Repair And Reinforcement Of Xiliu Viaduct

Prestressed Carbon Plates

The bridge maintenance and reinforcement used new technologies and new materials such as prestressed carbon plates, external beam reinforcement, and high-strength steel wire cloth reinforcement.

Due to the gradual increase in traffic flow in recent years, the traffic pressure on the Xiliu Viaduct has also increased day by day. As time goes by, this weather-beaten elevated road has gradually become obsolete, and there are potential safety hazards. To this end, in December 2021, the city invested 180 million yuan to repair and reinforce the G20 Xiliu Viaduct. At present, various constructions have been fully launched and are scheduled to be completed by the end of this year.

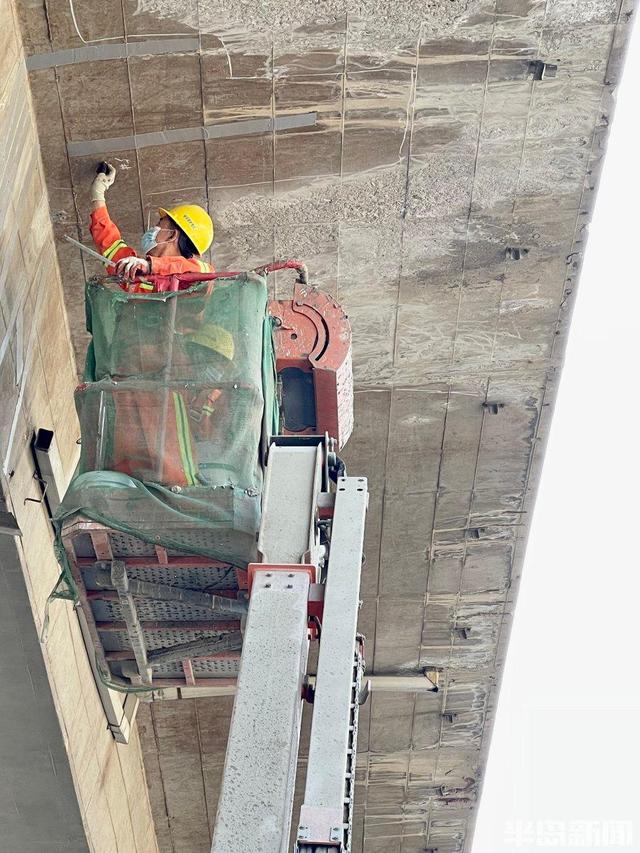

The construction area at the bottom of the Xiliu Viaduct has been fenced off, various large-scale machinery such as construction lifts have been put in place, and workers are carrying out maintenance and reinforcement operations for paving high-strength steel wire cloth.

It is understood that the starting point of the G20 Xiliu Viaduct is Xiyuanzhuang and the end point is Liuting. It is the open section of the G20 Qingyin Expressway, with a total length of 6850 meters and a width of 23 meters. It is a separate double-width bridge. The bridge maintenance and reinforcement used new technologies and new materials such as prestressed carbon plates, external beam reinforcement, and high-strength steel wire cloth reinforcement.

According to the on-site construction personnel, the main advantages of prestressed carbon fiber panels are strong tensile capacity and low self-weight, which can effectively improve the bearing capacity of the bridge. Combined with the construction of external prestressed beams, bridge diseases can be thoroughly and effectively dealt with.

The high-strength steel wire cloth used is a new material. It is light in weight, high in strength, and has excellent corrosion resistance and durability. It can greatly strengthen the beam and plate structure and improve the bearing capacity and durability of the bridge.

At the same time as the reinforcement work under the bridge, the lifting construction of the guardrail on the bridge is also being carried out simultaneously. After that, the pavement of the whole bridge will be paved and all expansion joints will be replaced. Due to the reasonable scientific flow adjustment measures taken in advance, the traffic on and under the bridge has not been greatly affected.