Cracking cast-in-place floor strengthened

Floor strengthened by CFRP sheets

The use of carbon fiber sheet(CFRP) to reinforce cast-in-place cracked floor slabs can effectively enhance the flexural rigidity of the reinforced members, improve the flexural bearing capacity and reduce deformation.

Project Overview

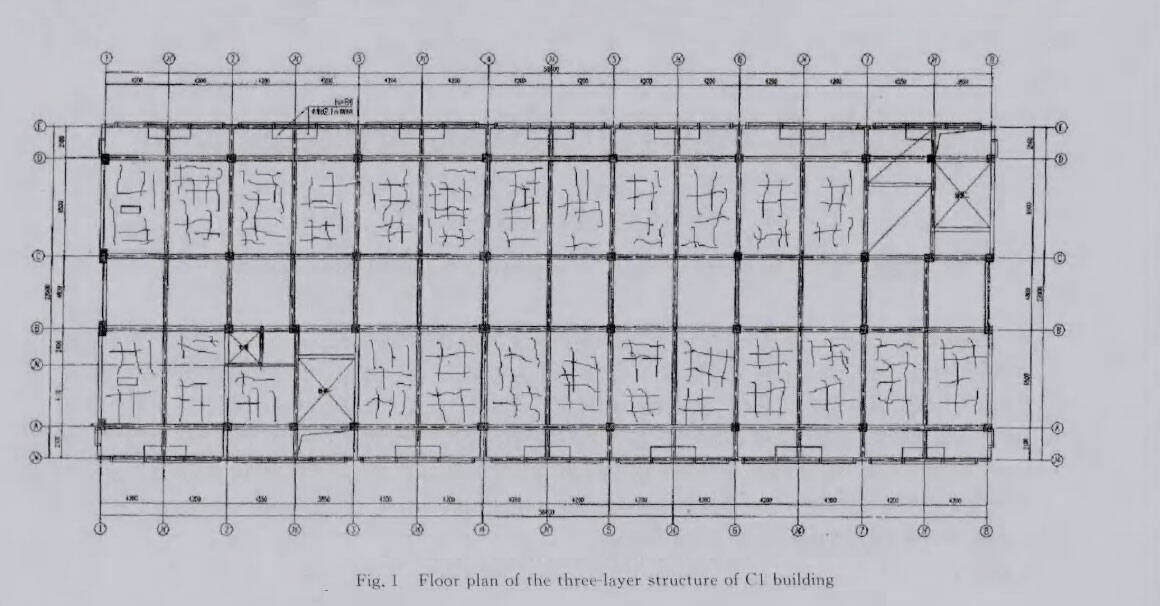

Building Material Market C1 has a three-story frame structure, with a construction of 22 000 mm horizontally and 58 800 mm vertically, with a construction area of 3 762 m. The three-layer structure (two-layer top) cast-in-place slab is designed to be 100 mm thick and the concrete strength level is C25.

About three months after demolishing the three-story structural slab of the project, it was found that the three-story structural cast-in-situ slab has a large area of cracking, most of which are through cracks, and there are water marks after pouring rain. The crack presents the following characteristics:

(1) The vast majority of cracks are grid-like, with horizontal and vertical shapes.

(2) Cracks are generated under the weight of the floor, and no load is applied before cracking.

(3) The entire three-story structural floor is generally cracked, and the cracked floor area accounts for about 80% of the floor area. The floor plan of the three-story structure of Building C1 is shown in Figure 1.

Causes of cracks

Considering the comprehensive factors of crack distribution area, crack shape, crack width, construction environment, finished product protection and other factors, the formation of cracks in this floor slab is not caused by structural or construction reasons, mainly caused by the plastic shrinkage of concrete. There may be the following reasons:

(1) Too much fly ash is used in the actual concrete mix ratio;

(2) The actual concrete water-cement ratio is too large;

(3) The concrete supplier is a small local company, and the production is not standardized, and there may be mixed cement;

(4) The project uses river sand, which has large mud content and fine particles.

Carbon fiber strengthening the floor

Considering the large area to be reinforced and the tight construction period, in order to save investment, the carbon fiber cloth method with less technical difficulty and simple construction process is used for reinforcement.

First, epoxy resin slurry is used to pressure grouting the cracks. After grouting, use epoxy resin cement to smooth the seal at the grouting mouth. After sealing, perform surface treatment and brush the bottom resin. Then level the adhesive surface and brush with impregnated resin, and finally paste the carbon fiber cloth for surface protection.

According to the requirements, when reinforcing carbon fiber cloth, multiple orthogonal dense cloths should be laid on the board. A layer of carbon fiber cloth with a thickness of 0.167 mm is attached to the bottom of the floor slab of the project in both directions. The carbon fiber cloth is 100 mm wide and the center is 600 mm apart. As shown in Figure 6.

Conclusion and suggestion

Based on the analysis of the causes of cracks in the cast-in-place floor slabs and the evaluation of the effectiveness of carbon fiber cloth reinforcement, the following main conclusions can be obtained, and suggestions for construction and reinforcement are proposed:

(1) The use of carbon fiber cloth to reinforce cast-in-place cracked floor slabs can effectively enhance the flexural rigidity of the reinforced members, improve the flexural bearing capacity and reduce deformation.

(2) Through specific analysis of cracks in cast-in-place floor slabs in a project, it is shown that concrete shrinkage and cracking may occur due to improper use of concrete raw materials. However, after grouting and sealing the cracks on the floor of the project, the carbon fiber cloth was used to reinforce the two-way grid. After careful organization and construction, the project has been in normal use for more than a year and no cracks have occurred.