Carbon fiber reinforced existing railway bridge

railway bridge strengthen

1) The bridge is reinforced with carbon fiber, the process is simple, and the construction period is short. After the completion of this project, after inspection and inspection, the carbon fiber and concrete were well bonded, and the expected effect was achieved, which ensured that the heavy truck safely crossed the bridge.

Introduction

In recent years, due to the increased power of trains and the effects and influences of various environmental factors, railway bridges will produce a series of diseases within the service period, such as deterioration of concrete materials, corrosion of steel bars and other diseases. At the same time, with the passage of time, a large number of railway concrete bridges will enter the aging period.

These factors have a greater impact on the safety, applicability and durability of the bridge structure. To different extents, the bearing potential of the bridge is reduced, and even the safe operation of the bridge is endangered. For these bridges, reinforcement is needed.

Project Description

The Melodian Xida Bridge is a steel-reinforced concrete T-shaped girder bridge on the Huangling-Li Zhanghe Railway Coal Transportation Line, with a span of 16m and a total of 8 spans.

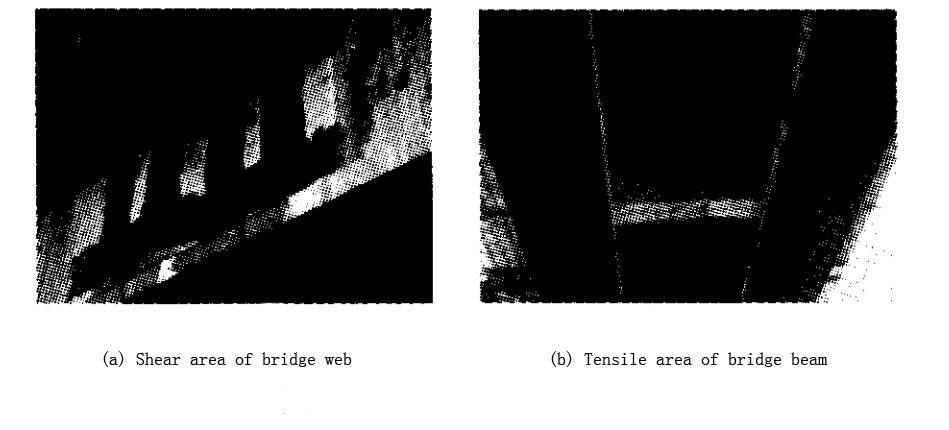

The number of cracks in the beams of this bridge is 201, with a total length of 214.5m, and the maximum width of the cracks is 0.2mm. They are distributed in the web shear zone and the beam bottom bending zone. Its load-bearing capacity is difficult to meet the increased capacity requirements, and beam reinforcement is required.

Reinforcement plan

The reinforcement solution adopted by the beam reinforced the main beam with carbon fiber(CFRP), and the horizontal and vertical carbon fibers were pasted to the shear zone of the 3/4 span of the bottom of the beam and the 1/4 span of the support.

1) Tension zone at the bottom of the beam. Two layers of carbon fiber cloth are glued to the bottom of the 16m main beam. The bonding range is from the middle of the span to one-third of each side. The width is the full width of the bottom of the main beam.

2) 1 / 4L shear zone of beam body web. Tape carbon fiber cloth is pasted at the position of 1 / 4L. The width of the carbon fiber cloth is 0.25m. From the junction of the beam flange and the web, stick the carbon fiber cloth vertically down on the beam web, then stick it to the bottom of the beam, and then stick it up to the other side of the web. The beam body 1 / 4L spans each side of the web with 3 carbon fiber sheets, and each beam has 12 sheets.

In conclusion

Through the theoretical analysis of the structure of the reinforced front and rear axle beams and the analysis of the field test results, the following conclusions can be obtained:

1) The bridge is reinforced with carbon fiber, the process is simple, and the construction period is short. After the completion of this project, after inspection and inspection, the carbon fiber and concrete were well bonded, and the expected effect was achieved, which ensured that the heavy truck safely crossed the bridge.

2) After reinforcement, the bearing capacity and dynamic stiffness of each bridge structure meet the requirements, and there is a certain reserve. The impact performance of the bridge meets the requirements of the specification, and the calculation results of the dynamic deflection show that the bridge still has a certain capacity for storage. After the reinforcement and maintenance, the workability of the bridge can be effectively improved to meet the capacity requirements.

3) Carbon fiber materials are highly resistant to corrosion and can be used to reinforce structures in special environments.