Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Flexural Strength of CFRP Composites Strengthening System According to ASTM D7264

Introduction

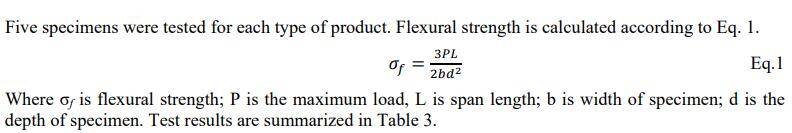

This report provides a summary of the results of test performed as outlined within this document. Flexural test was conducted following ASTM D7264/D7264M – 15. Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials. The coupon configuration was standard according to the standard specified.

Test Date and Location

The test was conducted on December 28, 2018 in material laboratory of Shanghai Zhengniu New Material Tech., Ltd., China.

Test Operator

Cheng Tan

Description of Specimens

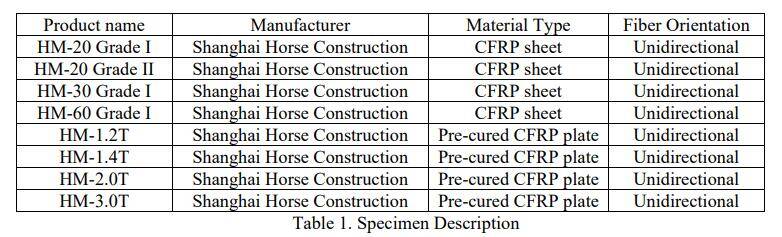

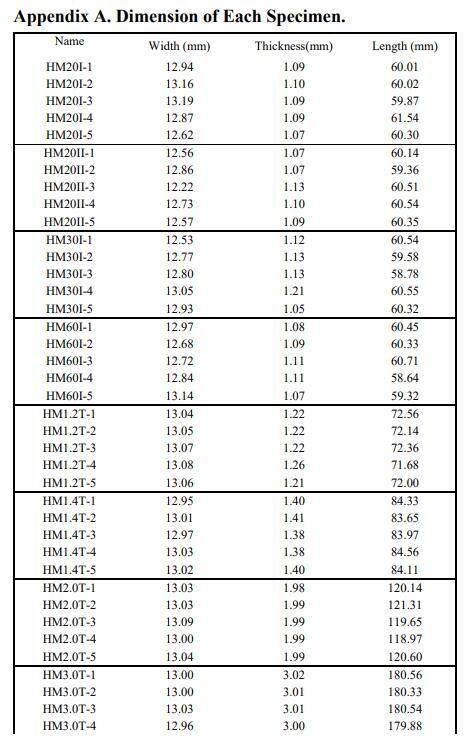

Specimens in this test were manufactured by Shanghai Horse Construction. Table 1. shows information of the tested specimens.

Specimens were labeled as HM20I-# for HM-20 Grade I, HM20II-# for HM-20 Grade II, HM30I-# for HM-30 Grade I, HM60I-# for HM-60 Grade I, HM1.2T-# for HM-1.2T, HM1.4T-# for HM-1.4T, HM2.0T-# for HM-2.0T and HM3.0T-# for HM-3.0T.

For HM-20 Grade I and HM-20 Grade II sheet specimens, each specimen was made of three layers of dry fiber with HM180C3P impregnated adhesive. For HM-30 Grade I sheet specimens, each specimen was made of two layers of dry fiber with HM180C3P impregnated adhesive. For HM-60 Grade I sheet specimens, each specimen was made of one layer of dry fiber with HM180C3P impregnated adhesive.

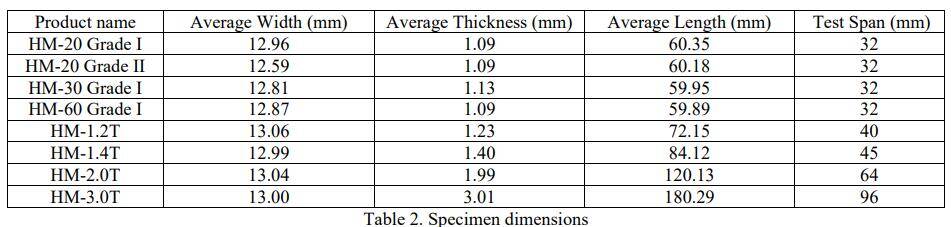

Typical flat specimen are used in this test. All CFRP sheet specimens were manufactured with three layers of dry fiber sheets, geometry of tested specimens are summarized in Table 2. Dimension for each specimen is summarized in Appendix A.

Apparatus

A 30 kN MTS testing machine (Model: E45) was used to conduct this test.

5.0 mm diameter loading nose and supports was used in this test.

Test Procedure

Tests were conducted under a temperature of 23°±3°C.

The span length was adjusted with a span to depth ratio 32:1 for all specimens as shown in Table 2.

Procedure A, which is a three point bending test was adapted to test the specimens. All specimens were loaded at a rate of crosshead movement of 1.0 mm/min until failure.

Load versus crosshead displacement data throughout the test method, maximum load, final load, and load at any obvious discontinuities in load-displacement data were recorded at a rate of 20 Hz.

Test Results

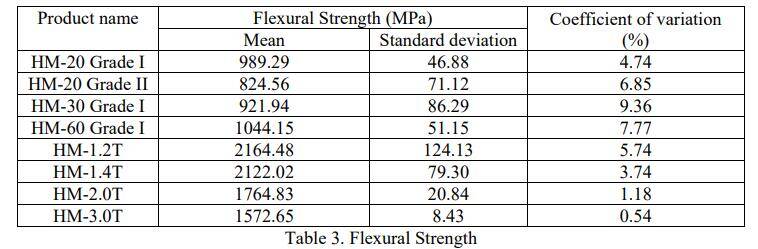

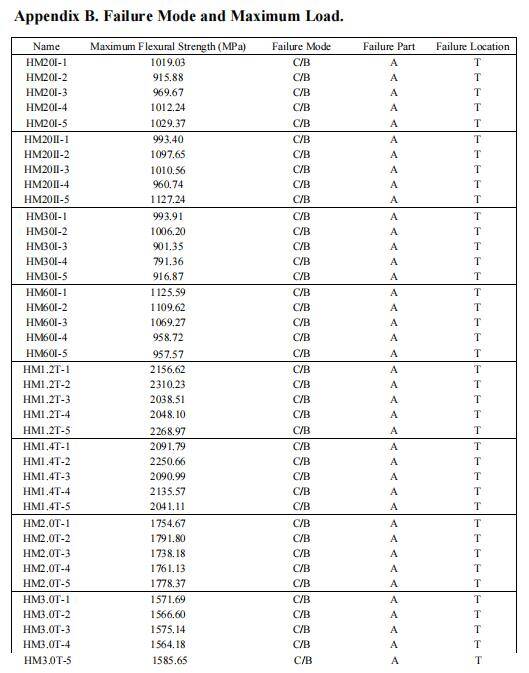

Failure mode and Maximum flexural stress for each specimen are summarized in Appendix B.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

HM-1.4TT is a high strength, high modulus unidirectional carbon fiber reinforce polymer(CFRP) laminate for structural strengthening