A hotel retrofit

Carbon fiber reinforced hotel

After comprehensive consideration, it was decided to use carbon fiber reinforced polymer(CFRP) for the reinforcement of beams and slabs.

Project Overview

A large wine shop in Hefei is located in the Longgang Economic Development Zone in Hefei. It was originally designed as a 7-layer steel-reinforced concrete frame structure. The column spacing is 5.4m and 6.6m in the horizontal direction, and 7.8m in the vertical direction. The total construction area is 13,000 square meters, and the foundation is an independent column foundation. In May 2004, the proprietor proposed to increase the function of the restaurant, and proposed to use part of the function to change the building, and changed the dining halls on the second and third floors into bathrooms. In order to meet the requirements of the use of the restaurant, the original structure must be strengthened and transformed. The project was completed in October 2004 and was rebuilt and put into use, achieving good economic results.

Major issues in rehabilitation

(1) The floor load increased significantly. The original design has a constant load of 5kN / m, which is increased to 15kN / m after modification, and the live load does not change. At this time, the main body of the building has been completed, and it is not possible to increase the structural load-bearing capacity by changing the reinforcement or increasing the dimensions.

(2) Owners are not allowed to reduce the clear floor height, and they are required to reduce the damage to the original structure as much as possible, and the reliability of the reinforcement method is good.

(3) The scope of reconstruction is wide, the area is large, and the construction period is short.

Confirmation of the reinforcement plan

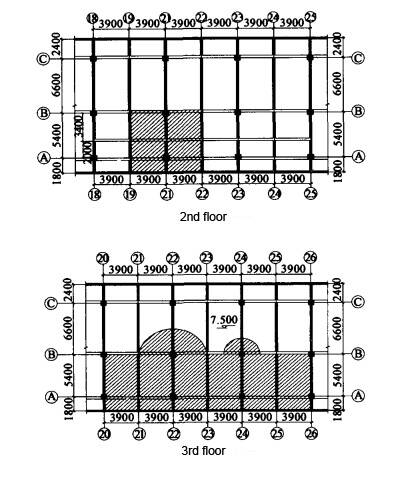

First of all, according to the requirements of the owner, determine the height and layout of the bath room. The layout of the 2-layer bath room is shown in Figure 1, and the layout of the 3-layer bath room is shown in Figure 2.

Carbon fiber is a high-strength new material with high strength, light weight, thin thickness, good durability, etc., and does not increase the structural weight after reinforcement, does not occupy the original building space, does not damage the original force components, and the construction is convenient and reliable , Widely used in reinforcement and transformation projects. After the carbon fiber cloth is attached to the concrete structure, a composite structure is formed, and the deformation of the concrete structure and the carbon fiber cloth are coordinated to work together to achieve the purpose of strengthening and strengthening and improving the structural performance. After comprehensive consideration, it was decided to use carbon fiber cloth for the reinforcement of beams and slabs.

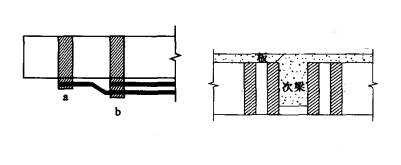

In this project, carbon fiber fabric with a width of 300 mm and a thickness of 0.167 mm is used to reinforce the beam and slab. Among them, the bending moment at the bottom of the beam: KL23, LL16 paste 2 layers, KL26 paste 3 layers, KL27 paste 4 layers. Negative bending moment area at the top of the frame frame beam: two layers of 300mm wide carbon fiber cloth are stuck on each side of the frame frame column, and the length is taken as 1/4 of the beam span. Negative bending moment area of the secondary beam top: two layers of 300mm wide carbon fiber cloth are pasted, and the length is 1/4 of the beam span. Board B05: A layer of carbon fiber cloth with a width of 300mm and a spacing of 300mm is adhered to the bottom bending area of the bottom of the board. Two layers of carbon fiber cloth with a width of 300mm and a spacing of 300mm are pasted on the negative bending moment area of the top of the board.

In conclusion

For structures designed according to the principle of strong columns and weak beams, the bearing capacity of columns and foundations can generally meet the requirements.

In the process of reinforcement and reconstruction, beams and slabs are weak components, and their load-bearing capacity generally cannot meet the requirements, and reinforcement is required.

When the bottom of the beam is pasted with multiple layers of carbon fiber, it should be cut off in layers as much as possible, and the inner and outer lengths should be adopted.

When the bottom of the beam is reinforced, U-shaped hoops should be installed at both ends and the middle of the carbon fiber cloth as an additional anchoring measure to prevent the carbon fiber cloth from peeling and breaking.