Bridge Strengthening

Prestressed Carbon Fiber Strip

In the regular inspection of the bridge in 2018, it was found that the main existing diseases of the composite box girder of the Qiaoqi junction main line bridge were: horizontal cracks in the bottom plate, longitudinal cracks in the bottom plate, vertical cracks in the web, and longitudinal cracks in the web. According to the condition of the bridge, the prestressed carbon fiber strip reinforcement technology is used to reinforce the bridge.

Project Overview

Qiaoqi Hub is an important link between Beijing-Shanghai Expressway and Shanghai-Wuhan Expressway, and heavy-duty vehicles pass through all year round. The Qiaoqi junction main line bridge is 1,570.14m in length and 28m in width. It is composed of fabricated prestressed concrete continuous box girder, reinforced concrete continuous girder, and steel box girder. The entire bridge adopts bored pile foundations and column piers.

In the regular inspection of the bridge in 2018, it was found that the main existing diseases of the composite box girder of the Qiaoqi junction main line bridge were: horizontal cracks in the bottom plate, longitudinal cracks in the bottom plate, vertical cracks in the web, and longitudinal cracks in the web. According to the condition of the bridge, the prestressed carbon fiber strip reinforcement technology is used to reinforce the bridge.

Material selection

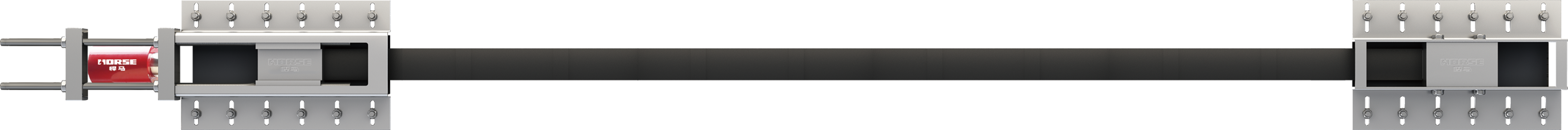

The prestressed carbon plate tensioning system used in this project is shown in Figure 1.

1 Limit frame selection

At present, the market upper limit frame is mostly welded structure, the material is Q235B, the tensile strength is 370MPa, and the yield strength is 235MPa. This kind of limit frame has disadvantages such as low welding structure stability, insufficient material stability, and easy deformation. Therefore, the limit frame selected for this project is a one-piece molding, made of 45 steel (steel with an average carbon content of 0.45%), with a tensile strength of 600 MPa and a yield strength of 355 MPa. The advantage is that the limit frame is a one-piece structure with good integrity and high carrying capacity; the limit frame material is more stable than market products.

2 Selection of anchor blocks

The anchor block plays an important role in the tensioning process of the carbon plate. The quality of the material is an important factor for the success of the carbon plate tensioning. The anchor blocks on the market are mostly cast iron, which has poor integrity and toughness. Therefore, the anchor block made of 40 chrome was selected for this project. The strength of the anchor block has been greatly improved, which also improves the success rate of carbon plate tensioning, and the anchor block uses the integrated molding technology of the machining center, which has better integrity and higher anchoring efficiency.

3 Selection of anchor clips

At present, the materials and shapes of anchor clamps on the market are different. Most of them are carbon semi-statically determinate structural steel (Q235B). The common splint shape is rectangular, and there is stress concentration at the corners. The disadvantage is that the material of the clip is not up to the requirements during the tensioning process, and it is easy to deform. The shape of the clip is rectangular, and the carbon plate is not uniformly stressed. . Therefore, the material of the clip selected for this project is 45 steel and the shape is oval. There is a bit of advantage: in terms of material, 45 steel has better compressive strength and better yield, and the shape of the clip is improved to an arc shape, so that the carbon plate is more evenly stressed during the carbon plate tensioning process and prevents the carbon plate from tensioning. The uneven force during the pulling process causes the carbon plate to break. The teeth of the clip are passivated to reduce the damage to the carbon plate without losing the bite force.

4 carbon plate selection

The quality of the carbon plate and the processing technology directly affect the quality of the carbon plate. The carbon filament content used in the production of the carbon plate is mostly 12K (the number of single filaments in the tow is 12,000). The creel carbon filament tension control is to ensure the strength of the carbon plate. The essential. The carbon plate used in this construction, the carbon wire is imported from imported materials, and a new equipment is introduced during the processing-a constant tension creel. Compared with the ordinary creel, it can ensure the uniform distribution of carbon wires and ensure the quality of the carbon plate.

5 Selection of adhesive

The carbon fiber strip structural glue adopts imported epoxy resin raw materials, a unique dual planetary power mixing system and an exclusive island toughening system to ensure the strength of the gel and long-term use performance. Tested by authoritative institutions, it is safe and non-toxic to ensure the safety of construction and use.