New construction and reconstruction of Century Lianhua

Carbon fiber reinforced plastics(CFRP) strengthening

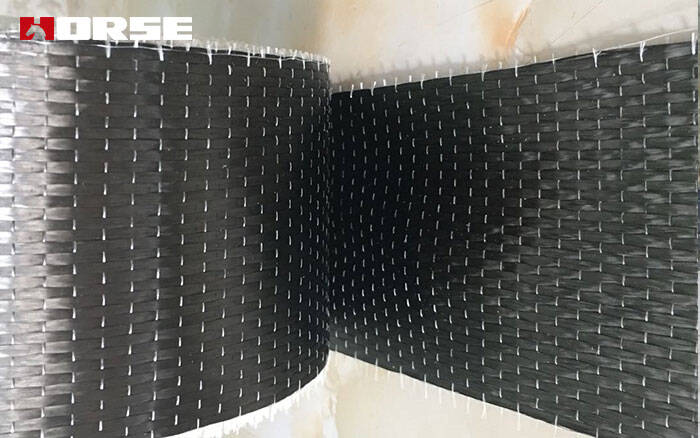

In this project, carbon fiber reinforced plastics(CFRP) strengthening beams, columns and other members were used, and good results were obtained.

Project Overview

The Century Lianhua Jining Store project is a new construction and reconstruction project, with a total construction area of about 25,000m, of which the reconstruction area is about 10,000m. After completion, it will be a commercial warehouse-type large-scale supermarket. Some beams, slabs, columns and other components have insufficient load-bearing capacity, and the structure has changed a lot. Therefore, the original structure needs to be reinforced and reformed.

If the traditional method of bonding steel reinforcement is adopted, the construction period is long, and many places are inconvenient for construction, and it is not easy to guarantee the quality. For example, the original buildings are all cylindrical, and the bearing capacity of some of the columns is insufficient. It is not possible to cast concrete by increasing the column cross-section. The sticky arc-shaped steel plate is not easy to guarantee the construction quality.

Therefore, in this project, carbon fiber reinforced plastics(CFRP) strengthening beams, columns and other members were used, and good results were obtained.

Technical characteristics of carbon fiber reinforcement

Compared with other reinforcement methods, carbon fiber reinforcement technology has obvious technical advantages.

(1) High strength and high efficiency.

(2) Corrosion resistance and durability.

(3) Do not increase the weight and volume of components.

(4) Wide application.

(5) Easy construction.

Carbon fiber reinforced plastics(CFRP) strengthening

(1) The use of carbon fiber cloth instead of longitudinal tensile reinforcement to reinforce reinforced concrete columns can effectively improve the normal section bearing capacity of the columns.

(2) As the number of layers of carbon fiber cloth pasted in the vertical direction increases, the effect of reinforcing and strengthening becomes more and more obvious. However, the number of layers of carbon fiber cloth does not increase linearly with the increase in the bearing capacity of components. As the number of layers of fabric increases, the load-bearing capacity of members gradually slows down. When pasting more than two layers of carbon fiber fabrics, a common work reduction factor needs to be considered.

(3) There is a size effect on the tensile strength of carbon fiber cloth. As the growth rate of the width of the fiber cloth increases, the ultimate tensile stress of the fabric decreases to a certain extent. Because the mechanical properties of different types of carbon fiber are different, the size effect coefficient should be determined according to the actual type of carbon fiber cloth.

(4) The reinforced concrete column reinforced with carbon fiber cloth positive section reinforcement is divided into two types under tension. One is that the concrete in the compression zone reaches the ultimate pressure strain and the component is destroyed. The second is that the carbon fiber cloth reaches the ultimate tensile strength at the section with the largest bending moment, causing the member to fail.

(5) Compared with the unreinforced column, the reinforced concrete column reinforced with carbon fiber cloth has cracks relatively late, and develops slowly, and the number of cracks is much larger. The width of the crack is much smaller than that of the unreinforced column, and the number of main cracks formed is also significantly reduced.

(6) When the strength of the component concrete is low, after being reinforced with carbon fiber cloth, its bending bearing capacity is significantly improved, up to 15%.

Conclusion

Century Lianhua Supermarket Renovation Project has been completed for 3 years, and the bearing capacity meets the requirements under the design load without damage and destruction. Observation results show that the beam-slab structure deformation also meets the requirements of the code limits.