CFRP Sheet Reinforced

Reinforced Pressurized Tunnel Lining

The reinforcement project of the lower flat hole of the power generation diversion tunnel started in November 2015 and was completed in March 2016, with a construction period of 130 days. In short, this project adopts CFRP sheet as the main measure to reinforce the tunnel lining, and the effect is satisfactory.

Process overview

The total length of the water diversion pressure tunnel of Wujun Hydropower Station in Taihu County, Anhui Province is 7.76m. The total length of the Xiaping hole is 443.6m and the diameter of the hole is 2.0m. The pile number 7+337-7+643.25 is reinforced concrete lining, and the 7+643.25-7+722.45 is the steel plate lining section.

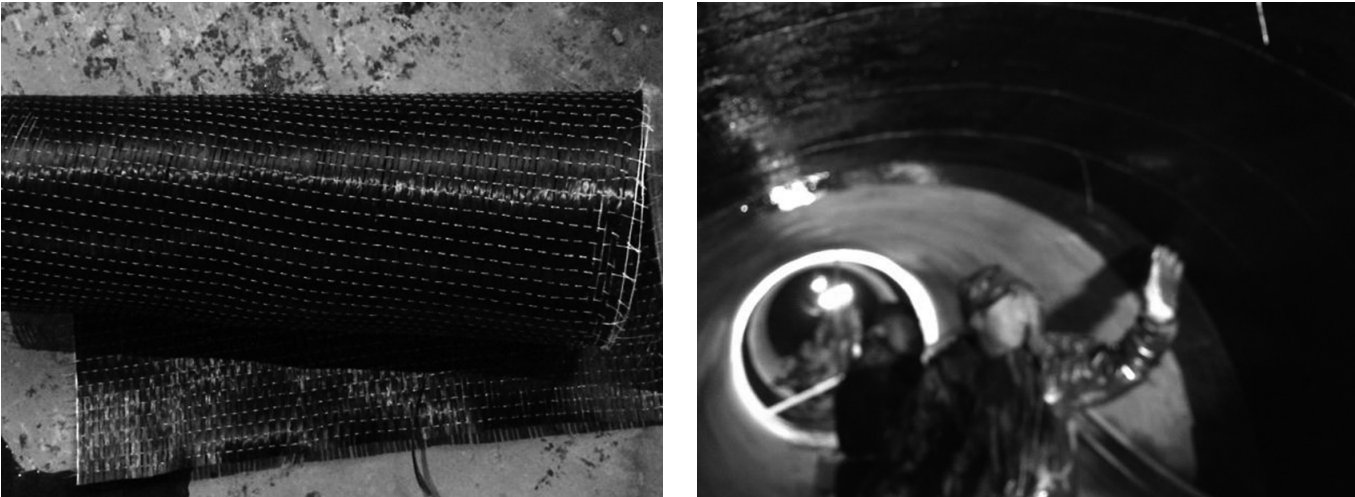

Cracks and water leakage in the lining of the flat tunnel under the tunnel

Since it was completed and put into operation in 2001, the leakage problem of the power generation diversion tunnel has continued. In 2000, there was water leakage at the exit of the tunnel, causing the slope behind the power plant to collapse, and the landslide body rushed into the plant. After grouting the mountain at the exit, the original leakage point is no longer leaking, and the water outlet is raised to about 180m at the half-slope elevation of the mountain, resulting in the collapse of the mountain slope on the left side of the tunnel near the Taibei Highway. In 2008, the construction support hole was opened, and it was found that the lining of the lower flat hole was generally cracked. The cracks were treated with rubber in that year, but the leakage problem was not effectively solved. At the end of 2014, the construction support hole was opened again, and it was found that the rubber part of the repaired lining of the lower flat hole was torn or broken again, and there were dripping and leaking phenomena, as shown in Figures 1 and 2.

Lining reinforcement scheme of flat hole under tunnel

General Handling

The appearance quality of the lining concrete of the lower flat hole is good, and the strength and thickness meet the original design requirements, but the inspection found that the quality of the backfill grouting is poor, except for the pile number 7+503.25, most of them are unqualified, especially the top arch. In order to improve the bearing capacity of the surrounding rock and strengthen the close combination of the lining and the surrounding rock, backfill grouting is carried out on the top of the 7+337-7+643.25 section of the Xiaping tunnel, and the surrounding rock is consolidated and grouted, with a total length of 306.25m.

After the tunnel grouting project is completed, the section of the tunnel wall shall be cleaned, the existing crack repair rubber shall be removed, and epoxy grouting + epoxy mortar shall be used for repair.

Structural reinforcement treatment

For the insufficient strength of the lining structure in the 7+563.85-7+643.25 section, consider the following four reinforcement schemes for comparison, see Table 2. After comparison, the reinforcement scheme of carbon fiber cloth is recommended.

The reinforcement range of carbon fiber cloth is the pile number 7+563.25-7+643.25 of the lower flat hole, and the total length is 80m. Among them, the 36m section of the pile number 7+607.25-7+643.25 is reinforced with double-layer cloth, and the remaining 44m is reinforced with single-layer cloth.

The carbon fiber cloth type is Ⅰ-300, the cloth thickness is 0.167mm, the tensile strength is required to be ≥3400MPa, the elastic modulus is ≥240GPa, and the elongation rate is ≥1.7%.

| Comparison | Demolition and reconstruction | Lined with reinforced concrete | Stick steel | Carbon fiber cloth reinforcement |

Structure and Practice | The existing lining is removed, and the 0.35m thick C25 reinforced concrete lining is used again, and the hole diameter D = 2m. | Without removing the existing lining, it is directly lined with 0.3m thick C25 reinforced concrete, and the hole diameter D = 1.4m. | The existing lining is not removed, and the steel plate is directly bonded, the thickness of the steel plate is 6mm, and the hole diameter D = 1.9m. | The existing lining is not removed, and carbon fiber cloth is used for reinforcement, and the hole diameter D = 2.0m. |

| Unit length | Reinforced concrete demolition 2. 8m3 | C25 reinforced concrete: 1. 60 m3 | ||

Main project quantity | Formwork: 12. 9 m2 Rebar: 0. 26t | Rebar: 0. 16t | Steel plate: 6. 0m2 | Carbon fiber cloth: 12. 56 m2 |

Appraisal/yuan·m - 1 | 5780 | 2920 | 7560 | 6780 |

| Advantages and disadvantages | The construction process is relatively simple; The current lining removal is difficult and the construction period is long; The project cost is high. | The construction process is relatively simple; Long construction period; Occupies a lot of water passing area of the tunnel, and the loss of power generation is relatively large; The project cost is low. | Occupy less water passage area of the tunnel; complex process; Long construction period; The project cost is high. | Occupy the tunnel water passage area is very small, the process is relatively simple; Short construction period; The project cost is relatively low. |

| Conclusion | can be used | should not be used | can be used | recommended |

Epilogue

Wujun Reservoir Power Generation Diversion Tunnel Xiaping Tunnel Reinforcement Project was started in November 2015 and completed in March 2016, with a construction period of 130 days. Since the reinforcement in 2016, the Xiaping tunnel has been operating normally, and no leaks or slumps have been found on the exit hillside. In short, this project adopts carbon fiber cloth as the main measure to reinforce the tunnel lining, and the effect is satisfactory.