Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Prestressed CFRP laminate for retrofitting bridge

In recent years, with the rapid development of the national economy, my country's transportation industry has a large-span and unconventional development in terms of construction scale and construction standards.

As a part of the traffic road, the load of the bridge presents the following characteristics:

(1) The traffic volume keeps increasing;

(2) Heavy vehicles and overloading are serious; (3) Over-limit transportation increases. Due to the limited load-bearing capacity of bridges, many bridges are overwhelmed by cracks, subsidence and other damage.

The bridge is the throat to ensure the smooth flow of the road, and the inspection and reinforcement of the old bridge is imminent.

Compared with traditional reinforcement methods, prestressed carbon fiber reinforcement technology has the following advantages:

(1) The cross-section and dead weight of the components are not increased, fatigue resistance and durability are good, and construction is convenient (without interrupting traffic).

(2) No worries about the large number of drilling holes destroying the structure, no hidden dangers of welding quality and safety, and no pollution of wet working environment.

Project Overview

The current bridge is a 12-span 20m simple-supported slab bridge, the main bridge, the total width of the bridge is 24_5m, and the deck is arranged with 50cm anti-collision guardrails + 23.5m carriageway + 50cm anti-collision guardrails. The current cross section of the bridge is divided into 3 parts, the middle part was built in 2000, and the design standard is road-class 11 load. The partially widened bridges on both sides were built in 2008, and the standard is Highway-I. When the bridge is widened, the side beam of the middle old bridge is used to move to the outside of the widened bridge

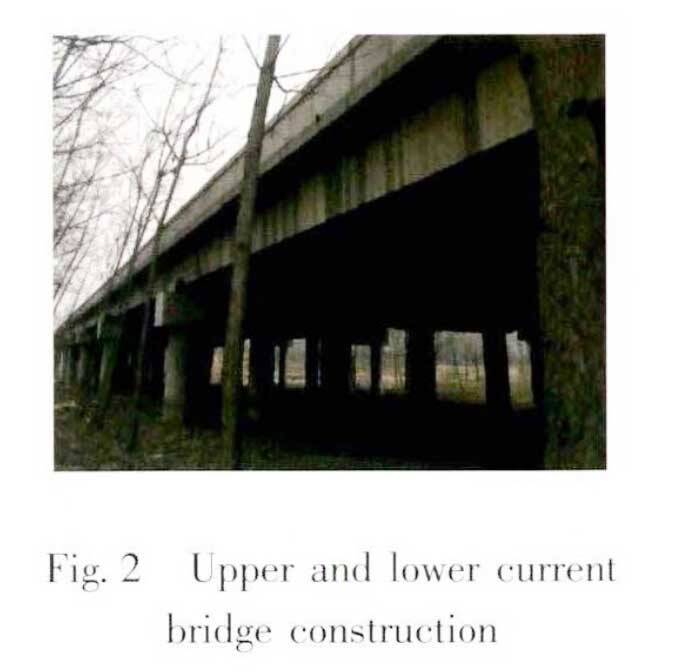

At present, the upper structure of the bridge is a reinforced concrete T-shaped main beam, and the deck is pavement made of 12cm reinforced concrete cast-in-place. Every 4 spans are 1 joint and 1 expansion joint, and each joint is set between 2 spans. The lower structure adopts makeup columns to connect the beam girder piers, embedded ribs to connect the beam girder abutments, and the makeup foundation is drilled and poured. Cone slopes are set at the abutments on the east and west sides, and the existing bridge upper and lower structures are shown in Figure 2 respectively.

Original bridge test results

(1) The current bridge is designed according to the highway-n grade, and the side beams do not meet the highway-n grade bearing capacity requirements. It is recommended to change the plate or carry the load. The middle main beam has just met the load-bearing capacity requirements, and the deflection of some beams is too large. The main beam should be strengthened to increase the structural rigidity and load-bearing capacity.

(2) The main girder of the existing bridge according to highway-I design part meets the design requirements.

(3) The horizontal connection of the main beam is weak, and the diaphragm is severely damaged; the appearance is damaged, and the ribs are exposed.

Main beam reinforcement plan

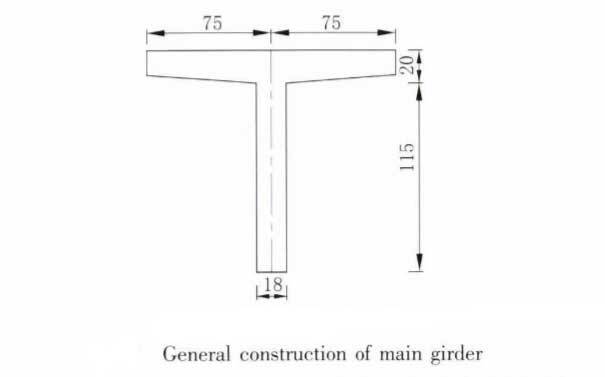

At present, the main beam is a reinforced concrete structure. The total width of the upper flange is 150cm, the height is 135cm, the width of the web is 18cm, the length of the single-span main beam is 1996cm, and the structural dimensions are shown in Figure 7.

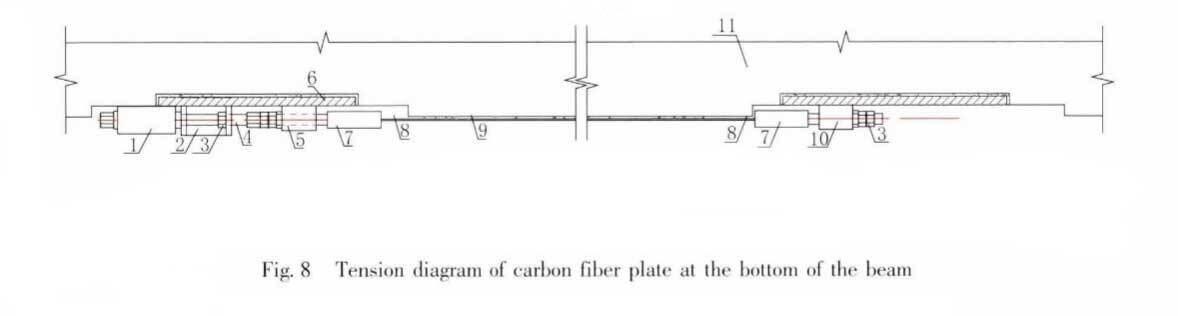

According to the test results of the original bridge, the main beam structure of the middle part of the bridge needs to be reinforced to improve the stiffness of the members and the bearing capacity of the section. Combined with previous engineering cases, consider using prestressed carbon fiber plate with more obvious reinforcement effect for reinforcement.

3.0mm prestressed CFRP plate

Sum up

The prestressed carbon fiber plate reinforcement technology can reduce the deflection of the structure, reduce the deformation of the structure, and increase the ultimate bearing capacity of the reinforced member and the bending rigidity of the structure. Compared with the traditional passive plus, it can effectively heal cracks of existing bridge structures, resist new structural cracks, and extend the service life of bridges.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.