Reinforced Damaged Flue

Carbon Fiber Fabric

Through the inspection and appraisal of the structure of the flue of the thermal power plant, it was concluded that it must be reinforced, and it was determined that it should be reinforced with pasted carbon fiber. The practice proved that the reinforcement effect is good, pointing out that the carbon fiber reinforcement technology has a wide range of promotion and application value.

Overview

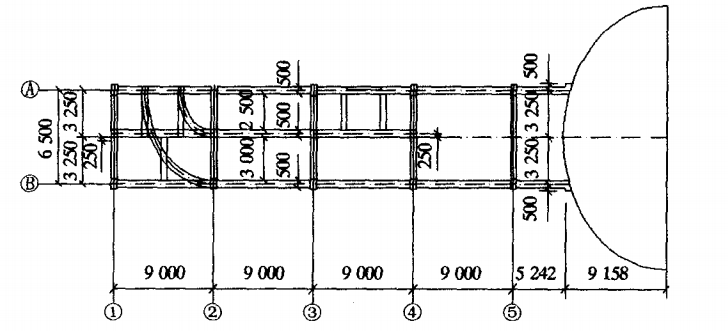

In order to implement the national policy, a thermal power plant carried out desulfurization technology transformation on the generating unit. Among them, the flue structure needs to be modified and desulfurization facilities added. The flue was built in 1985. The lower part is a supporting structure in the form of a reinforced concrete frame, and the upper part is a reinforced concrete box-shaped flue with a rectangular section. The elevation of the top of the flue is 13.35m, and the elevation of the top of the support is 6.53m. The main girder of the support frame is divided into five spans, and the span is 9m except for the axis ⑤-chimney body which is 4.85m. The plan view of the flue is shown in Figure 1. After more than 20 years of operation, the flue has experienced serious damage, such as concrete cracking, looseness and spalling, exposed steel bars, and corrosion. In order to ensure the safety of the entire technological transformation project, the structural safety of the flue must be ensured. First, conduct a comprehensive inspection and identification of the structure, and evaluate its safety status. According to the specific situation, adopt appropriate schemes to strengthen and protect the structure to ensure that the structure can continue to operate safely.

Test conclusion

1) According to the test results, in accordance with the GBJ144-90 Industrial Plant Reliability Appraisal Standard, the safety level of the flue structure is rated as level three; the usability level is level three.

2) The condition of the flue structure is not safe enough under the current state of use, but there is still value for reinforcement. After taking appropriate reinforcement measures, it can continue to be used safely for a certain number of years.

Structural reinforcement method scheme

Structural reinforcement method selection

Compared with pasting steel plate reinforcement, pasting carbon fiber reinforcement has more prominent advantages. The carbon fiber material is light and strong, resistant to high temperature and corrosion, and the construction is easier. For the specific situation of this project, on the one hand, there is a certain corrosive environment in thermal power plants, on the other hand, when the flue is in operation, the surface has a higher temperature, which is more suitable for the use of carbon fiber. Therefore, this project decided to use carbon fiber as a method to strengthen the main structure.

Structural reinforcement scheme

1) Classify all cracks. The crack width is not less than 0.2mm for grouting, and the crack width is less than 0.2mm for surface sealing.

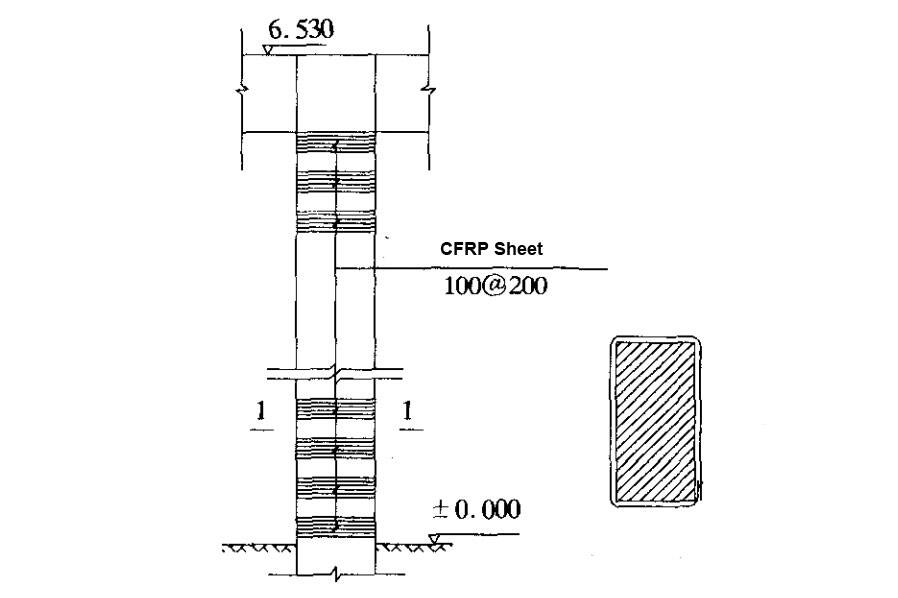

2) The main load-bearing structures such as frame columns, beams and flue bottom plates are reinforced with carbon fiber cloth. Most of the main load-bearing structures are basically intact, and the carbonization depth is less than the thickness of the protective layer of the steel bar, which will not cause damage to the steel bars in the short term. Although the actual strength of the concrete is lower than the original design strength, the gap is not too large. Since the operating load and other conditions of the structure have not changed, refer to the original design drawings of the structure and the inspection and appraisal results, and calculate in accordance with the relevant national regulations to determine the workload of pasting carbon fiber.

3) After the crack treatment and the construction of pasting carbon fiber, a comprehensive anti-corrosion treatment is carried out on the main frame and all the concrete structures of the flue body.

4Key points of structural reinforcement construction

1) The crack grouting adopts injection-type low-pressure and low-speed grouting technology, using epoxy resin glue with low viscosity, high strength, high permeability and controllable curing time. When sealing, it is necessary to first use a machine to carve a "u"-shaped groove along the crack direction, and then clean and apply glue to seal it.

2) Pasting carbon fiber has been used in China for many years, and its construction technology has been relatively mature. There are two key points that need to be emphasized in construction:

a. The quality and deployment of adhesive structural adhesives. First of all, the adhesive must be a qualified product that meets the relevant national regulations. Secondly, the construction site must be deployed and operated in strict accordance with the specified use environment and operating requirements, otherwise it will affect the strength of the colloid and even cause the colloid to fail completely in severe cases.

b. Treatment of pasting surface. The concrete adhesive surface must be polished, cleaned, leveled, repaired, and blown to ensure that the adhesive surface is flat, clean, and dry to ensure the adhesive effect, and the repair material must have a good bonding performance with the base material.

3) Anticorrosion adopts epoxy resin anticorrosive paint with certain permeability and toughness, high strength and anti-aging.

Conclusion

The flue structure has been in operation for more than 3 years since it was reinforced, and all aspects are in a safe state, indicating that the reinforcement effect is good. Carbon fiber reinforcement technology has unique advantages, it is safe and reliable, construction is quick and convenient, the effect is remarkable, and it has a wide range of popularization and application value.