Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

CFRP reinforcement and crack injection repair

Project Overview

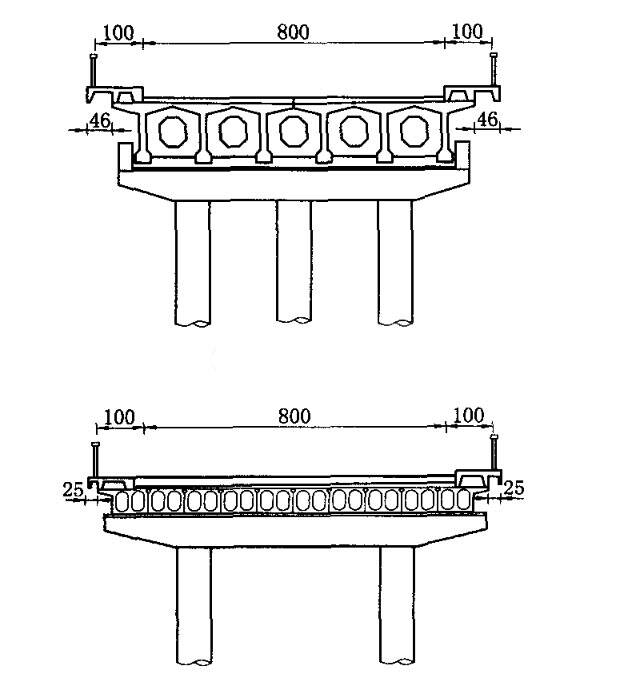

The Longgang Bridge is a concrete bridge on the third-level highway in the township. The total length of the bridge is 395 m, and the span layout: 8*13 m (large orifice plate) 10 8X*25 m (prestressed T beam) 10 8*13 m (large orifice plate). The section of Longgang Bridge is shown in the figure. The total width of the bridge deck is 10 m, and its layout: 1 m (sidewalk) + s m (motor vehicle lane) + 1 m (sidewalk). All piers of the bridge adopt a reinforced concrete double-column structure with capped beams; the bridge foundation adopts m bored piles except for the 7 water piers of the main span, which adopt 10 50 cm×50 cm prestressed reinforced concrete square piles. The bridge was built in 1988.

In September 1998, rush repairs were carried out due to a major accident in which the piers of the bridge were destroyed by a ship collision. The main girder, span, load rating and navigation standards of the repaired part were the same as the original bridge.

Bridge disease status

(1) The maximum width of the joint is 0.21 mm, and the length is different. Some of the transverse cracks near the mid-span position are long and extend to the web.

(2) There are longitudinal cracks in part of the large-hole slab bridge span. The maximum crack width is 0.33 mm, and the longest is close to 1/2 of the slab length. The beam bottom plate is in a cracking state.

(3) There are obvious transverse cracks near the bottom of the downstream pier of Pier 3, with a width of 0.21 mm, a depth of 7.2 cm, and a length of 2.5 m.

(4) A large transverse penetration crack appeared in the middle of the lower beam of Pier 14 and the crack extended to the bottom of the beam with a width of 2.53mm.

5) There is a hollow area of 30 cmXZO cm at 1.4 m of the lower beam of the No. 14 pier, and there are 6 longitudinal cracks on the outer surface with a maximum width of 0.31 mm.

(6) The outer surface of the bottom of piers 17-19 is severely eroded, the coarse aggregate is broken, and there are vertical cracks.

(7) The pavement of the entire bridge deck was severely damaged, and many steel meshes were exposed. Part of the sidewalk has collapsed due to uranium solidification problems, the expansion joints of the entire bridge are damaged to varying degrees, and the connection between the expansion joints and the pavement concrete of the bridge is not smooth.

The expansion joints and railings of the bridge deck are seriously damaged, the drainage system is not smooth, there are serious water seepages in many places, and the bridge deck is seriously damaged. The crack width of the main beam part of the superstructure has exceeded the requirement for crack width, which is detrimental to the durability of the structure. The substructure is mainly cracks at the bottom of the piers and exposed coarse aggregates. According to the results, the technical condition of Longgang Bridge is classified into four types of bridges based on the worst defect condition of important components.

Bridge reinforcement scheme design

Repair structural defects and restore its integrity

(1) Treat the transverse cracks in each large-hole slab girder, some longitudinal cracks in the large-hole slab girder, the cracks in the pier column and the cracks in the crossbeam of No. 14 pier, according to the crack width to restore the durability of the structure.

Principle of crack treatment: According to the width of the crack, it is treated according to the width. When the crack width is 8 Yan 0.20 mm, epoxy mortar is poured into it; when the crack width o<O.20 mm, epoxy mortar is used for sealing treatment.

(2) Fill the cavities of the beam with epoxy mortar.

Beam reinforcement

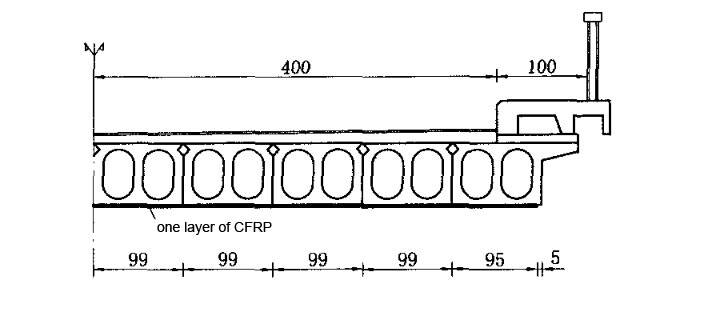

The carbon fiber cloth is pasted to the bottom plate of the large-hole slab beam of the full bridge to limit the cracks of the beam bottom plate from cracking under the vehicle load, thereby enhancing the bending rigidity of the beam body.

Repair and reinforcement of diseased bridge piers

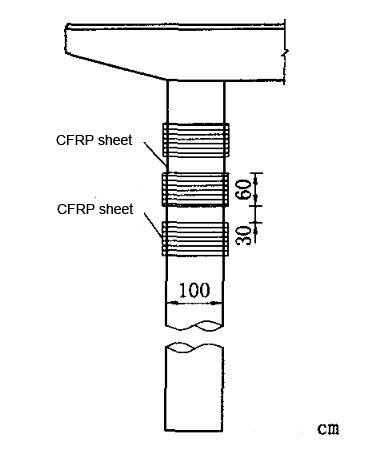

In view of the obvious lateral crack disease near the bottom of Pier 3, the outer surface of the pier bottom of Pier 17-19 is severely corroded, the coarse aggregate is exposed, and the vertical crack is damaged, the cracks should be treated first. Then paste the circular carbon fiber cloth and vertical carbon fiber cloth on the diseased part of the bridge pier to limit the continuous expansion of the cracks of the bridge pier, as shown in the figure

Aiming at the 30cm X 20 cm hollow area and longitudinal cracks at 1.4 m of the lower beam of the No. 14 pier, the hollow area concrete was broken up first, and then the hollow area was filled with epoxy resin cement. Finally, paste the horizontal carbon fiber cloth and the longitudinal carbon fiber cloth in the repaired area and the area with longitudinal cracks to limit the continuous expansion of the cracks of the bridge pier.

Features of the CFRP reinforcement and crack injection scheme

This design scheme is designed on the basis of detailed inspection and static and dynamic load tests of the bridge. The design scheme has the characteristics of clear stress, simple construction technology and low investment cost.

Conclusion

(1) Adhesive reinforcement is adopted in the reinforcement design for slab girder and bridge piers. The plan is safe, reliable, and economical.

(2) After structural repairs are not foolproof, stricter maintenance and management should be carried out. Anti-collision facilities and more eye-catching anti-collision warning signs should be installed on the main channel piers, and overweight vehicles should be controlled to ensure structural safety.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength crack sealing repairing adhesive for the fracture surface of concrete crack

Very strong penetration and low viscosity epoxy crack injection adhesive for repairing concrete crack

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.