Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Comparison of bonded steel plate and bonding carbon fiber for beam strengthening

Project Overview

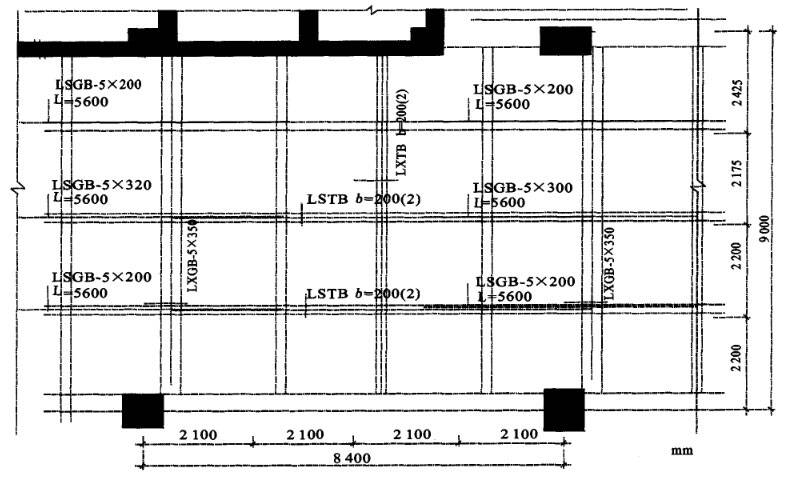

CCCC Yihang Building is located in the shipping service area of Tianjin Free Trade Zone, with a construction area of 35 216 m2, 1 underground floor, 23 floors above ground, and 1-3 floors are podiums. The structure is a frame-shear wall structure with east-west axis. The span is 8,400mm, the north-south axis span is 9 000mm, the frame beam section size is 400mm×650mm, and the secondary beam size is 200mm×500mm.

Due to the functional changes of the 4-story house, the 3-story top beam will be reinforced by sticking steel plates on the lower part of the frame beam and at the negative moment of the support, and bonding carbon fiber on the upper part of the secondary beam. For the beam with steel plate glued on the lower part, stick two steel plates on each end of the beam with a 3×100 U-shaped hoop. A beam with carbon fiber cloth glued to the lower part of the beam, two carbon cloth u-shaped hoops b=100mm on each end of the beam, and a longitudinal waist steel bead on each side of the waist of the frame beam.

Comparison of bonded steel plate and bonding carbon fiber for strengthening

Nowadays, the bonding steel strengthening and the bonding carbon fiber strengthening in the concrete are often used in the reconstruction and strengthening projects of the building structure, and the positions of the bonding strengthening are also roughly the same. Based on the construction experience, the steel plate and carbon fiber cloth used in this project are now compared in terms of physical properties, construction technology, improving component bearing capacity, cost, and market analysis.

1) Physical properties of steel plate and carbon fiber materials

Both steel and carbon cloth are materials with high tensile strength, especially the tensile strength of carbon fiber cloth is more than 10 times that of ordinary steel. The physical properties of steel and carbon fiber cloth materials are very different, which is also a key consideration when designing strengthening schemes. The commonly used steel Q235 is well known in the construction industry and its quality is relatively stable. The newer carbon fiber cloth has a special transformation. The currently used carbon cloth has a mass of 200-600 g/m2 and a thickness of only 0.111-0.333 mm. The total thickness of the pasted construction is not more than 3 mm, and compared to the reinforced concrete component, there is basically no increase in weight. This is a major advantage of pasting carbon fiber cloth, and it will not affect the surface layer of the component after construction. To ensure the quality of the reinforced concrete structure, the carbon fiber cloth used by our company is a product of Horse Construction with excellent performance and quality.

2) The binder used.

The main materials of the binder are very similar. For example, companies that produce adhesives for steel structure have also begun to produce adhesives for carbon cloth. The main component is epoxy resin, which is generally divided into two components: main agent and curing agent. It is even in a certain proportion, has good workability within a period of time, is convenient for construction, and starts to solidify after a period of time. The two construction methods are also similar in terms of acceptance criteria. In addition to the appearance inspection, the quality of the adhesive is an important part and can be tested by experiments. Another important acceptance is that the hollow rate limits are different, but the detection methods are the same. For carbon cloth pasting construction inspection, if the bonding area is less than 95%, it is judged that the bonding is invalid and needs to be re-construction. For steel plate pasting construction inspection, if the effective bonding area of the anchoring area is less than 90%, and the effective bonding area of the non-anchoring area is less than 70%, the steel plate should be peeled off and pasted again.

3) Construction timeliness and space.

When sticking carbon cloth, there is no need to set up a pressure system. Compared with sticking steel, the construction process is simple, the construction speed is fast, and the construction space is small. Only 1 to 2 people are required to operate a working surface. Each skilled worker can complete nearly about 200 m2. For the same amount of work, the construction period of sticky carbon cloth is about 40% of sticky steel

(4) Base surface treatment.

Both the sticky steel and sticky carbon cloth require a solid surface of the concrete component, remove the carbonized layer, and be smooth and clean when the base surface is treated. However, the surface treatment of steel is more complicated than that of carbon cloth. It needs to be polished to give a metallic luster, and the grinding pattern is perpendicular to the force direction. Carbon cloth only needs to wipe the adhesive surface clean and keep it dry.

(5) Comparison of carbon fiber strengthening and bonded steel strengthening in improving the bearing capacity of components.

The steel plate and carbon cloth are pasted on the beam and the bottom of the plate to enhance the bending resistance of the component, and pasted on the side near the beam support to improve the shear resistance of the component. However, the shear strength of carbon cloth is much lower than that of steel. Now the design of pasting carbon cloth does not consider its shear resistance, so some designs still prefer to stick steel to strengthen. Especially in the demolition and strengthening of damaged components in structural transformation with more complex forces, the strengthening method of the beam side and the negative moment of the support in this project is to stick steel plates, which is also considered.

Carbon fiber strengthening and bonded steel strengthening can improve the bearing capacity of components to a certain extent, but neither strengthening method is omnipotent. Because carbon fiber strengthening and bonded steel strengthening are carried out on the basis of the original components, the cross-sectional size, strengthening, and concrete strength grade of the original structure limit the extent to which they can play a role.

6) In terms of cost.

The Q 235 b steel plate with a section of 5 mm X 100 mm can provide a design strength of about 5 X 100 X 215 =107 (kN). If it is changed to a carbon fiber cloth with a width of 100 mm and a thickness of 0.167 mm, the design strength of the carbon cloth is assumed to be 3 500 MPa. Then the design strength provided by the carbon cloth is 0.167 X 100 X 3 500=58 (kN). Roughly speaking, the strength of a layer of 5mm thick steel plate is equivalent to that of two layers of carbon cloth. But sticking a 5 mm thick steel plate is more expensive than sticking a double-layer carbon cloth.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Two-component epoxy modified epoxy structural strengthening adhesive for bonded steel plate to concrete

Modified epoxy resin structural perfusion adhesive, specifically for supporting adhesive bonded steel reinforcement

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.