Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Carbon Fibre Reinforced Polymer (CFRP) Strengthening

Carbon fiber composite reinforcement technology has become one of the mainstream solutions for strengthening civil engineering structures due to its advantages such as high strength, lightweight, and convenient construction.

However, its long-term durability—that is, the ability of the reinforcement system to maintain its performance under complex environments and loads—is crucial to determining the lifespan and safety of the project. This article aims to systematically explore the core factors affecting the durability of carbon fiber reinforcement, potential degradation mechanisms, and strategies for improving durability.

I. Composition and Durability Challenges of Carbon Fiber Reinforcement Systems

A complete carbon fiber reinforcement system mainly consists of three parts: carbon fiber material (fabric or sheet), epoxy resin-based adhesive, and concrete substrate. The durability of the system depends on the durability of each component itself and the long-term stability of their interfacial synergy. The main challenges come from:

Environmental effects: temperature, humidity, ultraviolet radiation, and chemical corrosion.

Long-term loads: sustained stress and fatigue loads.

Accidental events: fire and impact.

II. Core Factors Affecting Durability and Degradation Mechanisms

1. Aging of Epoxy Resin Adhesives

The adhesive is the weakest link in the reinforcement system, and its aging directly determines the long-term performance of the CFRP-concrete interface.

* **Hydrothermal Aging:** Moisture and temperature are the main culprits accelerating aging. Moisture penetrates the adhesive layer, causing plasticization and hydrolysis of the epoxy resin, leading to a decrease in its glass transition temperature, modulus, and strength. In freeze-thaw cycles, the penetrated moisture freezes and expands, potentially causing internal cracking of the adhesive layer.

* **Creep:** Under continuous stress, epoxy resin adhesives undergo creep, leading to stress relaxation. Under long-term loads, this effect may cause stress redistribution between CFRP and concrete, reducing reinforcement efficiency.

2. Degradation of Interfacial Bond Performance

The bonding interface between CFRP and concrete is a key pathway for stress transfer.

* **Interfacial Debonding:** Moisture intrusion into the interface reduces the bond strength between the epoxy resin and concrete. Under the combined effects of stress and environmental factors, premature debonding failure of the interface may occur. Salt corrosion: In de-icing salt or marine environments, chloride ions and other substances can penetrate the concrete into the interface zone, potentially causing adhesive degradation or further damage to the concrete substrate.

3. Long-term performance of carbon fiber materials themselves:

Carbon fiber filaments are chemically stable and possess excellent fatigue resistance and corrosion resistance. However, their durability challenges mainly lie in:

* **Galvanic corrosion:** When carbon fiber comes into contact with metal (such as internal reinforcing steel) in the presence of an electrolyte (such as seeping salt water), a galvanic cell forms. The carbon fiber acts as the cathode, potentially accelerating the corrosion of the anode (reinforcing steel). Although the carbon fiber itself does not corrode, it can induce corrosion of the surrounding reinforcing steel, indirectly jeopardizing the overall structure.

* **UV degradation:** Direct exposure to UV light will degrade the exposed epoxy resin matrix, but has a limited impact on the carbon fiber embedded in the adhesive layer. This is usually addressed through a protective surface coating.

4. Continuous changes in the concrete substrate:

Even after reinforcement, the concrete substrate of the structure continues to change.

* **New crack formation: **Due to increased load or concrete shrinkage and creep, new cracks may form near the interface with the CFRP bond, leading to stress concentration and triggering delamination.

* **Progression of existing damage: **If the substrate is not properly treated before reinforcement, the loose concrete will not be able to provide a strong bond foundation.

III. Key Technical Strategies for Enhancing Durability

To ensure the long-term effectiveness of carbon fiber reinforced polymer (CFRP) systems, systematic protective measures must be implemented.

1. Strict Substrate Preparation: This is the first line of defense for ensuring long-term bond durability. Loose concrete must be thoroughly removed to expose a solid substrate, and sufficient surface roughening treatment must be performed to achieve mechanical interlocking.

2. Selection of High-Performance Adhesives: Select specialized epoxy resins with high glass transition temperatures, low water absorption, good toughness, and creep resistance. In humid, hot, or chemically corrosive environments, more durable resin systems such as modified epoxy or vinyl esters should be considered.

3. Application of a Comprehensive Protective System:

Weather-Resistant Coating: Applying a UV-resistant and abrasion-resistant protective coating (such as a polyurethane topcoat) to the CFRP surface is an effective means of protecting the adhesive from direct environmental corrosion.

Flame-Retardant Coating: For buildings with fire protection requirements, a fire-retardant coating must be applied to protect the CFRP in the event of a fire (its adhesive softens and fails rapidly at high temperatures).

4. Design Considerations and Detail Handling:

End Anchoring: By adding pressure strips or mechanical anchoring to the ends of the CFRP, peeling failure caused by stress concentration can be effectively prevented, significantly improving the reliability and durability of the system.

Appropriate Material Selection: In environments where electrochemical corrosion may occur, the use of an insulating layer (such as fiberglass cloth) to isolate the CFRP from the metal components should be considered.

IV. Durability Assessment and Long-Term Monitoring Long-term performance assessment of reinforced structures is crucial.

Non-destructive Testing: Regularly employ hammer impact testing (to detect hollow areas by sound), infrared thermography, or ultrasonic testing to detect defects such as delamination and voids between CFRP and concrete.

Long-Term Monitoring: Implanting or attaching intelligent sensing devices such as fiber optic grating sensors allows for real-time monitoring of CFRP strain changes, thereby assessing its long-term stress state and performance degradation, enabling predictive maintenance.

The durability of carbon fiber reinforcement is a complex systems engineering issue involving materials, interfaces, environment, and time. While carbon fiber itself possesses excellent durability potential, the long-term performance of the system largely depends on the stability of the adhesive, the integrity of the interfacial bond, and comprehensive protective design. By selecting high-quality materials, implementing rigorous construction processes, and applying effective protective and monitoring measures, the advantages of carbon fiber reinforcement technology can be maximized, ensuring the safety and reliability of the reinforced structure throughout its design service life.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

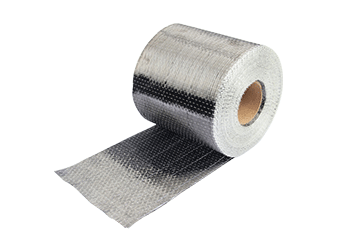

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.

High strength unidirectional carbon fiber fabric for concrete repair and structural strengthening