have excellent corrosion resistance, but also have unique advantages in construction. They are safe, reliable, fast and convenient, and are very suitable for structural reinforcement in similar severely corrosive environments.