Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

prestressed carbon fiber plate on the bridge

Project Overview

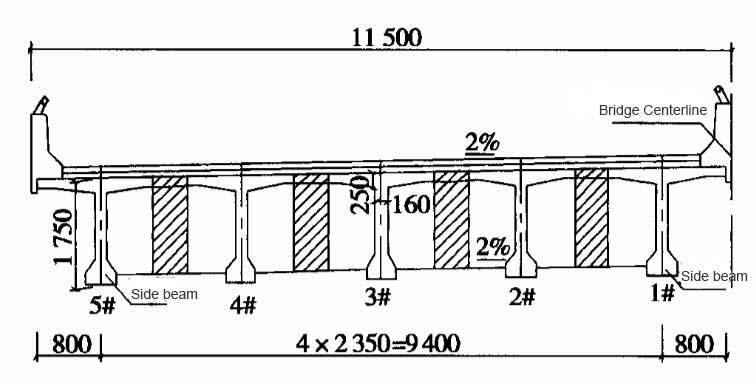

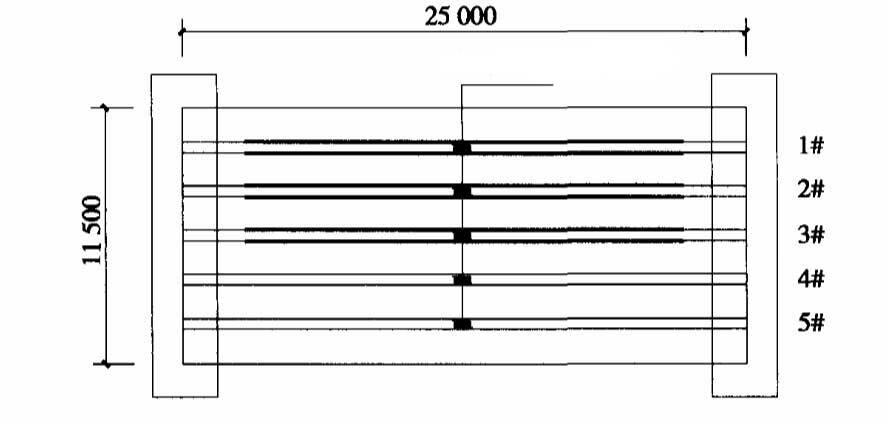

A bridge has a total length of 456.91 m, a bridge deck width of 23 m, a highway grade of two-way 4-lane highway, and a load grade of highway I. The upper part of the bridge girder is a 25 m span prestressed concrete simply supported T-beam, asphalt concrete bridge deck pavement, the road surface is sloped from the middle ridgeline to 2% on both sides, Mauler expansion joint, and plate rubber bearing. The lower part is a double-column bridge pier and light bridge abutment. After 16 years of operation, the bridge has suffered varying degrees of damage. During regular inspections in September 2011, it was found that some of the T-beams have suffered from horseshoe edge cracking, deflection deformation, diaphragm concrete damage, local steel bar rust expansion, pavement cracking and rutting. The monitoring data shows that the most damaged is the 1# beam. Tensile stress appears from the position of 1/3 of the span of the support to the lower edge of the mid-span area, which does not meet the crack resistance requirements, and some diseases have developed rapidly. The trend is that the reinforcement of bridges cannot be delayed. See Figure 1 for the bridge 1/2 cross section.

Prestressed carbon fiber plate reinforcement plan

The 1# beam, 2# beam and 3# beam belong to the general disease category 3 T beam. After comparing various schemes, it was decided to use prestressed carbon fiber plate for reinforcement.

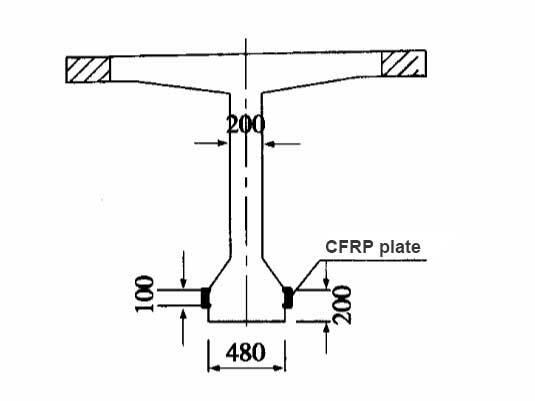

First, repair the cracks and local damages with acrylic milk mortar or acrylic stone concrete. Then, the 1# beams, 2# beams and 3# beams with severe damage were externally reinforced with prestressed carbon fiber plates. The tensile control stress of the prestressed carbon fiber plate is 960 MPa, the tensile control force is (0.4 X 2 400×200) N=192 kN, the carbon fiber plate specification (width×thickness) is 100 mm×2 mm, and the length is 21 m, arranged on both sides of the beam at a distance of 100 mm from the bottom of the beam, using one end to be tensioned at the same time, the prestress loss is 10% to 15% of the tension control stress.

In conclusion

(1) The prestressed carbon fiber plate reinforces the existing bridge structure with certain damage and disease, which can significantly reduce the tensile stress at the bottom of the reinforced beam, and the reinforcement effect is obvious. In addition, the transverse connection of the entire bridge can increase the bearing capacity of the unreinforced part of the beam to a certain extent, resulting in a good overall effect.

(2) Reinforced concrete bridges with prestressed carbon fiber plate, there are different levels of tensile stress along the longitudinal, horizontal and vertical parts of the contact portion of the carbon fiber plate and the concrete member, which tends to cause the carbon fiber plate to peel off from the concrete surface. Improper handling will cause secondary damage to the structure, so measures should be taken to prevent it.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.