Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Carbon Fiber Material Is Famous Again In The Winter Olympics!

The hot search has been dominated by the Winter Olympics in the past few days. First of all, I warmly congratulate the Chinese athletes for their excellent results, but the protagonists I want to share with you today are not them, but the carbon fiber material that has become popular in the Winter Olympics.

I believe that those who do reinforcement are familiar with carbon fiber materials. Carbon fiber cloth, carbon fiber board, carbon fiber mesh cloth, etc. are all popular reinforcement materials, which can be seen everywhere in major reinforcement projects. However, for the entire carbon fiber industry, the application in structural engineering is only the tip of the iceberg. Due to its excellent properties such as high strength, light weight and strong durability, it has also been widely used in other fields. The sports industry is one of them. Now let's take a look at how carbon fiber materials shine in the Beijing Winter Olympics.

There is a big universe hidden in the small torch

As one of the elements that have attracted much attention in the previous Olympic Games, the "Flying" Torch of the Winter Olympics attracted countless attention as soon as it was unveiled.

The torch casing must withstand the double test of "ice and fire". Not only fire-resistant and high-temperature resistant, but also able to be used in extremely cold weather.

The Winter Olympic torch "Flying" combines carbon fiber and high-performance resin to make a carbon fiber composite material. The density is only about 1/4 of that of steel, but the strength is 7 to 9 times that of steel. Through three-dimensional weaving of carbon fiber filaments, the torch shell is finally woven like a "knitting sweater", without any seams and pores, and the whole shape is integrated.

In order to achieve high temperature resistance, the combustion end of the upper half of the torch is ceramized at a high temperature above 1000 ℃, which effectively solves the problems of foaming and cracking of the torch shell during the high temperature preparation process. It meets the requirements of both temperature resistance and fire resistance, and realizes normal use in a hydrogen combustion environment with a combustion temperature of >800 °C.

And the torch made of carbon fiber is light and strong, and it will not break. At the same time, when the torch is passed in winter, traditional metal materials do not feel good. Carbon fiber can effectively solve this problem and avoid the cold touch.

Carbon fiber hydrogen energy products shine

In this Winter Olympics, carbon fiber hydrogen energy products shined brightly: hydrogen fuel cell vehicles equipped with hydrogen storage tanks successively served the two competition areas of Beijing Yanqing and Zhangjiakou in batches to help the 2022 Winter Olympics. The first batch of hydrogen energy commuter buses jointly developed by Yutong Group and State Power Investment Hydrogen Energy Company use 165L hydrogen storage cylinders, and the designed cruising range can reach 630 kilometers.

Hydrogen energy products not only serve the commuting field of the Winter Olympics, but also use 165L hydrogen storage tanks to provide logistics and transportation services inside and outside the competition area, while hydrogen fuel cell police patrol vehicles, fire patrol vehicles and postal vehicles use 53L hydrogen storage tanks . In the field of hydrogen fuel cell vehicles, the improvement of on-board hydrogen storage technology will be a key breakthrough in the development of hydrogen fuel cell vehicles in the future. In the entire on-board hydrogen supply system, hydrogen storage cylinders are one of the key components. Among them, carbon fiber wound composite hydrogen storage cylinders have high hopes.

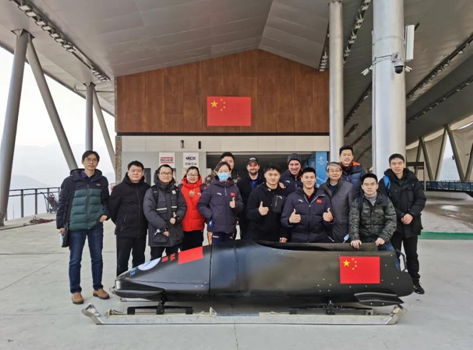

Domestic snowmobile equipment from "no" to "yes"

Snowmobiles are a traditional event in the Winter Olympics. Behind the snowmobiles is the hard power of China's Olympic scientific research. To this end, the Institute of Aerospace Materials and Technology has set up a special working group, and with the support of the Ministry of Science and Technology and the Winter Sports Center of the General Administration of Sports of the People's Republic of China, a research and development project of "Key Technologies for High Performance Equipment of Carbon Fiber Composite Materials in Winter Projects" has been established. It has broken through a series of key technologies such as the integrated design of the shape and structure with low wind resistance and high reliability, the high impact carbon/glass hybrid composite material, and the integrated high-quality molding of the complex wing-body fusion structure. Finally completed the design of the principle prototype of the first domestic double snowmobile, the development of special material system, product development and manufacturing.

At last year's China International Composites Industry Technology Exhibition, the Institute of Aerospace Materials and Technology brought the first-generation snowmobile to the innovative product exhibition area for display. The snowmobile weighs about 180 kilograms and is made of carbon fiber composite material + alloy material, which has achieved a breakthrough from "no" to "existent" domestic snowmobile equipment.

3D printed carbon fiber speed skates help the Winter Olympics

In order to change the situation that the world-renowned carbon fiber speed skating shoes are monopolized by European and American companies, Yang Jintian, a professor of sports biomechanics at Hebei University of Economics and Business, and his research team have established a database of speed skaters' foot shapes and soles, as well as a sole 3D scanning and printing system. . It took more than a year to successfully develop the first generation of high-performance carbon fiber composite speed skating shoes. Compared with China's high-end speed skating shoes, the weight of carbon fiber skates is reduced by 3%-4%, and the peel strength of the skates is increased by 7%.

Professor Yang Jintian said that the team will promote the iteration of skates and strive to enter the industrialization stage as soon as possible. He also announced that the second-generation domestic skates will be able to compete with similar foreign products, achieve "curve overtaking" of imported brands, and enhance "skills" for the development of ice and snow sports in my country.

Carbon fiber hockey sticks debut at the Winter Olympics

The carbon fiber ice hockey stick reduces the fluidity of the fluid molding agent to below the preset threshold and controls the quality error of the carbon fiber cloth within ±1g/㎡-1.5g/㎡ by mixing the fluid molding agent into the carbon fiber cloth. . The carbon fiber cue base made of carbon fiber cloth is put into the mold, the inflation pressure of the mold is controlled at 18000Kpa to 23000Ka, and the carbon fiber cue base is heated to form the ice hockey stick.

The fluid forming agent adheres to the surface of the carbon fiber cloth, which increases the toughness of the carbon fiber cloth on the one hand, and enhances the overall structural strength of the club on the other hand. Carbon fiber hockey sticks are not prone to cracking or breaking, ensuring that the hockey sticks are strong and durable.

Carbon fiber heating cable is warm

Walking into Zhangjiakou Winter Olympic Village (Winter Paralympic Village), the concept of green Olympics can be seen everywhere. In the athlete's apartment, the sun shines through the floor-to-ceiling windows, creating a warm feeling. According to reports, carbon fiber heating cables are laid under the floor of the athlete's apartment, and electric heating is used in winter, which directly converts electric energy into heat energy and reduces heat loss. All the electricity used comes from wind power generation in Zhangjiakou, which is clean, renewable, and environmentally friendly.

The staff of the Olympic Village Operation Department said that the Zhangjiakou Winter Olympic Village was constructed in accordance with China's highest green building three-star standard. By taking a series of land-saving, energy-saving, material-saving and water-saving measures, the Winter Olympic Village not only conforms to the concept of green Olympics, but also fully meets the needs of the Winter Olympics.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.