Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Carbon Fiber Plate Or Carbon Fiber Sheet?

The core differences between carbon fiber plates and carbon fiber cloth lie in their "shape, stiffness, and construction adaptability." Essentially, they are different molded products of the same material (carbon fiber) designed to meet different reinforcement needs.

I. Core Physical and Morphological Differences

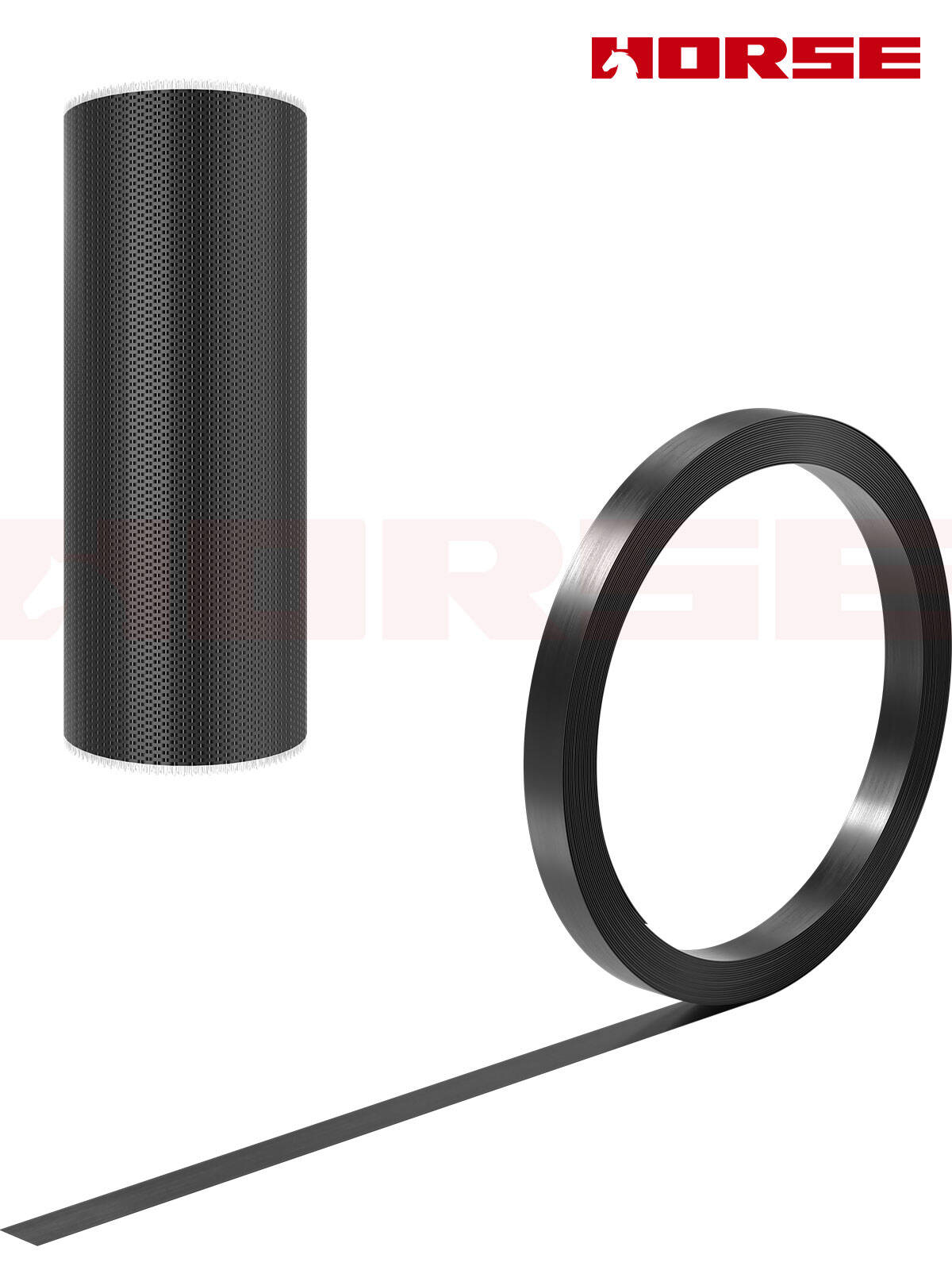

Carbon Fiber Plate: A rigid sheet material formed by pressing carbon fiber filaments and resin together. It has a thickness of 1.0–3.0 mm (national standard specification), a width of 20–150 mm, a fixed shape, high rigidity, and cannot be bent.

Carbon Fiber Sheet: A flexible fabric woven from carbon fiber filaments. It has a thickness of 0.111–0.666 mm (depending on the number of layers), a width of 100–1500 mm, and can be folded, bent, and conformed to complex curved surfaces.

II. Differences in Construction and Installation

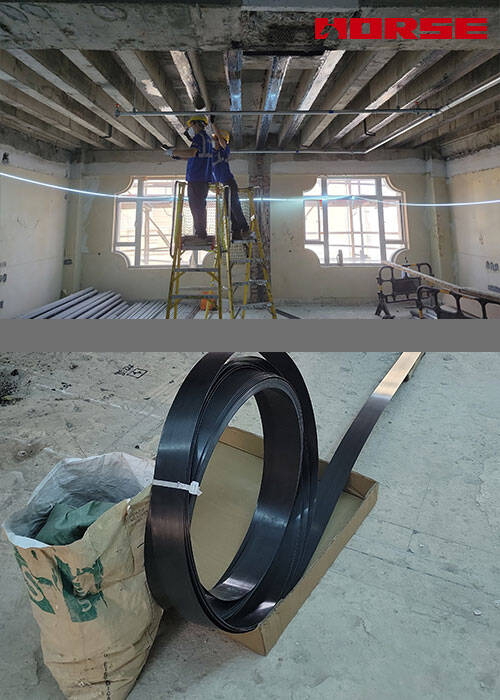

Construction Difficulty: Carbon fiber plates require precise cutting and positioning, relying on mechanical assistance for installation (such as bolt fixing and pressure strip tightening), and have high requirements for the flatness of the substrate (error ≤ 3mm); carbon sheet can be directly pasted by hand, with flexible cutting, and minor unevenness of the substrate can be filled with adhesive.

Splicing Method: Carbon fiber plates splicing requires special joints (such as overlapping steel plates, tenon joints), with splicing strength loss ≤ 10%; carbon sheet can be directly overlapped (overlap length ≥ 100mm), simple to operate, and with no significant strength loss.

Construction Efficiency: Carbon fiber plates are faster for large-area planar components (such as bridge main beams) (large single area, no need for individual pasting); carbon sheet is more efficient for complex components (such as irregular columns, curved beams) (strong adhesion, no need for custom-made irregular sheets).

III. Differences in Applicable Scenarios (The Most Core Difference)

Carbon fiber plates are suitable for:

Reinforcing heavy-duty components (such as bridge main beams and heavy beams in industrial plants), requiring a significant increase in bending and shear strength.

Structural deformation control (such as large-span floor slabs and bridges with excessive deflection), relying on high stiffness to suppress deformation.

High-altitude and open-air environments (such as bridges and cooling towers), where rigid structures offer stronger wind and vibration resistance.

Carbon fiber fabric is suitable for the following scenarios:

Complex-shaped components (such as irregular columns, pipes, and curved walls), the flexible fabric can be applied in all directions.

Local reinforcement (such as cracks at beam ends or damaged column corners) can be cut to size as needed, avoiding material waste.

Small spaces and narrow areas (such as basements and equipment rooms) require no large equipment and can be constructed manually.

Repairing minor load-bearing deficiencies or cracks (such as residential floor slabs and secondary beams) is convenient and cost-effective.

IV. Cost and Maintenance Differences

Cost: For the same reinforcement effect, carbon fiber plates cost 20%–40% more than carbon fiber cloth (due to more complex plate forming processes), but construction labor costs are 10%–20% lower. For large-area projects, carbon fiber plates offer better overall cost, while carbon fiber cloth is more economical for small-area localized reinforcement.

Maintenance: Both are corrosion-resistant and maintenance-free (service life 30–50 years), but carbon fiber plates, due to their high rigidity, are prone to localized cracking if the base layer settles unevenly. Carbon fiber cloth, with its high flexibility, adapts better to minor structural deformations and has a lower risk of detachment later on.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.