Reinforcement of compression steel tube

Carbon fiber reinforcement

Carbon fiber wrap reinforcement is a new technology developed in the past ten years. This method has simple construction and operation, and the required construction period is short, which affects the short operation time of the unit. Compared with traditional methods, it has obvious advantages.

Introduction

The traditional methods of reinforcement and reinforcement of pressure steel pipes generally include three types of local pipe replacement (tile reinforcement), casing reinforcement and outsourcing reinforced concrete reinforcement. However, these traditional reinforcement methods require the unit to shut down water and power, and the reinforcement period is longer, which has a greater impact on production. Carbon fiber wrap reinforcementis a new technology developed in the past ten years. This method has simple construction and operation, and the required construction period is short, which affects the short operation time of the unit. Compared with traditional methods, it has obvious advantages.

Introduction of the project

The project is located about 1km upstream of Longting Waterfall in Gutian County, Fujian Province. The water conservancy hub is composed of barrage dams, bank-like water inlets, diversion tunnels, surge wells, high-pressure pipelines, ground plants and switch stations. The total installed capacity of the power station is 2x65MW, and the first unit was put into operation on March 30, 1969. The second unit generated electricity on August 28, 1973, and the project was basically completed by the end of the same year. The power station is mainly responsible for frequency modulation, peak shaving, phase modulation and grid backup tasks. The high-pressure pipeline of the power station is about 274m long, the slope is 1: 1.7, the inner diameter of the steel liner is 6.4m, the thickness of the concrete is 60cm, and the local pipe is supplemented with steel plate concrete, and the inner diameter gradually decreases to 5.0m. The branch pipe 1 and the branch pipe of the machine are 33.6m long, the inner diameter is 4.0m, the open pipe section of the pressure steel pipe, the maximum head is 125.0m, the minimum head is 105.0m, the design head is 108.0m, and the rate of increase of the water pressure during load rejection is 56.54 %.

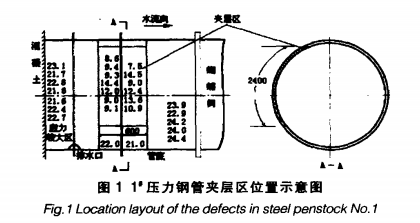

Pressure steel tube status

In view of the fact that the pressure steel pipe has been used for more than 30 years, the material has a certain degree of aging, the steel pipe is seriously corroded, and there are obvious interlayers. Its stress exceeds the design specification, and it can no longer meet the requirements of the current specification. Therefore, in order to ensure the safe operation of the pressure steel pipe, it is recommended to reinforce the pressure steel pipe.

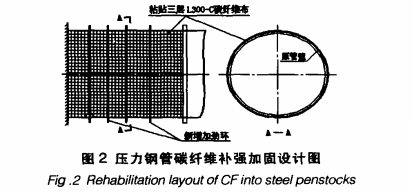

Reinforcement of steel pipes with carbon fiber wrap

The high tensile strength of the composite composed of carbon fiber cloth and steel plate is used to increase the tensile strength of the pressure steel pipe. The specific method is: clean and clean the surface of the steel pipe, level and roughen the part to be pasted, apply and paste the carbon fiber type structural adhesive. Then paste a layer of carbon fiber cloth with a thickness of 0.167 mm on it, and so on, and paste a total of 3 layers of carbon fiber, and finally apply impregnating resin on the surface of the third layer of carbon fiber (see Figure 2).

300g carbon fiber wrap

Conclusion

Carbon fiber materials have superior mechanical properties and good anti-corrosion effects. The use of carbon fiber reinforcement can greatly increase the load-bearing capacity of pressure steel pipes. It also has the advantages of short construction period, easy construction, and easy quality assurance. At present, the application of carbon fiber materials in engineering is becoming more and more widespread, and it has a very good development prospect.

By Liu Lihua