Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Why Do Carbon Fiber Test Tensile Strength?

The tensile strength of CFRP (carbon fiber reinforced polymer) is important in structural strengthening because it enables the material to resist high tensile stresses that can cause structural failure.

When a structure is subjected to loading, such as due to wind, seismic events, or heavy loads, it experiences tensile stresses that can cause cracks or other types of damage.

By adding CFRP to the structure, its tensile strength can be increased, allowing it to better resist these tensile stresses and prevent or limit damage. This is particularly important in structural strengthening applications where the goal is to improve the capacity of the structure to resist increased loads, such as in bridge or building retrofits.

The high tensile strength of CFRP also allows for the development of lightweight and durable strengthening systems. By using CFRP to strengthen structures, the overall weight of the structure can be reduced, resulting in cost savings and improved performance.

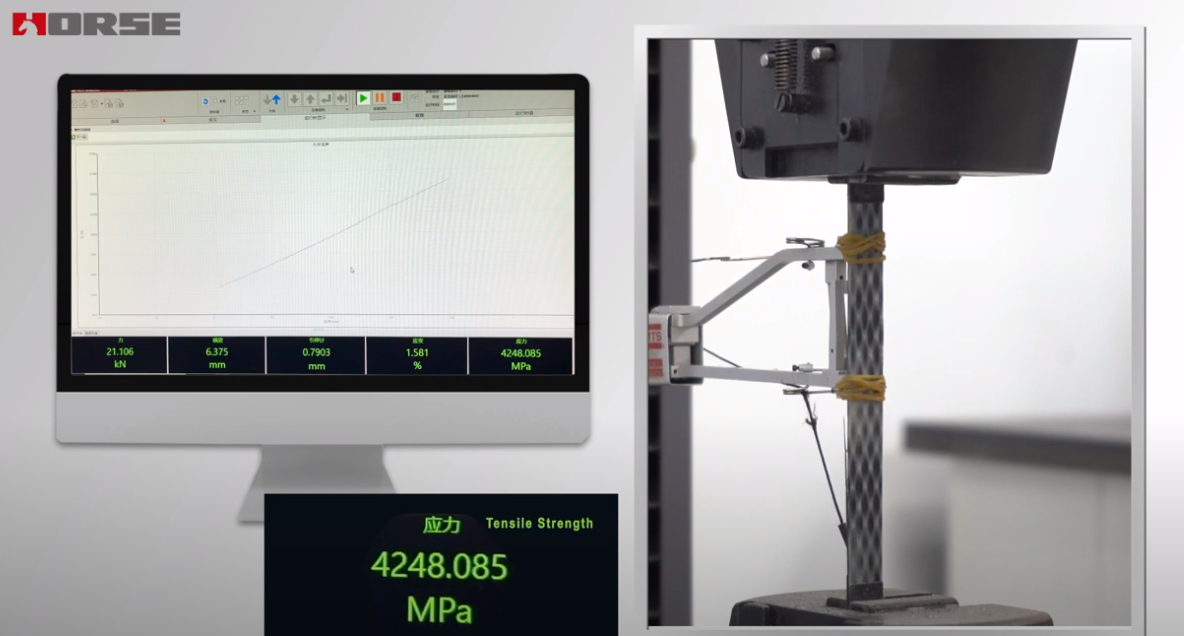

What is the tensile strength of carbon fiber cloth?

Indicates the maximum tensile strength that carbon fiber cloth can withstand per unit area.

How to calculate: The maximum force is divided by the original cross-sectional area of the specimen to obtain the tensile strength.

For example, for carbon fiber composite materials, the tensile strength of single-phase fabric (cloth) is 3400Mpa, which means: 1mm ² carbon fiber cloth with a cross-sectional area can withstand a force of 3400N.

Design value of tensile strength

The tensile strength of the same carbon cloth may vary among different reinforced components.

The design value of tensile strength of primary carbon cloth is taken as 1600MPa in important components and 2300MPa in general components.

Many people wonder why the more important the component, the smaller the design value?

The design value of tensile strength is calculated during force calculation.

The standard value of tensile strength for primary carbon cloth is 3400MPa, which is already determined. Therefore, the smaller the value in calculation, the safer it is. Therefore, the design value of tensile strength for important components is smaller than the design value of tensile strength for general components.

The design unit pays more attention to the design value of tensile strength, as the tensile strength design value is used in force calculation.

The relationship between the standard value of tensile strength and the design value

The standard value must reach 3400MPa before the design value can be calculated.

So how much will carbon fiber cloth reinforcement play? This really depends on the project situation. If the tensile strength exerted by carbon fiber cloth in this project is less than the design value, it is not suitable for carbon fiber cloth reinforcement.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.