Carbon Fiber Concrete Crack Repair

Beam Crack

According to the size and development of the cracks, the designer suggested that the owner adopt carbon fiber reinforcement for some beams of this building to enhance the shear strength of the frame beams.

The comprehensive office building was completed in 1997. During the quality inspection in August 2006, it was found that there were obvious oblique cracks at the ends of the beams of some frames, causing potential safety hazards. According to the size and development of the cracks, the designer suggested that the owner adopt carbon fiber reinforcement for some beams of this building to enhance the shear strength of the frame beams.

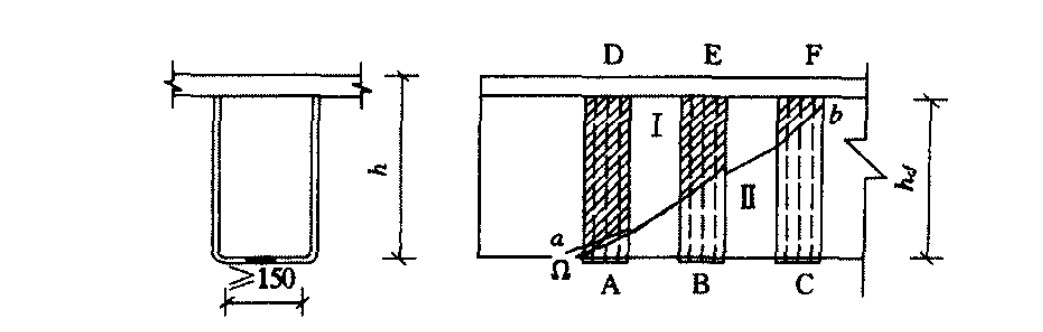

Its performance indicators are: single fiber direction, unit mass 200g/m2, thickness 0.111mm, tensile strength 3550MPa, elastic modulus 2.35×105MPa. The performance indicators of the adhesive for carbon fiber are: tensile strength 30MPa, shear strength 10MPa, bonding strength 2.0MPa, applicable temperature 5~35℃, and usable time 20~120min. The beam reinforcement scheme is shown in Figure . After carbon fiber reinforcement, the shear capacity of the beam is increased by 43%~62%.

Basic guiding ideas of carbon fiber cloth reinforcement design

(1) For components with good appearance, less corrosion of steel bars, and the concrete protective layer that has not yet cracked, that is, slightly corroded reinforced concrete structures, when calculating the bearing capacity, the self-strength of steel bars and concrete can be considered as the bond strength between them Nothing has been reduced. Therefore, for such components, if carbon fiber reinforcement is used, only preventive anti-corrosion reinforcement can improve the corrosion resistance of the component under adverse environments. This type of reinforcement is structural reinforcement, and it is not necessary to calculate the required amount of carbon fiber cloth.

(2) For severely corroded reinforced concrete structures where the concrete protective layer has cracked, the corrosion of the steel bars causes the reduction of the cross-sectional area of the steel bars, the strength of the steel bars, and the loss of the bond between the steel bars and the concrete. When carrying out carbon fiber reinforcement, the required number of longitudinal carbon fiber cloths should be calculated according to the different degrees of structural corrosion to improve the bending resistance. Calculate the number of transverse carbon fiber cloth to improve the shear capacity. Here, it needs to be pointed out that structural reinforcement is to restore and improve the strength of the entire component, not to compensate for the loss of steel.

Carbon fiber cloth dosage

According to the principle of equal force, the area of carbon fiber cloth can be converted into the equivalent steel bar area, namely:

The cross-sectional area of the CFRP cloth is multiplied by the allowable tensile stress of the CFRP cloth and divided by the tensile strength of the steel bar.

The area of the CFRP cloth is taken as its net area, that is, the calculated thickness of the carbon fiber cloth is multiplied by the width of the carbon fiber, and then multiplied by the number of layers of the carbon fiber cloth.

Anchor length

The bonding performance between CFRP cloth and concrete, no matter from the variable distribution or the stress distribution, there is an effective anchoring length. It can be seen from the graph of the distance between strain and crack that, except for the difference in value, the shape of the curve is very similar, indicating that the strain and stress in the carbon fiber cloth are developing steadily. At the same time, the bonding strain and stress mainly change significantly within 50mm from the crack, which can explain that the bonding and anchoring length of carbon fiber cloth is about 100mm.

In the half-century since CFRP came out, it has been widely used in many fields because of its physical, mechanical and chemical properties that traditional materials can't match, coupled with the availability of raw materials, and its price has gradually approached traditional materials.