Reinforcement of ordinary hollow slab pedestrian bridge

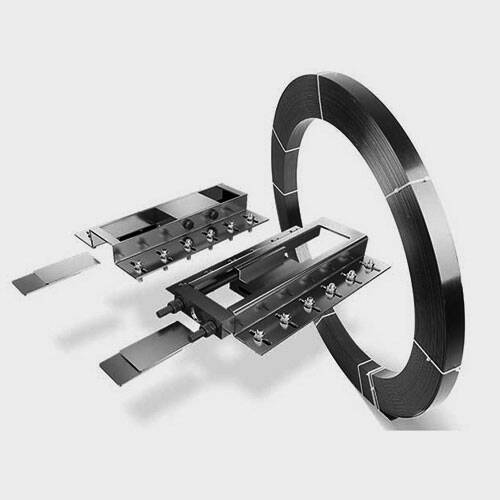

Double-layer carbon fiber laminate

Reinforced bridges with prestressed carbon fiber plates can not only meet the requirements of the design load standard, but also limit the development of bridge cracks and greatly improve the durability of the bridge.

Project Overview

The Luzhou section of the Chengzi Luchi Expressway is the main road between Sichuan and Guizhou, with heavy traffic and increasing traffic since its opening. In order to facilitate the passage of villagers on both sides of the expressway, a number of reinforced concrete hollow slab footbridges were built on this section of the expressway.

Cheng Since the Luzhou section of the Luchi Expressway was officially opened to traffic one year later, the inspection agency conducted the first regular inspection of the bridges across the line. It was found that the main components of the pedestrian bridge at K248+115 have large defects, which affect the function of the bridge or affect the bearing capacity.

The pedestrian bridge at K248+115 connects the sugar house foundation and Qinglongzui with a total length of 50m. The horizontal layout of the bridge deck is: 0.25m (anti-throw net) + 3.0m (bridge deck sidewalk) + 0.25m (anti-throw net) = 3.5m. The superstructure is 2x20m simple-supported ordinary reinforced concrete hollow slab with concrete design strength C3 0, prefabricated hoisting construction. The substructure abutments use gravity abutments to expand the foundation. GJZ150x250 x35 supports are installed at the abutments, for a total of four. Column type pier, enlarged foundation, and GJZ150x250x28 supports at the bridge pier, a total of four.

Diseases and causes of superstructure

The main defects and diseases of the hollow slab of the superstructure are as follows:

(1) A large number of vertical cracks in the whole bridge on the side of the beam are 240, with a total length of 96m and a maximum width of 0.4mm

(2) There are a total of 150 transverse cracks in the bridge at the bottom of the beam, with a total length of 150m and a maximum width of 0.22mm.

The winged hollow slab of the superstructure produced a lot of vertical cracks and transverse cracks, and some cracks exceeded the limit. This may be due to poor design considerations, inadequate construction control, poor maintenance management, and aging concrete. The structure itself caused holes, spalling, and corrosion of steel bars to varying degrees. These defects reduced the strength of the concrete. Through field drilling, it was found that the steel bars were improperly placed during the construction process and were biased toward the neutral axis.

In summary, under the action of load, the positive bending moment of the hollow slab floor in the span of L/4~3L/4 is large, which leads to structural cracks and stress cracks. That is, during the operation, the anti-cracking safety reserve in the direction of the main tensile stress of the beam bottom is insufficient, resulting in a large number of cracks.

Main beam reinforcement plan

The main purpose of reinforcement is to restore or improve the bearing capacity and service performance of the bridge as soon as possible, so that it meets the load standard of "crowd load 3.5kN/m2", and at the same time limits the crack width of the structure under the use of load, fundamentally ensuring structural safety , improve the durability of components and extend the service life of the bridge.

For the reinforcement of the bridge, the final choice is to paste prestressed carbon fiber laminate.

Due to the large number of transverse cracks in the bottom plate of the hollow slab and the large distribution range, the prestressed carbon fiber laminate is pasted. The application of prestressing can improve various indicators of the structure during normal use, reduce the crack width or force crack closure, and improve the mechanical performance of the plate beam. And the prestressing effect is equivalent to applying a reverse load to the plate beam. Part of the internal force under constant load is offset, the stress value of the main reinforcement in the tensile zone and the stress amplitude under dynamic load are reduced, and the long-term fatigue performance of the structure is improved. After being strengthened with this scheme, the bridge beam can not only meet the requirements of the design load standard, but also limit the development of bridge cracks and greatly improve the durability of the bridge. Since the carbon fiber material itself is a corrosion-resistant material, the maintenance in the later stage of reinforcement is less, which saves the maintenance cost.

The cost of prestressed carbon fiber laminate reinforcement is almost the same as the cost of steel plate reinforcement. However, because it is actively reinforced, the prestressing force is applied to the main beam with carbon fiber plates to rapidly and significantly improve the deformability of the original structure, reduce and close the cracks, and significantly increase the load-bearing capacity of the structure. In addition, this method has a fast reinforcement construction speed, which can complete the reinforcement of the main beam in a short time, so as to achieve the purpose of rapid opening of traffic.

Reinforced with prestressed carbon fiber laminate

The carbon fiber laminate used for reinforcement has a width of 50 mm and a thickness of 2 mm. Each prestressed carbon fiber laminate belt is composed of double-layer carbon fiber laminate. Each hollow laminate of the bridge is provided with two double-layer prestressed carbon fiber laminate belts with a total applied tensile force of 400 kN, and the effective prestress of the prestressed carbon fiber laminate is 1000 MPa. Corresponding protective measures should be taken during the stretching process.

In conclusion

The double-layer prestressed carbon fiber lamiante significantly improves the cracking load, yield load and ultimate bearing capacity of the reinforced structure. It is very suitable for the flexural reinforcement of bridges, which can directly and effectively improve the structural bearing capacity. It has outstanding advantages in suppressing crack development and improving the flexural bearing capacity of components. Therefore, the use of carbon fiber laminate reinforcement will be increasingly favored by the bridge and beam engineering community.