Huarun Hotel

Renovation and Seismic Reinforcement

Seismic reinforcement of existing buildings is no longer a single structural professional issue, but more attention should be paid to the combination of green environmental protection, improving building functions and quality, and increasing economic benefits under the premise of ensuring structural safety.

Project

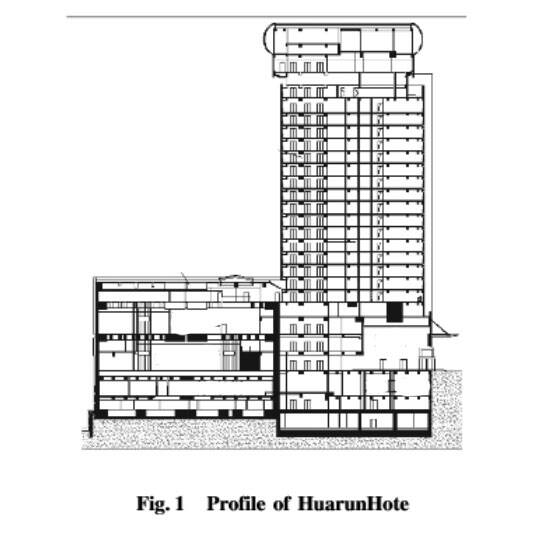

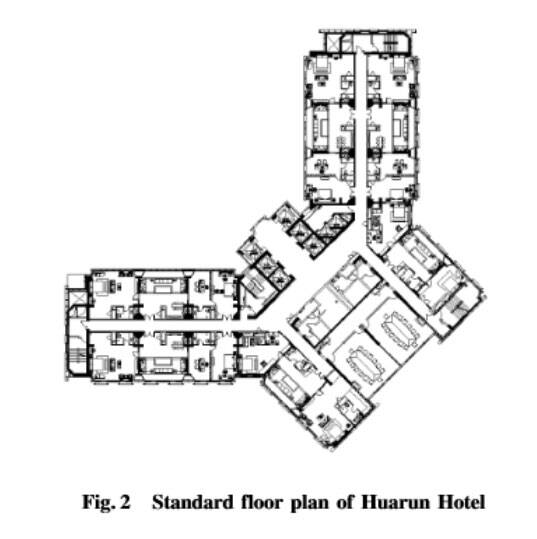

China Resources Hotel is located at No. 35 Jianguo Road, Chaoyang District, Beijing, with a total construction area of 62281.8 m2, of which 50,963 m2 is above ground. The height of the main building is 76.25m, with 25 floors above ground and 3 floors underground; the podium has 5 floors above ground and 2 floors underground (see Figure 1 and Figure 2).

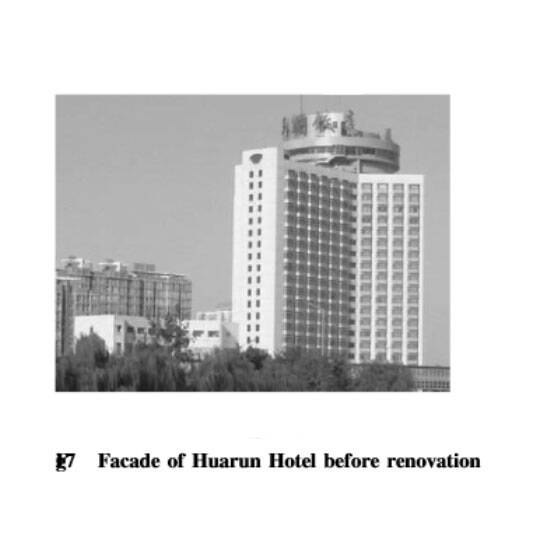

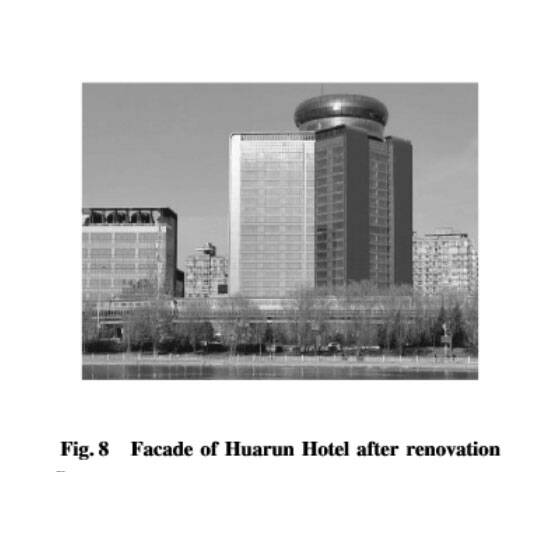

After the changes over the years, the China Resources Hotel has successfully completed its mission of more than 20 years after the 2008 Beijing Olympics. Its architectural appearance, interior decoration and mechanical and electrical equipment are all outdated. In order to adapt to the development of the new era, it urgently needs to be upgraded and updated, so as to rejuvenate its business vitality and space-carrying charm.

Problems

China Resources Hotel changed from a hotel to an office, and there were major problems in the majors of architecture, structure, water supply and drainage, HVAC, and electrical. For example, the low floor height, the shear wall structure can not realize the open office, the side air air conditioning system, the lack of intelligence of the building, the messy circulation of the main building and the podium, and the low utilization rate are not in line with the standards of modern office buildings. In particular, the structural safety issues cannot be ignored.

On the one hand, due to the changes of the times and the improvement of seismic fortification standards, various structural incompatibility may be caused. On the other hand, functional changes, layout adjustments, and equipment additions in the transformation will also cause conflicts between existing structures and safety requirements. To make the reconstruction project economical and reasonable, but also to ensure the safety of life and assets, it must be ensured through structural inspection, seismic appraisal, reinforcement design and optimization, and the implementation of appropriate structural technical means.

On-site structure inspection report shows that:

(1) The current state of the building meets the requirements of the completed drawings, and no cracks or inclination due to foundation settlement or uneven settlement have been found, and no abnormal foundation deformation has been seen.

(2) Although the carbonization depth of some concrete components has reached the surface of the steel bar, except for a few cases of floating rust on the internal steel bar due to the loose concrete on the surface of the component, no durability limit state signs such as severe corrosion of the steel bar and surface concrete cracking and peeling were found in the structure. , The content of chloride ion in the concrete meets the specification limit.

(3) The strength of concrete, the strength of steel bars, the configuration of steel bars, the thickness of the protective layer, and the cross-sectional dimensions are all in line with the original design requirements.

Structural seismic appraisal

When appraisal is carried out according to Type B reinforced concrete houses, the main conclusions of the comprehensive evaluation of the seismic capacity of the houses are as follows:

(1) In terms of structural system rules, the size of the tower's plane unevenness is large, which does not meet the requirements of plane regularity; the tower is converted at four floors and does not meet the requirements of continuity of vertical members. The frame-supported layer has local floor offset large openings and cross-layer columns, and the number of landing shear walls at the corresponding position is small and local is weak.

(2) The structure of some frame beams and frame pillars does not meet the requirements.

(3) The axial compression ratio of the eight frame pillars in the key parts of the atrium does not meet the requirements, and the volumetric ratio of all frame pillars does not meet the specification requirements.

(4) The reinforcement ratio of the horizontally distributed steel bars of all floor-to-ceiling shear walls and the upper layer of the transition layer does not meet the requirements of the minimum reinforcement ratio of the specification.

(5) Taking into account the adverse effects of the existing seismic measures of the house, the comprehensive seismic capacity of the building is evaluated through the system influence coefficient and the structural influence coefficient. The comprehensive seismic resistance index of each floor of the building is greater than 1.0, indicating that the existing seismic resistance of each floor The bearing capacity is high. However, the results of the verification and analysis of the seismic measures show that due to the irregularity of the structural system, the houses have relatively concentrated weak areas, which are concentrated in the tower frame support parts, and overall reinforcement measures need to be taken for these parts. In order to reduce the irregularity of the system, enhance the seismic performance of weak parts.

Structural reinforcement

1) Change the structural system

Through seismic appraisal and the research and analysis of over-limit items, the core issue of this project is the "high-level conversion" caused by the frame-supported shear wall. If the structural system does not change, and only adopting the component reinforcement method of "treating the head and feet" will not be able to fundamentally solve the various problems that are disadvantageous to earthquake resistance. In addition, there are many reinforcement components, high engineering costs, and poor economic benefits. After full communication and close cooperation between the project team and the design unit, comprehensive evaluation from multiple dimensions of the building's use function, cost, feasibility, and construction period, finally determined the implementation plan of the frame-supported shear wall. The building structure is composed of a complex structural system. Change to ordinary shear wall system. As a result, irregular problems such as sudden changes in bearing capacity, sudden changes in stiffness, and discontinuities in components caused by frame supports will be effectively resolved. At the same time, the seismic level of the bottom floors has been reduced from one to two. The problems of insufficient bearing capacity of most structural members and unsatisfactory structural requirements have also been solved. The greatly reduced number of reinforcement members reduces the project cost and has good economic benefits.

2) The dry work reinforcement plan was changed to the wet work reinforcement plan

A reasonable reinforcement plan should meet the following requirements: good reinforcement effect, little impact on use functions, reliable technology, simple construction, economical and reasonable, and neat appearance.

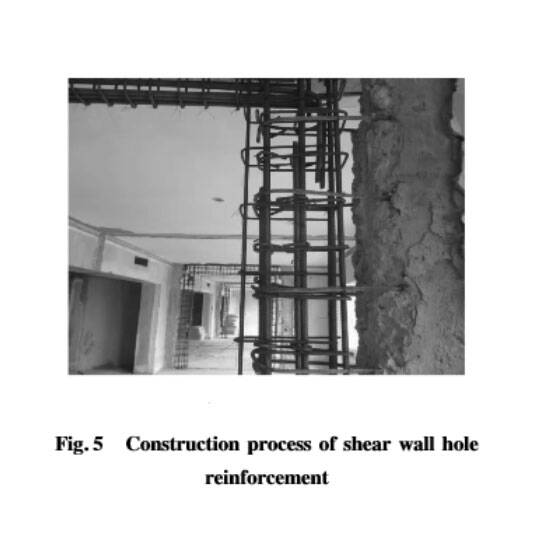

Due to structural safety requirements in this project, many beams and columns need to be reinforced. At the same time, in order to achieve the architectural function of a large open office and adapt to the adjustment of toilets and equipment tube wells caused by functional changes, a large number of original shear walls and floor slabs need to be partially opened.

The initial reinforcement plan mainly adopts dry operation methods: the newly opened openings are reinforced with pasted steel plates or pasted carbon fiber composites; beams and columns are reinforced with externally bonded steel (clad steel method). This reinforcement scheme uses a large amount of steel, requires a large amount of structural glue and chemical anchors, and has poor environmental protection performance and high cost. In addition, the thickening of the steel plate and the exposure of the anchors locally affect the function and look of the building.

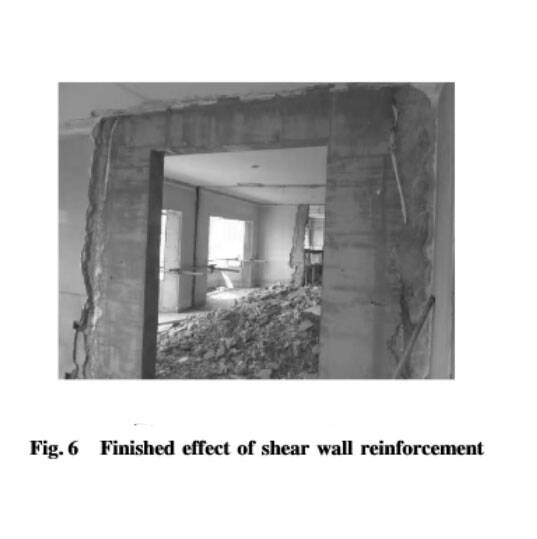

In view of the actual situation that the decoration layer of this project is completely demolished and the construction operation space is large, the original reinforcement plan was optimized after multiple evaluations and demonstrations. The concealed columns and connecting beams at the edge of the new opening of the shear wall are reinforced with planting bars and grouting. The large holes on the floor are reinforced with reinforced concrete side beams. After picking out beams and columns with insufficient bearing capacity, the enlarged section method is used to strengthen. The openings of the concrete components are all wet operation methods such as hydro-drill static excision. Compared with the original reinforcement scheme, the project cost is reduced by about 30%, the construction period is saved by about 60 days, and the impact on the building function and interior design effect is small.

Structural reinforcement engineering effect

The transformed China Resources Hotel was renamed as China Resources Chang'an Center, with a stable, simple and atmospheric appearance, which fully reflects the image characteristics of a modern office building (see Figure 7 and Figure 8). The internal space has also been renewed. Through the interior decoration design, the impact of the floor shear wall between the frame and pillars on the lobby space is weakened (see Figure 9 and Figure 10). Wet work reinforcement methods such as grouting material and fine stone concrete are used. After opening the door opening behind the shear wall and strengthening the beams, slabs and columns, the appearance is exactly the same as the appearance of the newly built concrete structure, which maximizes the use of the building and the smooth and beautiful effect.

Conclusion

Seismic reinforcement of existing buildings is no longer a single structural professional issue, but more attention should be paid to the combination of green environmental protection, improving building functions and quality, and increasing economic benefits under the premise of ensuring structural safety.