Retrofitting and repairing bridge cracks

carbon fiber reinforced polymer strengthening

The carbon fiber reinforced polymer bonded on the tensile surface of the reinforced concrete hollow slab structure of the bridge to form an integral part with the bridge structure, and together with the external force, it can effectively reduce the stress of the steel bar, effectively suppress the cracks, and play a role in strengthening the bridge structure.

1 Introduction to the project

After a certain expressway was put into operation for a period of time, due to the rapid growth of local traffic and the heavy load of vehicles, many cracks appeared in the bridge deck pavement and bottom of the bridge during the use of the bridge. The bridge design uses two left and right frames, each with 19 spans. Both the left and right are newly built bridges, the upper structure is made of reinforced concrete hollow slab structure, and the lower structure is made of piled pier. The design load of the bridge is steam-20 tons, hanging-100 tons; the left bridge skew angle is 12 °, the right bridge skew angle is 0 °; the bridge span combination is 19 × 15.4m; the total width of the deck is 21m.

2. Disease survey

(1) A large number of cracks were found on the bridge deck pavement and the bottom of the slab, mainly cracked longitudinally along the hinge joint, and there is a trend of further expansion, which requires reinforcement.

(2) In the middle of the bridge, the concrete ends are partially damaged, the steel bars are corroded, and there are a lot of cracks, which will have a great impact on the stability of the bridge structure.

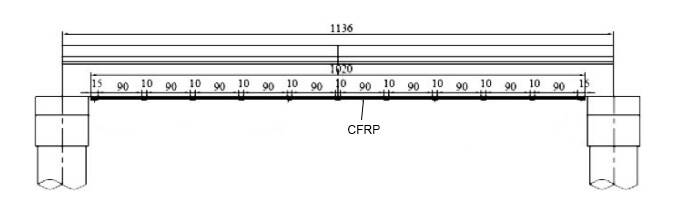

3. Carbon fiber reinforced polymer(CFRP) strengthening

The carbon fiber cloth and the concrete are integrated into a whole, which strengthens the bridge structure. Carbon fiber cloth has high strength and elastic modulus, which can effectively make up for the lack of tensile strength of reinforced concrete structures. In addition, when the carbon fiber cloth is subjected to temperature stress, the temperature stress generated is far less than its ultimate strength and has little effect. The carbon fiber cloth is pasted on the tensile surface of the reinforced concrete hollow slab structure of the bridge to form an integral part with the bridge structure, and together with the external force, it can effectively reduce the stress of the steel bar, effectively suppress the cracks, and play a role in strengthening the bridge structure.

4. conclusion

Based on the carbon fiber used in the construction of existing highway bridge reinforcement construction, and the dynamic and static load tests of the reinforced bridge, and the analysis of the data obtained by the test, the following conclusions were obtained:

(1) Through the static load test on the mid-span deflection of the bridge before and after reinforcement, the maximum value of the mid-span deflection after reinforcement is -1.96mm, which is less than the theoretical calculation value, the safety reserve is sufficient, and the reinforcement effect is obvious.

(2) Through the static load test on the strain of the bridge before and after reinforcement, the maximum value of the mid-span strain after reinforcement is 63.6, which is less than the theoretical calculation value, the safety reserve is sufficient, and the reinforcement effect is obvious.

(3) Strengthen the reinforced concrete hollow slab of the bridge by using carbon fiber reinforcement technology, and analyze the reinforcement effect in combination with the results of dynamic load test and static load test. It shows that after reinforcement, the dynamic performance of the bridge is effectively improved, and the bridge cracks are effectively repaired.