Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

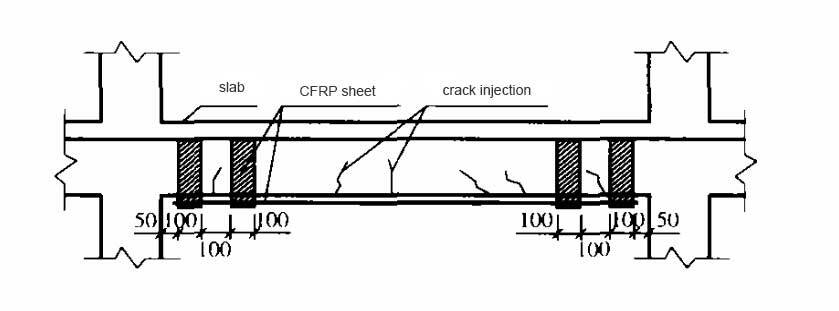

Carbon fiber fabric reinforced concrete crack beam

Overview

An 8-story building in a factory in Xiangfan City, with frame structure and pile foundation. Due to the uneven settlement (up to 12 cm), most of the beams on the 1st to 6th floors of the plant have many cracks with a width of 0.2-4.5 mm, and some of the beams penetrate the full height of the beam. After appraisal, the reliability of the member is C grade, and the beam should be reinforced immediately. Taking into account the complex construction conditions on site, the large amount of works, and the tight construction period, after comparing multiple options, it was decided to use carbon fiber fabric reinforcement technology for reinforcement treatment.

Carbon fiber for beam reinforcement construction scheme

The beam of the plant is tested according to the requirements of the design unit, and its reliability is rated as Class C. The beam needs to be strengthened in terms of safety, applicability, and durability. Based on empirical calculations, it was decided to use the "u" shaped fabric anchor to reinforce the two-layer carbon fiber cloth.

Step 1: Unload the floor. Move all the facilities in the second to seventh floors of the factory that need to be reinforced. After the reinforcement is successful, move it back to the original place to reduce the stress lag of the reinforced carbon fiber cloth and ensure that the carbon fiber cloth and the concrete beam work together.

Step 2: Reinforce cracks with glue. All cracks are sealed with sealant first, and then the compressor is injected with glue to seal the cracks to achieve the effect of reinforcing the concrete.

Step 3: Paste reinforced with carbon fiber cloth. Attach two layers of 10 em wide carbon fiber cloth to the bottom of the beam, and anchor the bottom carbon fiber cloth with "u" carbon fiber cloth at both ends of the beam.

Conclusion

After about one year of use, the plant has been strengthened and no cracks have occurred. The original beam with large deflection also showed no obvious deformation, indicating that the carbon fiber cloth strengthened the beam successfully. At the same time, it also reflects the advantages of carbon fiber cloth reinforced components:

(1) Wide range of application occasions, especially where the construction space is narrow;

(2) The construction is convenient and the work efficiency is high. The construction does not require large machinery and tools, only simple tools such as hand-held grinding wheel polishers, brushes, etc. The finished carbon fiber cloth is a coiled fabric, which can be arbitrarily cut like a cloth and easy to operate. The plant beam is strengthened by approximately 100 m and completed in 10 days;

(3) The construction is simple, the operation on the back is also easy, the success rate is basically 100%, and it is easy to ensure the quality.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

Good impregnation carbon fiber adhesive for applying carbon fiber reinforced polymer(CFRP) wrap for structural strengthening

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.