Seismic Reinforcement of a Public Building

Carbon Fiber Material

The main structure reinforcement of this project has been completed. The carbon fiber bonding amount is 300 square meters, and the entire construction period is 20 days. The construction period is guaranteed, the reinforcement quality has also been well guaranteed, and a good comprehensive benefit has been received.

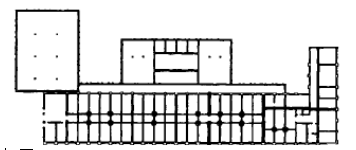

The public building functions as a teaching building. It was built in 1960. The main body is a 4-story double-row column inner frame structure. The inner frame column adopts an independent foundation. The buried depth of the foundation is -3.2m, the building height is 20.4m, and the local area is 4-story brickwork. The physical structure, the building area is 8267 square meters, and the plan layout is shown in Figure 1. Due to the earlier construction time of the building, seismic fortification was not considered in the design. The end stirrups of the beams and columns in the inner frame node area are not densified, so that the building has sufficient seismic capacity. According to the "Building Seismic Appraisal Standard" (GB0023-95), the seismic appraisal of the building was carried out. The conclusion showed that the inner frame beam-column node area must be seismically strengthened because the stirrup diameter and spacing do not meet the requirements.

Determination of seismic reinforcement plan

The beam-column node area of the frame structure is complicated due to the force. In order to ensure the design principle of "strong nodes and weak members" in the code, the principle of hooping reinforcement in certain areas of column and beam ends is usually adopted to prevent brittle failure in the node area and enhance the seismic performance of the structure. Due to the requirements of construction period, capital and building function, this project puts forward many restrictions on the reinforcement plan, and the traditional seismic reinforcement plan is difficult to implement. On this basis, we formulate various reasonable plans and compare the advantages and disadvantages of each plan to determine the best plan.

Option 1-Bonded Steel Reinforcement Method

The bonding steel reinforcement method is a traditional reinforcement method commonly used in China. However, it is easy to rust at the interface between the adhesive glue and the steel plate, which weakens the bonding strength and affects the reinforcement effect.

Option 2-Bonded Carbon Fiber Reinforcement Method

Compared with traditional reinforcement methods, this technology has many obvious advantages, such as high strength and high efficiency, convenient construction, wide application range, and good material durability. Due to the high requirements for reinforcement technology in this project, traditional reinforcement methods are difficult to work. Carbon fiber reinforcement is more suitable because it requires fewer equipment and tools, does not produce open flames, does not change the size of the original structure, does not increase the load of the original structure, and has less construction impact. The comparison of the schemes is shown in Table 1. It can be seen that scheme 2 is a more suitable reinforcement method for this project.

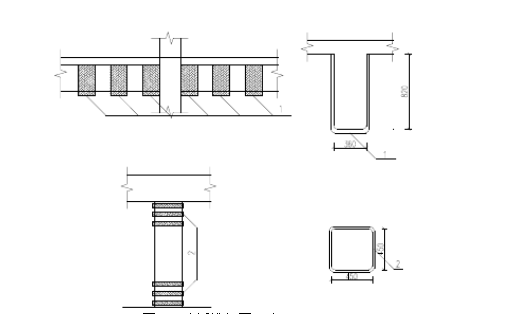

In the reinforcement design, on the basis of the original stirrups of the concrete beams and columns, carbon fiber is pasted along the U-shape or circumferential direction perpendicular to the axial direction of the member. The total converted hoop feature rate meets the requirements of the corresponding specifications, and the seismic performance of the joint area is significantly enhanced.

The main structure reinforcement of this project has been completed. The carbon fiber bonding amount is 300 square meters, and the entire construction period is 20 days. The construction period is guaranteed, the reinforcement quality has also been well guaranteed, and a good comprehensive benefit has been received.