Gulou overpass retrofitting

Prestressed CFRP laminate

The prestressed carbon fiber plate reinforcement construction method belongs to the external prestressed reinforcement method, which is a high-quality reinforcement method based on the concept of prestressed reinforced concrete.

Overview of the overpass

Gulou Overpass is a three-story directional clover leaf interchange interchange located at the intersection of Xinhua Street and Zhelimu Road in Hohhot. It is composed of seven parts on four main lines and three ramps. The design car load level is steam-20 tons, hanging-100 tons, and the daily traffic is busy.

The bridge was built in 1997 and has been in service for more than 20 years. A safety inspection of the bridge structure in 2012 found that there were diagonal cracks at the ends of the webs of some of the slabs and beams, there were signs of water seepage between the beams, cracking and spalling of the concrete, exposed corrosion of the steel bars, cracks in the pits and grooves of the deck, and lateral cracking problem. One of the main lines of the prestressed continuous box girder floor had network cracks, and some of the cracks exceeded the limit, which was rated as unqualified. The continuous box girder must be strengthened to improve its bearing capacity and meet the original design load bearing capacity requirements.

Solution

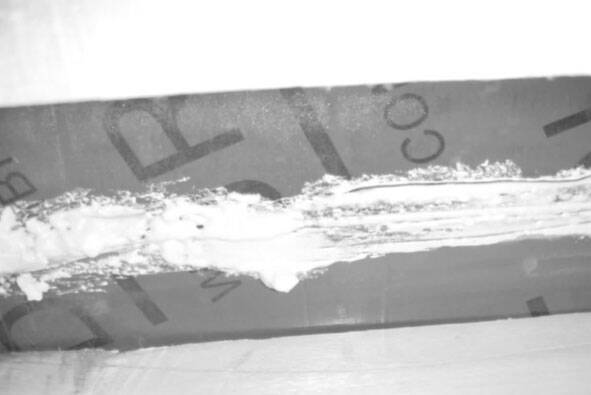

The phenomenon of insufficient prestress of this bridge is manifested by the fact that there are large-scale network cracks in the bottom of the continuous box girder, and the width of the transverse cracks mostly exceeds the crack width limit specified in the code. At the junction of the outer web and bottom plate of the box girder, an "L"-shaped crack appeared, and the crack width mostly exceeded the crack width limit specified in the code (see Figure 1).

Crack

Considering various factors, it was decided to adopt the method of bonding prestressed carbon fiber plate to the bottom of each prestressed continuous box girder beam for reinforcement.

The prestressed carbon fiber plate reinforcement construction method belongs to the external prestressed reinforcement method, which is a high-quality reinforcement method based on the concept of prestressed reinforced concrete. It can take advantage of the characteristics of carbon fiber materials such as light weight, high strength, corrosion resistance, etc. It also has the advantages of simple construction operation, fast construction speed, easy quality assurance, beautiful reinforcement effect, good durability and low maintenance cost in the later stage.

Construction process

1 Crack injection repair

Before tensioning the prestressed carbon fiber board, the mesh cracks and "L" cracks on the surface of each span box beam must be closed and repaired. The bridge uses automatic low-pressure infusion to close the structural cracks. After removing the dust and other debris in the concrete surface and cracks, install the grouting nozzle at 25cm intervals (see Figure 2), and then close the cracks outside the grouting nozzle (see Figure 3).

Install the injection nozzle

Closed crack

After the sealing material is hardened, insert an infusion device for infusion, observe the volume of colloid in the infusion device until it no longer shrinks, indicating that the crack is filled or the liquid agent has solidified, and the infusion can be stopped (see Figure 4). When the adhesive reaches the curing time, the grouting nozzle seat can be removed and the sealing material can be removed.

crack injection

2 Leveling of concrete at the bottom of the beam

Since the two-span original structure lacking prestress of the bridge in this project is provided with pre-camber, and both are greater than 5 cm, it is impossible to directly perform the construction of the carbon fiber board, and the pre-camber of the beam bottom needs to be treated. After a comprehensive analysis, considering the cost and technical requirements, the self-leveling fine stone concrete was finally used to level the beam bottom. In order to make the bottom surface of the original beam and the newly poured self-leveling fine stone concrete firmly bonded, the bottom surface of the original beam needs to be chiseled (see Figure 5). Before the formwork is constructed, check whether the planted reinforcement is firm and reliable (see Figure 6. Figure 7). The double-sided sponge is used to tightly seal the formwork during installation to ensure that the self-leveling mortar casting process does not cause expansion and leakage (see Figure 8). The pouring process should be formed at a time, and the construction rest should not exceed 2h.

Chiseling of the original beam

anchoring with HM-500

3. Installation of prestressed carbon fiber plate

3.1 positioning

Before installing the anchor, it is necessary to use a steel bar detector to detect the location of the original steel mesh to determine the installation position of the anchor. Then measure the center distance between the fixed end and the tension end cavity, accurately mark the location of the anchor hole, and pop out the center line and edge line of the carbon fiber board, the edge line of the anchor and the center line of the bead.

3.2 Grooving and drilling

After the positioning work is completed, use the cutting machine to cut out the anchor groove according to the lofting position, and repair and smooth it with repair mortar. Drill tension, fixed-end chemical anchor holes and bead chemical anchor holes according to the marked anchor holes, and clear the anchor holes (see Figure 9).

3.3 Planting anchor

Install anchor support anchor bolt before planting, wipe the hole wall with acetone or industrial alcohol before planting, and do not disturb within 12 hours after planting. Install and fix the anchor support at the tensioning and fixed ends to ensure that the anchoring blocks at the tensioning ends can move freely forward and backward.

3.4 Installation and tension of prestressed carbon fiber board

Install the carbon fiber board into the support at both ends, and install high-strength screw, washer, nut, block and jack in sequence at the tension end. The force direction of the jack should coincide with the center line of the carbon plate, and the preparation is ready for pretensioning (see Figure 11).

Carbon fiber plate pretensioning

After unloading the pretension, apply primer to the cleaned base surface. Apply special structural adhesive evenly on the surface of the carbon plate (see Figure 12).

Apply carbon fiber plate glue

Subsequent formal tensioning is carried out step by step, each tension needs to be maintained for 3min ~ 5min, and the corresponding tensile force and elongation are recorded at the same time, and then the lower tension. After the tension is completed, tighten the nut, remove the jack, cut off the excessively long tension screw, and press the carbon plate bead to lighten it slightly, and clean the structural glue extruded from the edge of the carbon plate.

prestressing CFRP plate system

Finally, the anchor is sealed and protected, and the surface of the carbon plate is protected. The installation of the prestressed carbon fiber board is completed (see Figure 13).

Surface protection of prestressed carbon plates

Summary

There are many advantages to using prestressed carbon fiber board technology to strengthen bridge beams. The construction period is short, the secondary damage to the beam is small, the material is light, the load on the beam is small, the construction quality is easy to control, and it is economical and environmentally friendly.