Bridge strengthening

Externally bonded carbon fiber fabric for strengthening the bridges

For the reinforcement of highway bridges damaged by fire, or other reasons to improve the bearing capacity, the commonly used method is to stick carbon fiber fabric for strengthening.

Preface

In recent years, there has been a continuous occurrence of bridge damage caused by fire accidents. Generally, the concrete spalling of slab beam, cap beam and pier column will cause the section to become smaller. In severe cases, the bare steel bars, prestressing loss of prestressed steel bars, plate beam deflection increases, resulting in tensile cracks at the bottom of the plate beam, and so on. After the accident, first of all, according to the actual situation on the spot, it is necessary to analyze the time and temperature of the fire, judge the damage of the bridge and the reduction of the bearing capacity, so as to reinforce the bridge and reduce the loss caused by the fire to the minimum.

Analysis of bridge damage after fire

1.1 concrete damage

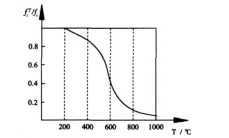

In case of fire, the first damage is the concrete. The strength of the concrete will be lost after high temperature. It can be found that when the temperature is lower than 300 C, the cement stone crystal does not change, only the internal non-bound water evaporates, and the thermal expansion coefficient of aggregate and cement stone is different, resulting in microcracks, and the strength of concrete is slightly reduced. When the temperature is between 300 and 600, the calcium hydroxide in the cement paste is dehydrated and decomposed, the crystal is slightly damaged, the cement paste begins to loosen and the concrete strength decreases. The dolomite and calcium carbonate in concrete begin to decompose when the temperature is between 600 and 800 degrees Celsius, the aggregate is no longer stable, and the compressive strength of concrete decreases sharply. When the cement paste is exposed to high temperature above 800 C, the cement paste becomes discontinuous agglomerate and the strength of concrete is basically lost. The effect of temperature on strength is shown in the diagram.

In fact, when the temperature is not too high, the concrete may burst and spall because of thermal expansion. When water is used to extinguish fire, the hot concrete surface is cooled rapidly by water, resulting in the difference of internal and external stresses of concrete members, which will aggravate the spalling of concrete. Therefore, the main damage of bridges in fire is the explosion and spalling of concrete, resulting in the reduction of the thickness of the protective layer, and even the bare reinforcement. At the same time, the section area of the member decreases. For the plate beam, the bending stiffness decreases, the deflection increases, and the tensile cracks appear at the bottom of the plate. Unflaked concrete can also become loose due to high temperatures, reduced strength and durability, internal steel corrosion is easy, and other associated negative effects.

1.2 steel bar damage

As time goes on during the fire, the steel bar will be gradually heated, especially after the protective layer is peeled off. The strength of reinforcing bars varies little at 200 degrees Celsius, and then decreases. The ultimate strength, yield strength and elastic modulus of reinforcing bars decrease with the increase of fire temperature, and soften at 450 C. When the temperature reaches 600 700 C, the inner crystal structure of reinforcing bars changes, which results in a very serious reduction of strength and elastic modulus and a loss of about half of strength. After cooling down, the strength of the steel restores partially, but the internal crystal rearrangement, yield strength and ultimate strength decrease, ductility increases. If water is used to extinguish the fire, the steel bar will go through the quenching process and become brittle. Prestressed steel bars and prestressed steel hinges have higher carbon content and are much more affected by fire than ordinary steel bars. High temperature relaxation will cause great prestress loss. If the protective layer is completely stripped bare, the steel bar will be directly exposed to fire, and the surface will be oxidized and rusted. If it is not treated in time, the corrosion of the steel bar will develop rapidly and affect its strength.

1.3 loss of cohesive force between reinforced concrete

Because of the large thermal expansion coefficient of the steel bar, the bonding force between the steel bar and the concrete is strengthened initially because of the tighter bonding between them. However, with the fire damage of cement paste structure, the bonding force is gradually destroyed, and the explosive spalling of concrete protective layer, which causes the bonding force to be greatly reduced.

Strengthening technology for bridges after fire

Slab beam reinforcement

In case of fire, the slab beam will generally appear concrete bursting and spalling, and not spalling also become loose, so the reinforcement of slab beam first need to cut loose concrete. If the spalling condition is serious and the steel bar is bare, anti rust treatment is needed. After a solid structural layer, it is necessary to restore the section thickness with repair mortar. When the spalling is not serious, it can be directly repaired with repair mortar. When the thickness of peeling layer exceeds 3-4 cm, it is difficult to repair directly. The steel bar can be planted at the bottom of the board, then the steel bar net or wire mesh can be hung up to repair the original section thickness. If the steel bar is exposed, rust removal and rust inhibitor should be first applied to the steel bar and then repaired to the original section thickness.

Since the strength of steel bars in slab and beam often decreases after fire, the degree of reduction can be determined according to the fire temperature and duration, and then the reinforcement design to improve the bearing capacity can be made. Concrete reinforcement measures can be used by sticking steel plate or carbon fiber fabirc. Because carbon fiber reinforcement has the advantages of high strength, light weight, corrosion resistance and durability.

Cover beam reinforcement

The bending moment and shear force of the cap beam are relatively large, and the cap beam is often fired on three sides, so the bending capacity and shear capacity of the cap beam decrease sharply after concrete burst and spalling. In order to improve the flexural capacity of the cap beam, the "U" shaped carbon fiber fabric should be attached to the bottom of the cap beam, similar to stirrups to enhance its shear capacity.

Pier column reinforcement

The piers of girder bridges are usually cylindrical columns with longitudinal reinforcements and spiral stirrups. The most likely damage to the piers during fire is the spalling of the protective layer, even the bare steel bars, and the concrete in the more serious stirrups also burst. Therefore, the bearing capacity of pier columns is reduced, and the reinforcement measures usually include restoring the section size and strengthening the bearing capacity. At present, the common reinforcement method of bearing capacity in engineering is to use fiber cloth around the sticking reinforcement method, so that the internal concrete in the three-dimensional compression state, improve the bearing capacity of piers. Other studies have shown that the seismic performance of columns strengthened with carbon fiber fabric is greatly improved.

Summary

For the reinforcement of highway bridges damaged by fire, or other reasons to improve the bearing capacity, the commonly used method is to stick carbon fiber fabric for strengthening.