Bridge strengthening

Bridge strengthening after flood

Bridge strengthening after flood

The article "Franklin Co. Commissioners learn bridges need at least $3M in repairs", a bridge inspector traveled Tuesday in Franklin County, Pennsylvania, looking for any damage caused by the recent floods. Even before rain, the bridge owned by the county government costs about $3 million in maintenance.

Therefore, bridge strengthening after flood is very important.

Project

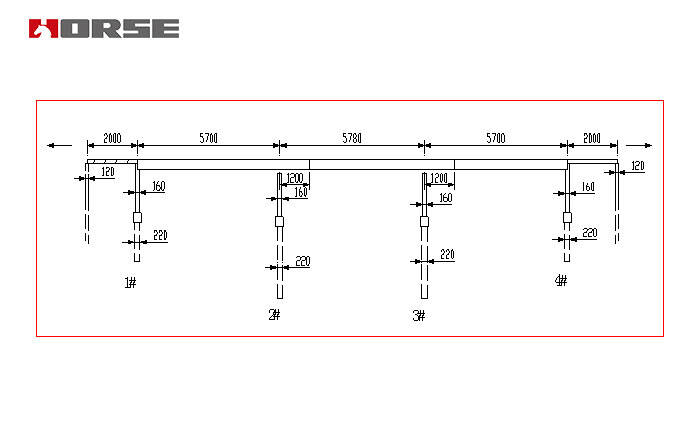

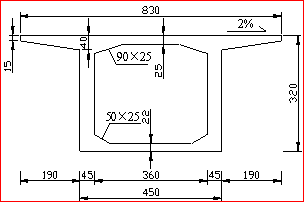

A continuous girder bridge, the overall layout is 1 *20m + (57 + 57.8 + 57) m + 1 *20m, the main girder section is a single box single-chamber box section, beam height 3.2m, box girder roof width 8.3m, thickness 25cm. The width of the floor is 4.5m, the thickness is 50-22 cm, the thickness of the web is 75-45 cm, the main beam is made of C50 concrete, and the design load is grade II of the highway.

Before April 11, 2010, the first section was poured and the second section was stretched, and the prestressed reinforcement of the second span box girder was planned to be stretched on May 6, 2010.

In the early morning of May 6, 2010, the second span of the box girder was completely destroyed by the flood. At this time, the prestressed concrete of the second section of the box girder has not yet been stretched.

Second prestressed tensioning operations were carried out in May 7, 2010.

In May 2010, the 15~30 day inspection company carried out on-site inspection and assessment of the state of the bridge after flood.

In June 2010, the third section of concrete was poured and stretched.

Main conclusions of bridge detection

The mechanical properties of the main materials such as concrete, ordinary steel bar and stranded wire meet the specifications.

After tensioning the second span, cracks are mainly distributed in the middle of the second span between L/3 and L4/5 in the range of about 24 M. The crack width is mostly between 0.01 mm and 0.08 mm. The maximum crack width is 0.11 mm and the maximum crack height is 257 mm.

Main conclusions of analysis and assessment

(1) with the measured deflection value as the criterion, the stiffness of cracked beams in different construction stages is identified.

1) The average stiffness of cracked beams after collapse and tensioned second span prestressing is 40% of initial stiffness.

2) The stiffness of the beam section after stretching second span prestressed tendons is 85% of the initial stiffness.

2) Considering the reduction of stiffness, the Yangjiang Bridge is analyzed and evaluated by the plane bar system finite element method, and the evaluation results show that the method is effective. The bending capacity of normal section, shear capacity of inclined section, principal compressive stress and deflection of the bridge can meet the requirements of the code, but the normal compressive stress can not meet the requirements of the code. The results of three-dimensional finite element analysis show that the reinforcement fails to yield after the support is broken.

Bridge strengthening and maintenance plan

1) The thickness of cast-in-situ layer of 3-span continuous box girder main bridge deck is increased from 10 cm to 12 cm, and it is used as load-bearing structural layer to participate in the structural action. In order to ensure the reliable connection between the cast-in-place concrete layer and the box girder, the vertical bonding bars must be arranged between the box girder and the cast-in-place concrete layer.

2) The modified asphalt waterproof layer is laid on the reinforcement layer, and then the 5 cm asphalt concrete is laid as the bridge deck pavement. The deck pavement from bottom to top is as follows:

12cm concrete reinforcement layer + waterproof layer +5cm asphalt concrete

The elevation of the route should be adjusted appropriately to make the elevation smooth transition.

3) For existing cracks, the actual situation of cracks after deck pavement is completed is treated separately. For cracks with width greater than 0.1 mm, the "wall method" is adopted. For the cracks with width less than 0.1mm, the inner and outer surfaces of box girders are treated by surface sealing.

4) after the cracks are treated, the inner and outer surfaces of the bridge are treated with coating to ensure the durability of the bridge.