Renovation Project

CFRP Sheet

Due to the tight construction period, after comprehensively comparing various reinforcement schemes, all parties agree that the method of sticking carbon fiber sheet reinforcement is the most appropriate.

This case is a high-rise frame shear wall structure. The main structure of the building has been completed and it has begun to enter the stage of decoration and equipment installation. Due to the owner's request to change the location of the equipment, the equipment load will increase on the top of the building. For this reason, the original top structure must be reinforced. Due to the tight construction period, after comprehensively comparing various reinforcement schemes, all parties agree that the method of sticking carbon fiber sheet reinforcement is the most appropriate.

SLAB

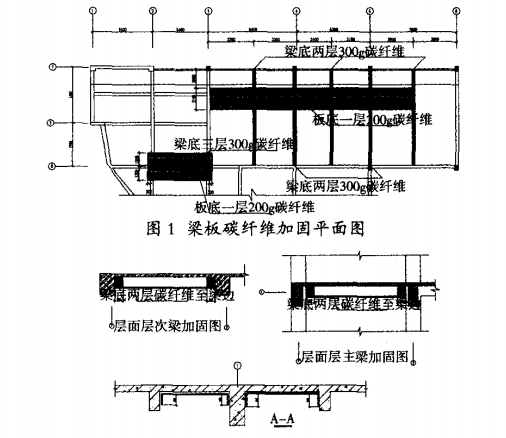

Through analysis, the initial bending moment in the slab exceeds 20% of the bending bearing capacity of the unreinforced section, and the influence of the secondary force needs to be considered

BEAM

According to the review, the shear capacity of the beam meets the requirements, and only the bending reinforcement design is required. Moreover, the initial bending moment of the beam under the existing load is less than 20% of the flexural bearing capacity of the unreinforced section, so the influence of the secondary force is not considered. After considering the increased load, the amount of carbon fiber required can be calculated directly according to the design method of reinforced concrete beams, and then replaced according to the principle of equal strength substitution.

The quality of on-site construction is the key to the full effect of reinforcement. The carbon fiber sheet reinforced base surface of this project is fresh concrete with a strength grade of C30 and an ambient temperature of 10-20°C, which can fully meet the construction requirements. The carbon fiber sheet paste construction process is to polish the surface of the concrete first, and then apply a layer of primer after it is leveled and cleaned. Fill the cavity with leveling material, and then apply impregnating resin to paste carbon fiber. Roll it repeatedly with a roller to remove air bubbles, fully soak the carbon fiber sheet, and finally remove another layer on the surface of the carbon fiber sheet. If there is a hollow part, the impregnating resin can be injected with a needle tube. In particular, it should be pointed out that if the effective bonding area is less than 95%, the original bonding shall be judged to be invalid and re-construction shall be required. At the same time, in order to ensure the normal use of the reinforced components and avoid the aging of the carbon fiber sheet and other damages, the outer surface of the carbon fiber sheet reinforcement layer must be sealed and protected. The airtight protective layer can be made of high-grade cement mortar mixed with cementing agent as the airtight protective layer. First, brush a layer of interface treatment agent on the outer surface of the carbon fiber sheet reinforcement layer, and then cover the cement mortar. Its thickness should not be less than 20mm. At the same time, after pasting the carbon fiber sheet, take immediate protective measures to avoid external impact loads.

The use of carbon fiber sheet reinforcement can effectively transmit the new load, and due to the simple material procurement and construction, better economic benefits can be achieved.