Carbon Fiber Reinforced Concrete Cracks

Carbon Fiber Reinforced Concrete Cracks In Industrial Workshops

The use of carbon fiber cloth for crack reinforcement is a new type structural reinforcement method. Because of its simple construction, good corrosion resistance and fatigue resistance, it can be suitable for various shapes of reinforced structures. It has many advantages, such as high strength, no increase in structural weight, and no occupation of space.

Project Overview

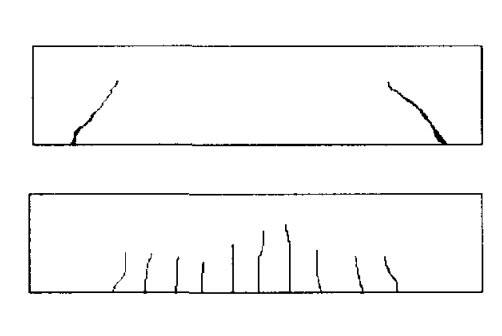

A two-story light industrial factory building has a beam-column structure on the ground floor, with a main beam span of 9m and a beam spacing of 6m. The upper floor is a brick-concrete structure. The main beam adopts on-site prefabricated reinforced concrete beam, and the top end is welded with the embedded steel plate on the side of the column through embedded parts. The floor is made of prefabricated reinforced concrete floor. During use, it was found that two of the girder surfaces had penetrating diagonal cracks near the two ends of the girder. The maximum width of the crack is 5mm, and the length ranges from 20 to 200mm, as shown in Figure 1.

Damage analysis

1 Judgment of the failure mode From the surface, the failure mode of the main beam of the structure is very similar to the shear failure. The preliminary judgment is the shear failure caused by the insufficient shear capacity of the beam. Considering that the plastering of the beam surface may have an adverse effect on the analysis and judgment, it is decided to conduct further inspection and analysis after the plastering is removed. When the plaster was removed, no cracking was found at the end of the beam. Several tiny cracks were found in the beam near the mid-span, the direction was perpendicular to the beam axis, the spacing was even, and the length of the cracks was about 1/3 to 1/2 of the beam height. According to the cracking of the beam, it can be basically concluded that the beam is damaged due to insufficient flexural capacity, and the possibility of damage due to insufficient shear capacity is ruled out.

2. Analysis of the cause of damage

Due to the lack of construction drawings of the original structure, it brought certain difficulties to the determination of the cause of structural damage. After on-site investigation, there were illegal operations in the construction of the main beam, and the field workers reported that the beam did not meet the specified maintenance time and carried out lifting construction. According to the damage of the beam and the large deflection, the lack of concrete strength may be one of the reasons for the failure of cattle production. After careful site investigation, it was found that the two-story brick wall was directly built on the reinforced concrete floor. This load does not exist in the original structure design. Due to the artificial change of the structural load, the actual structural force is inconsistent with the design load.

After carbonization test of concrete, no abnormal situation was found. Considering that the strength of concrete may be a factor of damage, the combination of ultrasonic and rebound is used to test the strength of concrete. After conversion according to the method specified in the specification, the cubic compressive strength of the concrete obtained meets the requirements of the original design C25.

According to on-site investigation results and experimental data analysis, the main reasons for structural damage are as follows: (1) The artificial change of the structure's use results in a large discrepancy between the actual load and the design load; (2) The simplified calculation model of the structure during design Treated with fixed beams at both ends, resulting in insufficient cross-section bending steel reinforcement configuration.

Beam structure reinforcement method

Considering that the factory building is in use and the internal space is limited, it is not suitable to use the method of increasing the cross-sectional size with a long construction period. There are flammable materials in the factory building, so welding equipment is not suitable. Based on the advantages and disadvantages of the above methods, it was decided to use unidirectional carbon fiber cloth to strengthen the damaged beam.

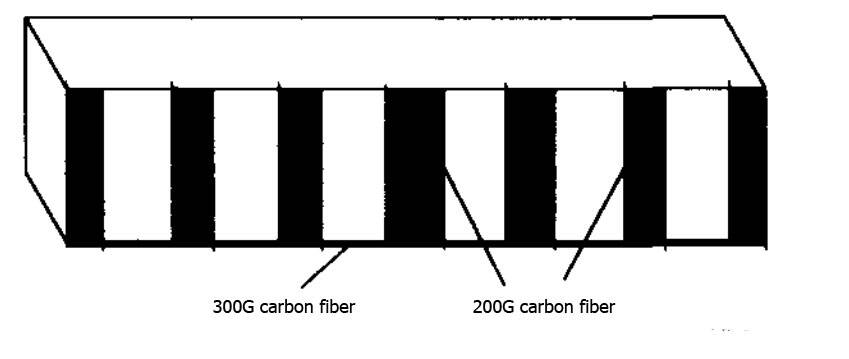

Among them, 300g carbon fiber cloth is used for bending resistance, and its function is equivalent to the longitudinal steel bars in reinforced concrete. The 200g carbon fiber cloth is used to constrain the 300g carbon fiber cloth, and at the same time, it has a certain shear resistance to ensure that the shear failure of the structure under the accidental load will not occur before the bending failure.

In conclusion

The use of carbon fiber cloth for structural reinforcement is a new type of structural reinforcement method. Because of its simple construction, good corrosion resistance and fatigue resistance, it can be suitable for various shapes of reinforced structures. It has many advantages, such as high strength, no increase in structural weight, and no occupation of space. It is a new type of building material that can be vigorously promoted in structural reinforcement and reconstruction of existing buildings.