Building strengthening

carbon fiber(CFRP)

By externally bonded carbon fiber fabric(CFRP) to the bottom of the slab, the load-bearing capacity of the floor slab is increased, and the deformation of the hollow floor slab is reduced.

Project Overview

A residential building of the electric power plant belongs to a six-story brick-concrete structure, using prestressed concrete hollow floor slabs, which was completed and put into use in December 1985. It was used normally before 1996, and cracks were found in some floors afterwards. The crack width was in the range of 0.4 to 1.0 mm.

There are two reasons for the crack:

In the course of years of use, the foundation compression produces a certain degree of uneven settlement;

In recent years, due to the rise of home furnishing, some families have renovated the house, purchased furniture, pasted floor tiles or marble slabs, and caused excessive load on the floor slab, causing cracks in the floor slab. The existence of cracks seriously affects the bearing capacity and integrity of the floor slab, and the existing floor slab must be reinforced.

According to the requirements of the residents, the rooms shall be restored to their original state after the floor slab is strengthened, which will not affect the use function and the normal life of residents. To this end, after many studies and analysis, decided to adopt crack injection and paste high-strength carbon fiber(CFRP). On the one hand, the grouting is used to seal the joints, block the passage of harmful media corroding the steel bars, and bond the cracked concrete to make the floor slab as a whole and improve its durability. On the other hand, the use of high-strength non-metallic fiber materials (such as carbon fiber, glass fiber, etc.) has the advantages of high strength, high efficiency, corrosion resistance, light weight, easy construction and so on. By affixing carbon fiber cloth to the bottom of the slab, the load-bearing capacity of the floor slab is increased, and the deformation of the hollow floor slab is reduced.

Carbon fiber reinforced polymer(CFRP) strengthening

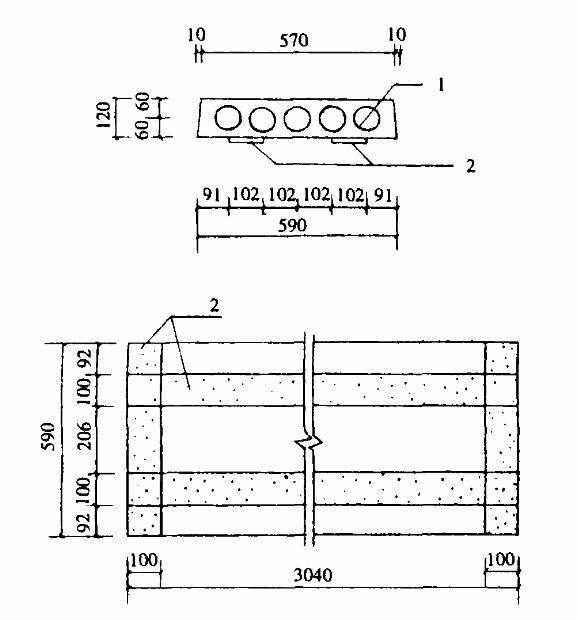

Paste two 100mm wide carbon fiber cloths along the long direction of the floor to strengthen the mechanical performance of the floor. And stick a 100mm wide carbon fiber cloth on the end to strengthen the end anchor. Each carbon fiber cloth is pasted in two layers.

Structural reinforcement effect

After one year of carbon fiber reinforcement, the bond between the carbon fiber cloth and the floor slab was good, and there was no flaking between the structural adhesive, the carbon fiber cloth and the concrete, and the floor slab has no cracks.

Conclusion

(1) Carbon fiber composite reinforcement technology is a new type of reinforcement technology emerging in recent years. Carbon fiber cloth has a high strength-to-weight ratio, excellent corrosion resistance, light weight, and hardly increases the structural load. Using it to reinforce reinforced concrete structures can effectively improve the load-bearing capacity of the components, strengthen the integrity and durability of the structure, and be safe and reliable.

(2) The construction process of pasting carbon fiber cloth is simple and quick, and the construction period is short. After the interface agent is applied to the carbon fiber cloth after pasting, the plastering operation can be directly carried out, which is convenient for the operation of subsequent jobs. Therefore, the carbon fiber cloth reinforcement method has more advantages than other methods, and has a very popular value.

(3) The carbon fiber material is subjected to unidirectional stress, which is consistent with the stress of structural members of this project, so it is more scientific and reasonable.

(4) It should be noted that carbon fiber can be used for flexural, shear and seismic reinforcement of concrete structures, but it is not suitable for concrete members that are severely cracked due to excessive deformation due to insufficient rigidity. When used for torsional reinforcement, although it can play a role, it is not economical. Therefore, when the carbon fiber reinforcement method is used, it should be analyzed according to the stress characteristics of the structure, and the trade-offs should be made.