Bridge Maintenance and Reinforcement

Highway Srengthening with Carbon Fiber and Crack Injection

Combining the damage of the bridge and adopting various reinforcement measures can effectively save costs, extend the service life of the bridge, and improve the safety of bridge operations.

1 Reasons for bridge maintenance and reinforcement in the highway widening project

In the actual construction of the highway widening project, the damage caused by the soft soil foundation to the bridge is one of the main reasons for the need to repair and strengthen the bridge. Affected by the characteristics of soft soil embankments, their stability is generally poor. And after a long period of service, repeated loads, especially over-heavy loads of vehicles, will be harmed by harmful settlements. Eventually, some components of the bridge were damaged, which had a serious impact on the service life of the bridge. In general, for highway widening projects on deep soft soil foundations, it is necessary to consider the harm caused by uneven and harmful settlement to new and old bridges in the specific construction process. This is also the main reason for bridge maintenance and reinforcement:

① After the splicing of the old and new bridges is completed, the generated load will increase the settlement. That is, there will be a certain difference in settlement between the splicing part and the central separation zone of the original bridge. This settlement will break the originally stable bridge system, causing the entire bridge to continue to settle. Coupled with the repeated action of the load of passing vehicles, it will accelerate the generation of this differential settlement and produce small cracks in the splicing part. As time goes by, this kind of crack gradually expands and eventually forms a more serious crack, which has a serious impact on the safety of vehicle driving. Therefore, it is necessary to repair and strengthen the bridge, try to eliminate the impact of this differential settlement, effectively protect the driving safety of vehicles, and extend the service life of the bridge.

② If the foundation is soft during the embankment splicing, it needs to be pumped and dredged. This will inevitably cause the water level around the bridge foundation to drop. Because the bridge foundation itself has good water permeability, the change of water level will cause seepage from the inside to the outside, which will change the friction resistance of the base soil layer and make the splicing foundation unstable.

③From the perspective of the old bridge itself, since it has been in service for a long time, it has long been scarred under repeated vehicle loads. Therefore, in order to ensure the safety of vehicles, it is necessary to carry out bridge reinforcement and maintenance. In order to extend the service life of the old bridge, it can play a better value and economic benefits.

2 Bridge maintenance and reinforcement construction technology for highway widening project

2.1 Crack repair process Closed repair method.

That is to say, for the cracks generated at the bridge joints, if the cracks are small, generally within 0.1mm, the closed reinforcement method can be used. With the help of epoxy resin, after the bridge deck is cleaned, the cracks can be sealed by painting directly to prevent the cracks from expanding further.

2.2 Carbon fiber structural reinforcement

The following tools are used in this method: plastic cylinders, scrapers, angle grinders, agitators, electronic platform scales, special rollers, etc. The materials are carbon fiber cloth that meets national standards and qualified bonding materials.

The concrete reinforcement construction process is as follows:

First, you need to do a good job of substrate treatment. The concrete reinforcement part of the target bridge should be polished and leveled to ensure that it is clean and tidy, kept dry, and ensure that fresh concrete is exposed. The corners of the concrete should be polished carefully to keep it in an arc shape.

Then carry out primer treatment. Before applying primer, the repaired area should be accurately measured to determine the specific amount of primer. Put the main binder and curing agent in the container, and then use a mixer for mixing. After the mixing is uniform, apply it to the surface of the concrete to be reinforced to ensure that the coating is even and there is no damage or omission.

Then focus on damaged and height differences. Use leveling glue for leveling, and after the glue has set naturally, polish it smoothly with sandpaper.

Finally, the carbon fiber cloth is pasted. First, the stakeout should be done according to the design requirements and the actual situation. Then the carbon fiber cloth is cut and numbered, based on the standard amount of adhesive glue, combined with the temperature and humidity of the site, and calculate the amount of glue used and ensure that the glue is used up at once.

After the glue is applied, the carbon fiber cloth can be pasted, and the roller is used to roll along the direction of the sticking, so that the glue and the carbon fiber cloth are fully combined, and the sticking is more firm and reliable.

2.3 Reinforce the thin-walled abutment

For thin-walled abutments on deep soft soil foundations, vertical cracks generally occur. For the reinforcement of the abutments, unequal angle steel is generally used to increase the cross-section of the bridge deck. Maintenance and reinforcement.

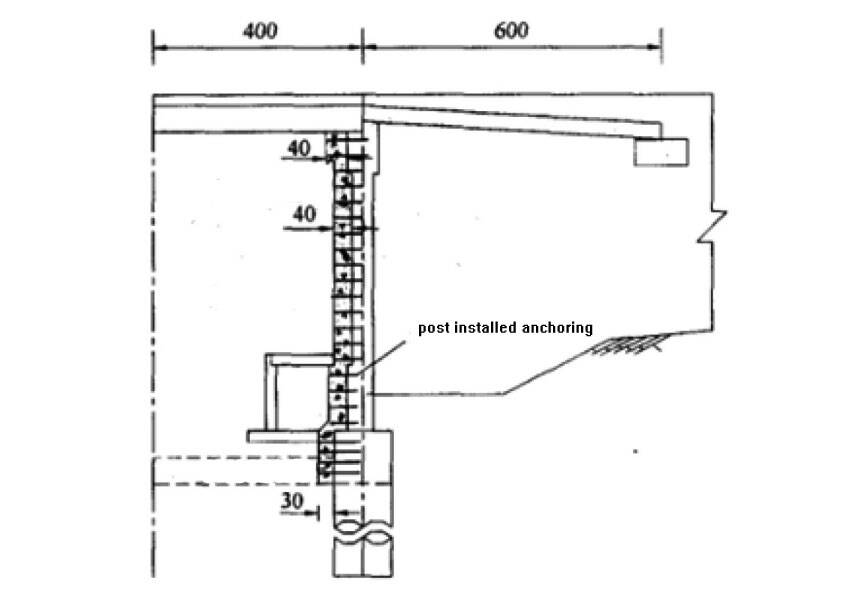

Specifically, firstly, gouging around the cross-section that needs to be enlarged, and after the fresh concrete is exposed, do a reinforcement loft and smooth the concrete at the sticking place. Then use the detector to detect the specific position of the steel bars on the table body, and drill holes on the table body in strict accordance with the design requirements. After the hole cleaning is completed, the planting glue is injected and the chemical bolts are placed in the holes and fixed. Then combine the hole conditions and drill holes on the unequal angle steel. It should be noted that the hole position on the angle steel is consistent with the hole position on the table body in the previous process, and the unequal angle steel is welded with the connecting steel bars. Apply epoxy mortar on the concrete contact surface and the unequal angle steel, and fix the unequal angle steel on the platform with chemical bolts. Finally, in the part where the unequal angle steel is not fixed on the table body, rebar should be planted. Pay attention to controlling the diameter of the steel bars according to the actual situation. Generally, the planting steel bars of φ25 and φ12 are mostly used. Then, the planted steel bars, the connecting steel bars welded by the unequal angle steel and the newly spliced bridge abutment steel bars are bundled into a whole, and the formwork is set up around it, and then the concrete is poured. Generally speaking, in the choice of concrete, 30# polypropylene fiber concrete is usually selected and the subsequent curing of the concrete is done. Finally, the subsequent construction of splicing new and old abutments is carried out. Generally, after the concrete reaches the design strength, the pavement and drainage ditch under the bridge will be restored. The specific diagram of the reinforcement of the thin-wall abutment is shown in Figure 1.

3 Conclusion

In summary, bridge maintenance and reinforcement is one of the important components of highway widening engineering construction. In the actual repair and reinforcement process, various reinforcement measures can be taken in combination with the damage of the bridge, which can effectively save costs, extend the service life of the bridge, and improve the safety of bridge operation. Therefore, relevant staff need to increase the importance of bridge reinforcement and maintenance, so that the construction quality of highway widening projects can be effectively improved.