Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Carbon Fiber CFRP Strengthening Process Steps

01

Construction preparation

Based on the actual condition of the construction site and reinforced concrete components, compare them with the design drawings to determine the construction plan and construction plan, and prepare well before construction.

Materials and main machinery

Main materials: carbon fiber sheet, carbon fiber adhesive, carbon fiber base adhesive, repair and leveling adhesive, etc

Main equipment: angle grinder, mixer, electronic scale, scraper, drum, etc

Working conditions

Construction should be carried out under ambient temperature conditions above 5 ℃. If the ambient temperature is below 5 ℃, special adhesives suitable for low temperature should be used or other heating treatment measures should be taken. If the temperature is below 0 ℃, construction should be suspended.

Positioning and laying out

Carry out laying out operations within the construction scope according to the design drawings.

02

Grassroots treatment

The grassroots treatment directly determines the quality of carbon fiber sheet adhesion.

Surface treatment

Remove the concrete paint layer, oil stains, and dirt, expose the surface of the concrete, and use an angle grinder to grind off the 1-2mm thick surface layer until the new surface of the concrete structure is completely exposed. The areas on the surface of concrete that exhibit deterioration such as peeling, honeycombing, and corrosion should be chiseled out.

The polishing of the components should be smooth, especially the protruding parts on the surface, and the corners of the concrete components should be trimmed into rounded corners using an angle grinder. If the radius of the circular arc angle is not specified in the design, for beams, slabs, and columns, a circular arc with r ≥ 20mm should be taken.

Polish and flatten the uneven areas on the surface, and use oil-free compressed air to blow away dust, keeping the surface clean and dry.

Crack treatment

After cleaning and surface chiseling or cleaning, if local defects and cracks are found in the bonding area, the cracks should be grouted or sealed according to the design requirements.

03

Prepare adhesive

Accurate proportioning is necessary to ensure the normal curing of carbon fiber adhesive.

Weighing and dispensing

Weigh the raw materials accurately using a balance according to different mix proportions, and prepare the bottom coating adhesive, leveling adhesive, and bonding adhesive separately. Prepare a container, place the main ingredient of adhesive (i.e. component A) and the curing agent (i.e. component B) into the container, and use a low-speed mixer to stir thoroughly and evenly until there are no bubbles generated, then it can be used.

Glue dosage

The appropriate amount of carbon fiber adhesive for each configuration is 1-2kg; The appropriate amount of repair and leveling adhesive for each configuration is 0.5-1Kg; The optimal amount for each configuration of carbon fiber adhesive (carbon fiber impregnation adhesive) is 1-2kg.

All adhesive materials are required to be completed within 1 hour of construction.

04

Apply primer

Greatly enhance the stress transfer between carbon fiber and concrete.

Primer glue roller coating

When applying base adhesive, construction should be carried out according to regulations, and the application should be uniform and full. The application range of base adhesive should exceed the surrounding area of carbon fiber material adhesion by 20-30mm.

Evenly apply or brush with a roller or short bristle brush on the polished surface of the structure, with a adhesive layer thickness not exceeding 0.4mm, and without missing or flowing bubbles. Let it stand for 5-7 hours until no hands touch it before proceeding to the next process. The curing time depends on the on-site temperature, and it is advisable to have a dry touch with your fingers, generally not less than 2 hours.

Precautions

The mixing amount of the base adhesive should not be too much each time, and it should be mixed as needed. Expired epoxy resins should not be used, and mixing equipment should be clean and tidy. The rollers that have been soaked in solvent should not be used.

Place the main agent and curing agent in a container in a certain proportion, stir evenly with a stirrer, determine the dosage based on the actual temperature on site, and strictly control the usage time.

The carbon fiber sheet should be pasted immediately after the bottom adhesive fingers dry.

05

Repair and leveling

Make the carbon fiber stick without hollowing, and the force is more uniform.

Repair and leveling

After the primer gel, if the concrete bonding surface is sunken, use repair glue to repair and level it. For larger areas of poor quality layers, polymer cement mortar can be used for repair after chiseling; Parts with height differences such as template joints should be filled with flat repair materials.

For areas with height differences, misalignment, and internal corners, they should be polished or smoothed to a smooth surface, and then the pasted surface should be polished and roughened to minimize the height difference.

The leveling adhesive material must be cured and then polished and roughened. The curing time depends on the temperature on site, and it is advisable to dry the finger touch. Generally, it should not be less than 2 hours before proceeding to the next process.

Quality control

Use a scraper to fill and level the concave areas on the concrete surface with adhesive, and there should be no sharp edges. The height difference between the repair surface and the concrete surface should not exceed 1mm.

The corners are repaired with leveling adhesive to create smooth arcs with a radius of no less than 20mm. The surface flatness deviation without special requirements should not exceed 2mm/m.

Precautions

The smoothness of the concrete bonding surface is qualified. After the polishing process is completed, wipe it clean with a white sheet or cotton yarn dipped in industrial acetone. Then proceed to the next process immediately and should not be left for a long time to prevent water, oil, and dust from sticking to the adhesive surface.

06

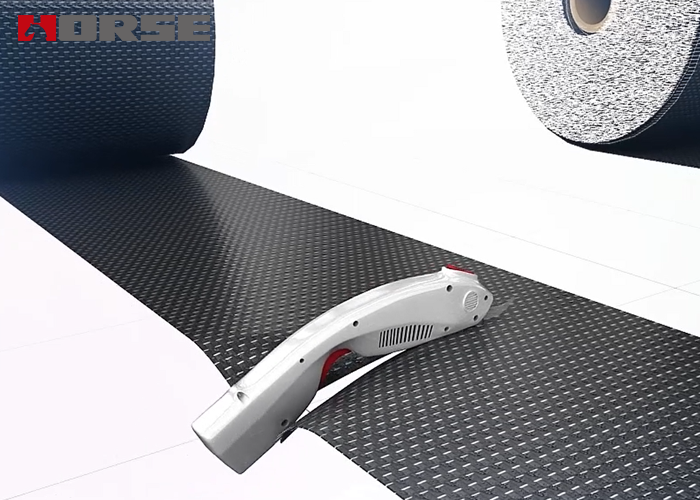

Cutting carbon fiber sheet

Accurate cutting can to some extent avoid carbon fiber damage.

Sheet cutting

Cutting carbon fiber sheet can be done with special scissors or with sharp art knives to the desired size.

Quality control

The cutting of carbon fiber sheet should be carried out on a clean site or room workbench.

The cut carbon fiber sheet should not be folded and should not be contaminated with dust and oil.

07

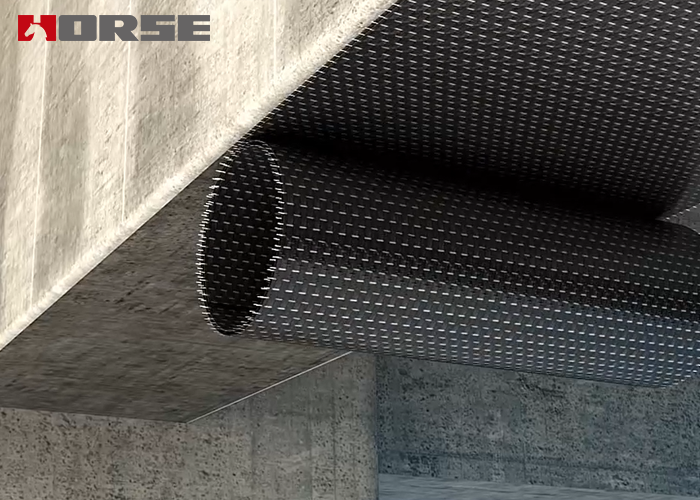

Paste carbon sheet

Carbon fiber sheet reinforcement core link.

Paste carbon fiber sheet

Apply the prepared carbon fiber adhesive/carbon fiber impregnation adhesive evenly to the concrete surface of the bonding area.

Apply the cut carbon fiber sheet (fabric) to the surface of the concrete coated with carbon fiber adhesive according to the laying position; Carbon fiber sheet/fabric should be fully flattened without wrinkles.

Along the fiber side, use a specially designed drum to perform multiple unidirectional rolling on the pasted fiber surface. The carbon fiber impregnated resin should be fully impregnated into the carbon fiber fabric, and the layer of the carbon fiber fabric should be evenly compacted without any bubbles.

When pasting carbon fiber sheet in multiple layers, repeat the above steps layer by layer.

Quality control

When pasting multiple layers, when the surface of the upper layer of carbon fiber sheet reaches a dry touch, immediately paste the next layer. If the drying time exceeds 60 minutes, wait for 12 hours before continuing with pasting. After 12 hours of pasting, the dust on the bonding surface of the carbon fiber sheet should be wiped clean again before pasting.

The overlap length of carbon fiber sheet along the direction of fiber stress should not be less than 100mm. When using multiple or multiple layers of carbon fiber sheet for reinforcement, the overlapping positions of each strip or layer of carbon fiber sheet should be staggered from each other. The staggered distance should not be less than 250mm and not less than 1.5 times.

The surface of the last layer of fiber fabric should be evenly coated with impregnation/carbon fiber adhesive. To ensure the bonding quality of the material behind the carbon fiber sheet, fine quartz sand can be immediately sprinkled on its surface after applying carbon fiber adhesive/impregnation adhesive.

08

Maintenance and protection

Carbon fiber sheet reinforcement core link.

Curing

Within 24 hours after the completion of construction, it is necessary to prevent rain or moisture, and pay attention to protection to prevent hard objects from damaging the construction surface.

When the average temperature is 20-25 ℃, the curing time shall not be less than 3 days; When the average temperature is 10 ℃, the curing time shall not be less than 7 days.

Repair protection

In cases where the reinforcement area is susceptible to external impact, it is necessary to apply cement mortar with a protective thickness of no less than 20mm and a mortar grade of no less than M10, or depending on the design of the thickness of the sprayed protection.

When the reinforcement area is not affected by external forces, painting can also be used for waterproofing and anti-corrosion treatment.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

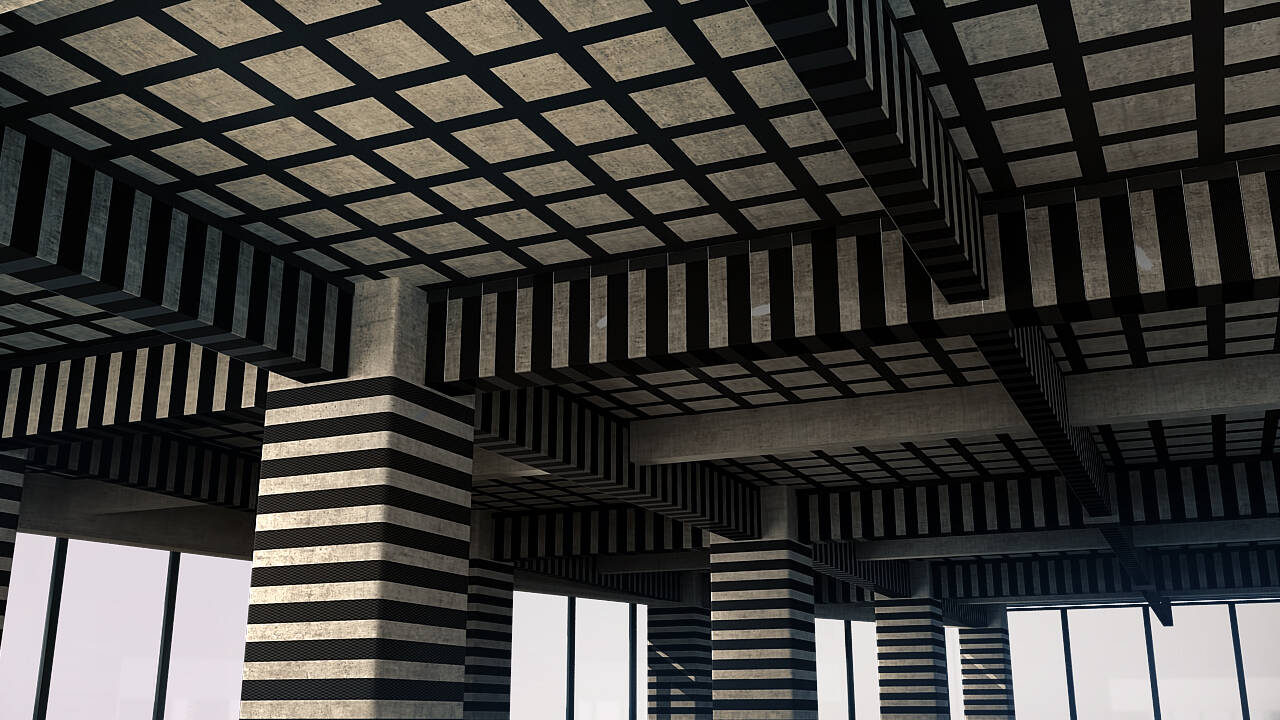

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

Good impregnation carbon fiber adhesive for applying carbon fiber reinforced polymer(CFRP) wrap for structural strengthening

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.