Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

How Many Layers of Carbon Fiber for Structural Reinforcement?

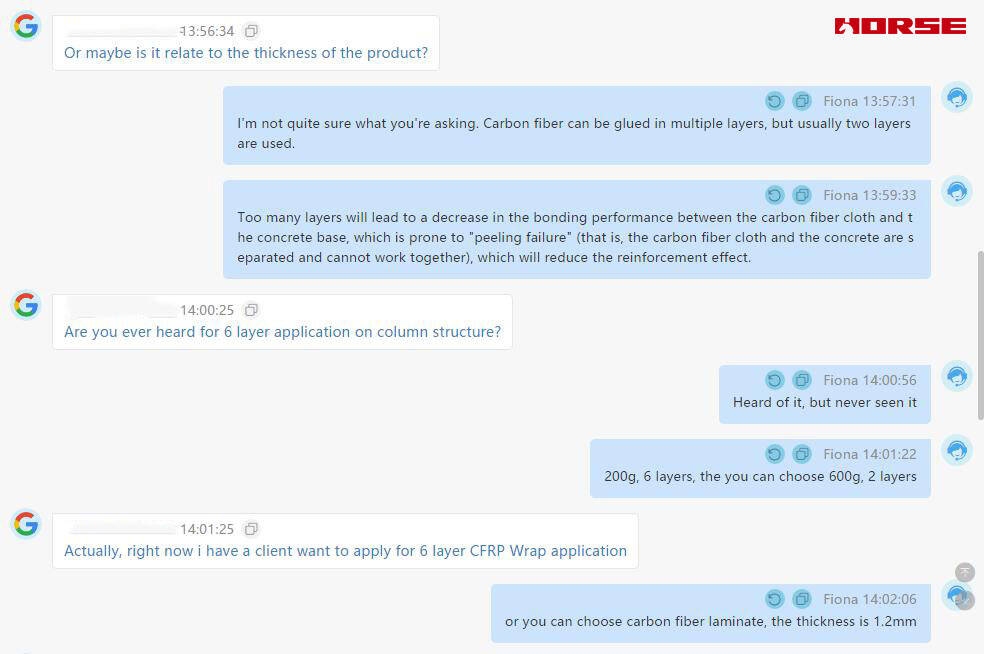

This afternoon, I received a question from an Indonesian customer. He asked if six layers of carbon fiber reinforced columns could be applied.

Because of privacy concerns, the client's company and name are censored.

Whether 6 layers can be applied in carbon fiber reinforcement needs to be comprehensively judged in combination with specification requirements, structural stress conditions and construction feasibility. It is usually not recommended to directly apply 6 layers.

WHY?

Clear Restrictions at the Regulatory Level

Chinese and Japanese standards clearly limit the number of carbon fiber sheeting layers: For reinforcement in tension zones, the number of unidirectional carbon fiber sheeting layers is typically limited to four. If additional layers are required in special circumstances, a specific design demonstration is required, and supporting measures (such as layered anchoring and controlled interfacial bonding) must be implemented.

The core reason for these regulatory restrictions is that excessive layers can weaken the bond between the carbon fiber sheet and the concrete base, making it prone to "stripping failure" (where the carbon fiber sheet separates from the concrete and becomes incompatible), reducing the reinforcement effectiveness and even posing safety risks.

Constraints on Construction Feasibility

When applying multiple layers, each layer must be evenly coated with adhesive, free of bubbles and hollows. Six-layer application is extremely challenging: adhesive can easily accumulate or become lost between layers, creating weak links. Furthermore, the flatness of the carbon fiber sheeting is difficult to control, and wrinkles may form between layers, further weakening the bond strength.

Furthermore, applying multiple layers increases the weight of the structure (although the carbon fiber sheeting itself is lightweight, the accumulated weight of the adhesive is not negligible) and may affect the appearance of the structure and subsequent decorative work.

Problems with Stress Coordination

Carbon fiber cloth offers the advantage of high tensile strength, but it must work in concert with concrete to withstand stress. When there are too many layers, the stress transfer path in the outer carbon fiber cloth becomes longer, which can lead to "stress hysteresis" (the outer fibers cannot fully exert their tensile properties). This results in material waste and can cause localized damage due to uneven stress distribution.

So, what is the recommended number of layers of glue?

Conventional: 1-4 layers

1-2 layers: Suitable for minor load-bearing capacity deficiencies, crack repairs, or stiffness enhancement (such as local reinforcement of floor slabs and beams). This is the most commonly used number of layers due to its ease of construction and high bond reliability.

3-4 layers: Suitable for moderate load-bearing capacity deficiencies. Construction quality (e.g., base preparation, adhesive coating thickness, compaction process, etc.) must be strictly controlled according to specifications. Additional anchoring measures (e.g., carbon fiber battens, mechanical anchor bolts) should be implemented if necessary to prevent delamination.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

High strength unidirectional carbon fiber fabric for concrete repair and structural strengthening