Yangtze River bridge, Jun Shan, Wuhan

After the construction period in November, Wuhan Junshan Yangtze River Bridge, the largest prestressed CFRP laminate project in China, was completed.

Horse Construction prestressing FRP laminate systems were used in Wuhan Junshan Yangtze River Bridge. This is not only the first super-large prestressing project contacted by Horse Construction, but also the largest prestressing FRP narrow plate project in China so far. After eleven months, please follow Horse Construction to review this great reinforcement project:

In 2017, more than 3200 sets of Horse Construction prestressing FRP laminate systems were used in Wuhan Junshan Yangtze River Bridge. This is not only the first super-large prestressing project contacted by Horse Construction, but also the largest prestressing FRP narrow plate project in China so far. After eleven months, please follow Horse Construction to review this great reinforcement project:

Wuhan Junshan Yangtze River Bridge is the fourth Yangtze River Bridge in Wuhan City. It is a cable-stayed bridge of super large highway in deep water. The bridge adopts two way 6 Lane layout, which is the first width of similar bridges in China.

During the 17 years since the Junshan Bridge was opened to traffic, the bridge structure has undergone a variety of harsh environment tests, especially the vehicle tonnage seriously exceeded the standard, the bridge deck temperature difference between day and night and other factors accelerated the overall aging of the bridge. Therefore, the military Hill Bridge in 2017 carried out a large-scale reinforcement and maintenance works.

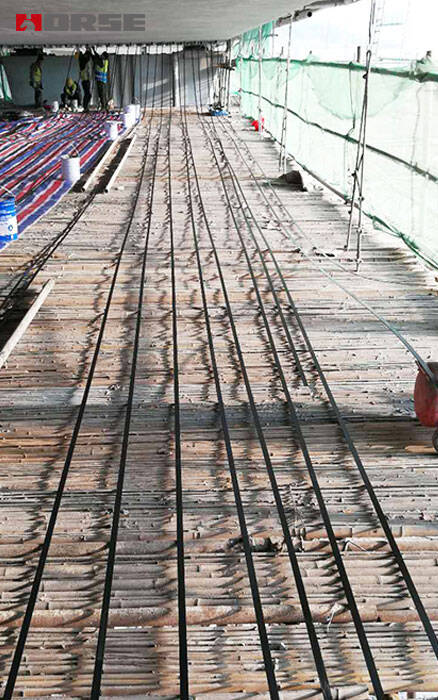

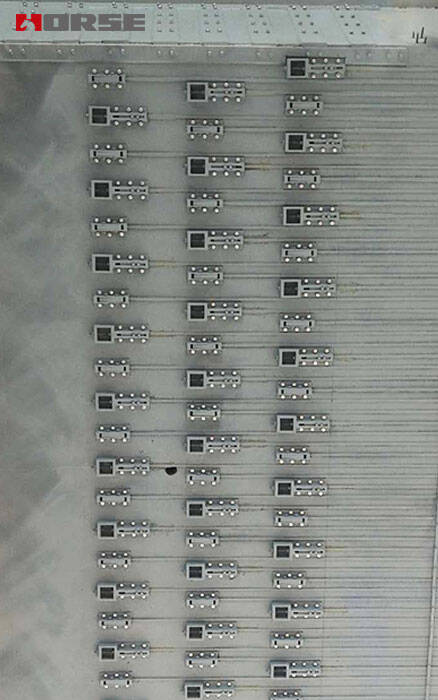

In order to meet the needs of strengthening the box girder, the design team adopted the design scheme of prestressed FRP laminate system. At the same time, because our anchorage has the characteristics of small groove and high anchorage efficiency, Horse Construction has won the tender and undertook a total of 46 bridges of 1380 meters, a total of 3220 sets of prestressed FRP laminate system supply tasks.

First of all, in terms of the overall design of the reinforcement project, the secondary cracking of CFRP is caused by the stress loss of the original prestressed strand, so the prestressed CFRP laminate system is used to compensate the stress loss. The design and calculation of the main process, similar to pasting carbon fiber composite, the main difference is that the crack and deflection calculation considers the effect of tensile stress.

Secondly, from the construction point of view, the design of the required carbon fiber composite board using 3x20mm carbon plate system, and take the form of staggered layout, to ensure the stability and safety of the overall force, is a military mountain bridge anchorage selection of a preferred scheme.

Preparation of reinforcement materials such as prestressed carbon fiber plates, carbon plate adhesives and sliders.

Positioning line

Drill hole for chemical rebar

Slotting

Slotting completion

anchorage install

prestressed carbon fiber laminate

install prestressed FRP laminate

install screw

slotting of prestressed FRP laminate

appling adhesive for prestressed FRP laminate

pretension

formal tension

step by step tension

tension complet

fix pressure bar

Remove excessive screw

coating

filish coating

Install aluminum cap