Building floor reinforcement

reinforcement with high strength carbon fiber

This project adopts the method of pasting high strength carbon fiber to strengthen the situation where the negative reinforcement of the floor is trampled. It has been completed for two years. After regular inspection and observation, no structural abnormalities were found.

Project Overview

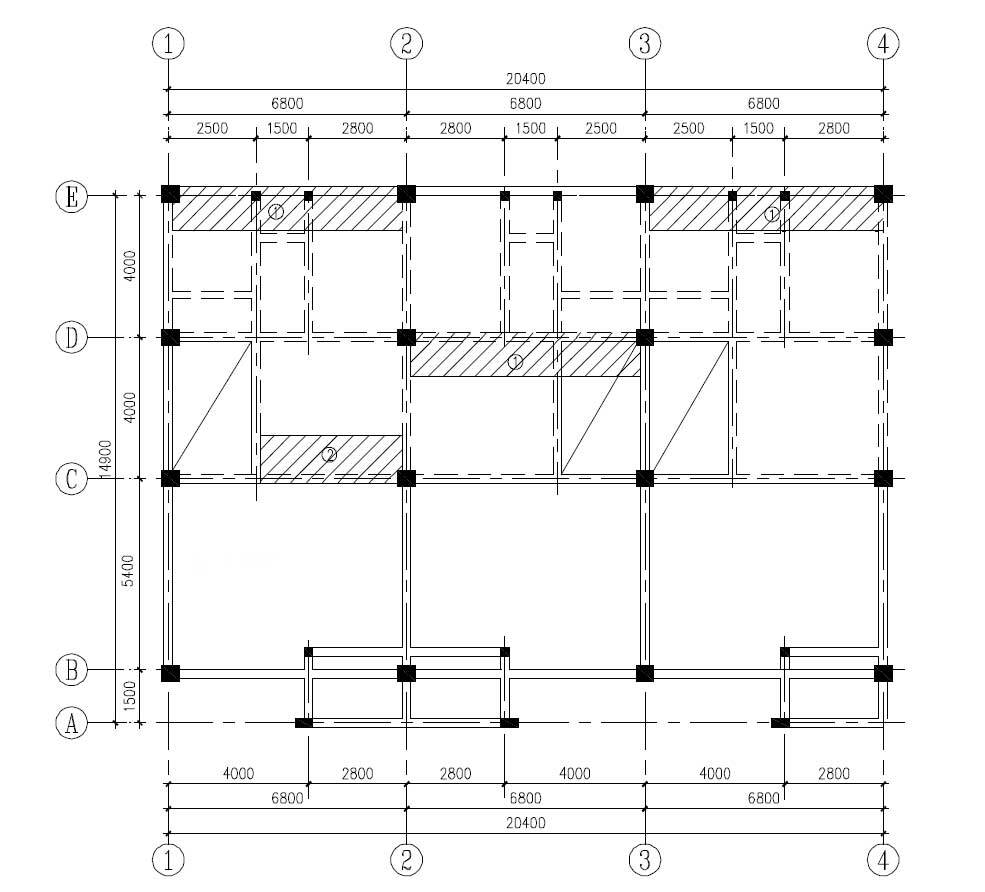

A certain building in Kunshan found that the thickness of the protective layer of the negative steel bar in an area floor slab (the thickness of the floor slab is 120mm) is too close to about 80mm-90mm. After analysis, it may be that during the construction process, the construction personnel did not pay attention to trample the negative reinforcement on the floor surface. Therefore, the thickness of the negative reinforcement protective layer of the floor slab in this area does not meet the requirements during the completion acceptance, and the floor slab needs to be strengthened so that the bearing capacity of the floor slab can meet the design requirements. Reinforcement design is carried out according to the reinforcement diagram of the first floor of the original structure (the project has a basement). The area to be slab-reinforced is shown in Figure 1. The shaded area is the area to be slab-reinforced (negative rebar stepped area). This article focuses on the floor reinforcement design and construction plan.

Comparison and selection of reinforcement schemes

The thickness of the first floor is 120mm, and the thickness of the floor is 160mm. In the first figure, the shaded area ① the negative reinforcement of the plate is 8@200, and the shaded area ② the negative reinforcement of the plate is 10@200. Because the thickness of the negative reinforcement protection layer in the shadow area is too thick, the negative reinforcement on the plate surface cannot meet the load-bearing requirements of the original design and must be reinforced. At present, the common methods of strengthening such floor slabs generally include schemes such as sticking steel strips to the floor and sticking carbon fiber cloth. Each scheme has its advantages and disadvantages and different scope of application. The two schemes for floor slab reinforcement in this project are compared and selected below.

The reinforcement principle of the steel plate paste reinforcement scheme and the carbon fiber cloth reinforcement scheme is basically similar, that is, the negative steel reinforcement of the original floor slab is replaced by the steel plate or the carbon fiber cloth to replace the negative steel bar bearing capacity of the original floor slab. We mainly consider the following points when choosing a reinforcement plan.

1. Construction process and duration

Adhere to carbon fiber reinforcement, the construction process is simple, and the construction period is short (because carbon fiber cloth does not require anti-corrosion treatment like the steel plate itself, and the carbon fiber cloth is easier to bend than the steel plate when pasted at the corner);

2. Reinforcement cost

The use of bonded carbon fiber cloth reinforcement saves about 25% of the reinforcement cost compared with the use of bonded steel plate reinforcement. The reinforced value of the floor slab where the negative reinforcement of the floor slab support of this project is stepped on is not large. If the steel plate method is used for reinforcement, although the theoretical calculation of the reinforcement steel plate area is less than that of carbon fiber cloth, the actual structural construction measures need to be met. Therefore, the area of the pasted steel plate used is not less than the area of the carbon fiber cloth, and the unit cost of the bonded steel plate is 25% higher than the unit cost of the bonded carbon fiber;

3. Strengthening effect

Both reinforcement schemes can ideally meet the original structural design requirements. Although the stiffness of the floor slab has also been improved by the bonded steel strip reinforcement scheme, the floor slab rigidity of this project has met the design requirements, so the reinforcement effect is basically the same.

After comprehensive consideration and comparison by the owner, the carbon fiber reinforced polymer reinforcement scheme was finally selected.

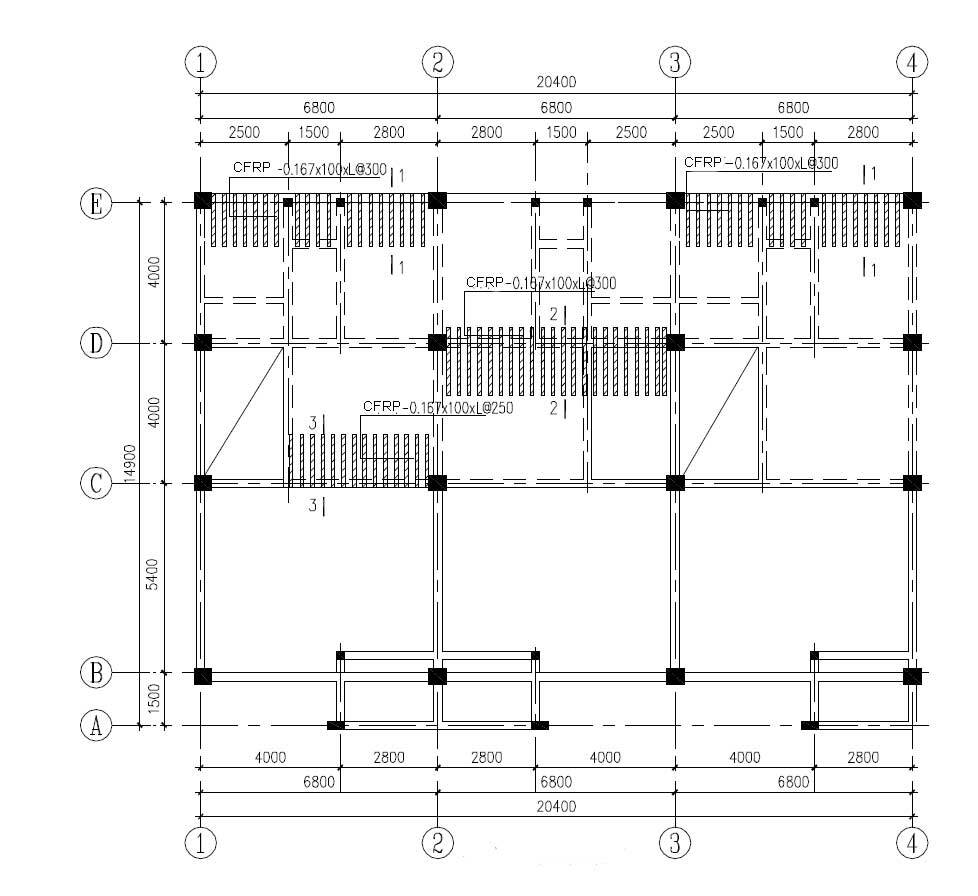

The floor plan for floor reinforcement of this project is detailed in the attached drawings

Slab strengthening materials

HM-30 unidirectional carbon fiber fabric

Conclusion

This project adopts the method of pasting carbon fiber to strengthen the situation where the negative reinforcement of the floor is trampled. It has been completed for two years. After regular inspection and observation, no structural abnormalities were found. Carbon fiber cloth has high strength, light weight, corrosion resistance and durability, simple construction, short working hours, flexibility, can wrap complex shape members, and is easy to cut. It is suitable for reinforced concrete bending, axial compression, large eccentric compression and tensile member reinforcement. After reinforcement, it can greatly improve the structural strength and safety factor, and is one of the ideal reinforcement materials.