Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

How Can Epoxy Structural Adhesive Be Effectively Applied At High Temperatures?

Factors affecting summer construction

In this "barbecue+steamer" mode, the temperature and humidity are in a dual high state for a long time.

Epoxy adhesive is a temperature sensitive material, and its product properties and curing time will show significant differences due to different temperatures. When the ambient temperature increases, the viscosity of the structural adhesive decreases and the curing time shortens, which is a significant characteristic of epoxy resin itself.

In addition, humidity can affect the mechanical properties of epoxy adhesives. During the curing process of adhesives, if the humidity is high, water can penetrate into the polymer body and have two types of interactions with the polymer body: water molecules can break the hydrogen bonds and other secondary bonds between polymer molecules, causing the polymer to undergo plasticization and causing a decrease in mechanical strength and other physical properties.

Construction process and key points of summer structural adhesive

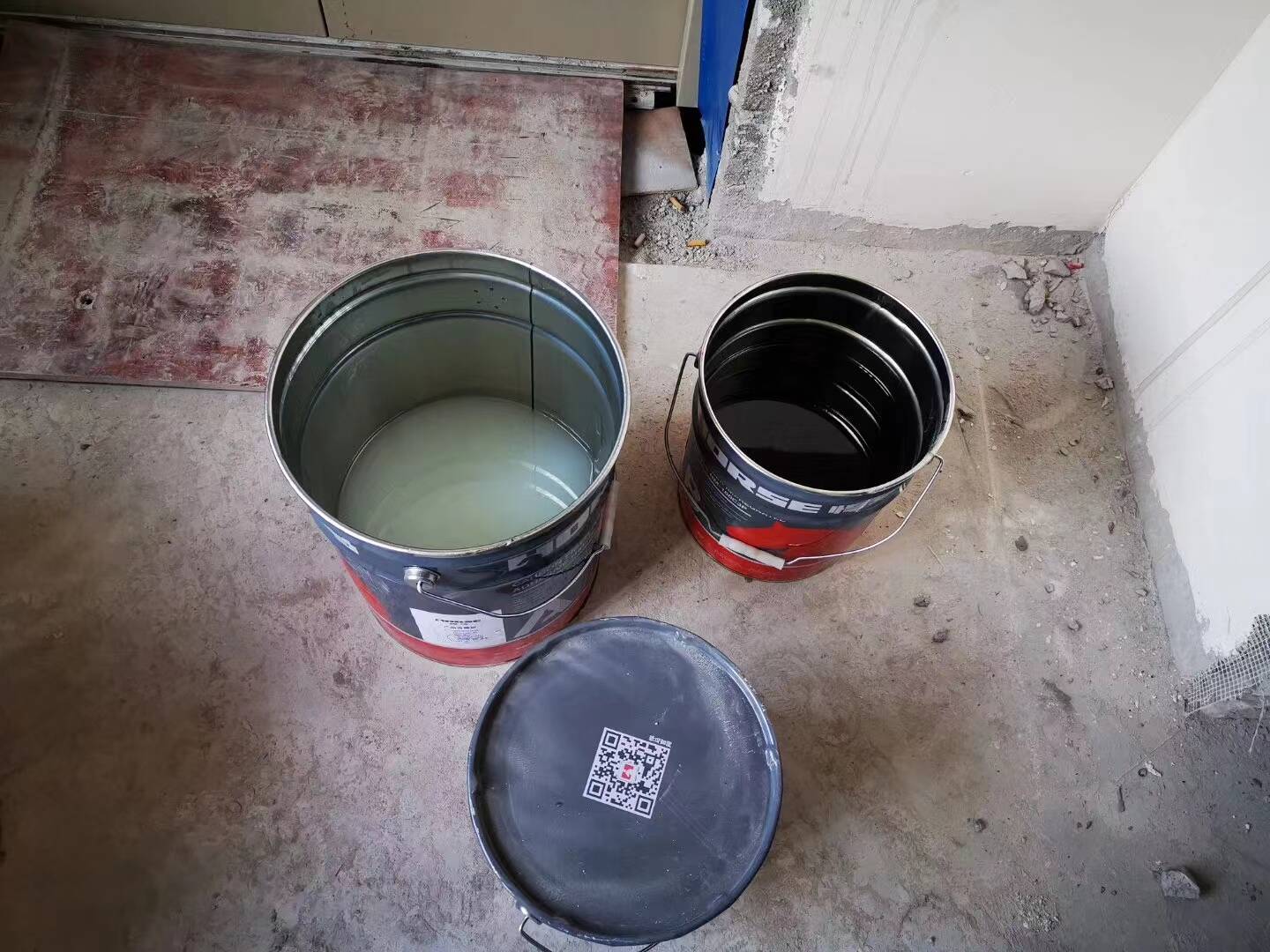

The following will explain the process and key points of summer structural adhesive construction using impregnated adhesive (liquid) and carbon plate adhesive (paste) as examples.

Process and Key Points of Impregnated Adhesive Construction

1. Positioning and setting out: Determine the position of pasting carbon fiber cloth according to the drawing, and mark the setting out.

2. Surface treatment: Clean the concrete defects on the surface of the reinforced components, expose the concrete structural layer, and repair it flat. The surface should be cleaned and kept dry. The moisture content of the concrete surface layer where the fiber material is pasted should not exceed 4% and should not exceed 6%; If the humidity is too high in summer, manual drying should be carried out.

3. Preparation of adhesive: Before preparation, mix components A and B evenly, weigh the ratio strictly according to the ratio, and stir thoroughly until there is no color difference. Due to the high temperature and fast curing time in summer, the amount of glue added should not be too large. It is advisable to have sufficient operational time for the gel at the summer construction temperature.

4. Brush the bottom layer of impregnating adhesive: Apply the impregnating adhesive evenly to the bonding area. In summer, the structural adhesive has a relatively low viscosity and can be applied in small quantities multiple times.

5. Pasting carbon fiber cloth: Lightly press the cut carbon fiber cloth onto the position to be pasted, and use a dedicated roller to roll it multiple times along the fiber direction to squeeze out bubbles, so that the adhesive solution is fully soaked in the carbon fiber cloth. In summer, the curing time of structural adhesive is shortened, and attention should be paid to pasting carbon fiber cloth before the structural adhesive fingers dry.

6. Apply surface layer impregnation adhesive: Apply impregnation adhesive evenly on the surface of carbon fiber cloth.

7. Surface protection: Treat according to relevant standards to ensure reliable bonding between protective materials and fiber sheets.

Carbon plate adhesive construction process and key points

1. Positioning and setting out: Determine the position of pasting carbon fiber plate according to the drawing, and mark the setting out.

2. Surface treatment: Clean the concrete defects on the surface of the reinforced components, expose the concrete structural layer, and repair it flat. The surface should be cleaned and kept dry. The moisture content of the concrete surface layer where the fiber material is pasted should not exceed 4% and should not exceed 6%; If the humidity is too high in summer, manual drying should be carried out.

3. Cutting of carbon plate: according to the length of the design drawing, the Angle grinder is used to cut the carbon plate.

4. Wipe the carbon plate: Use acetone or ethanol to wipe the surface of the carbon plate until there is no dust. Due to high temperatures in summer, cleaning solvents are prone to volatilization, and attention should be paid to the impact on cleaning effectiveness.

5. Preparation of adhesive: Before preparation, mix components A and B evenly, weigh the ratio strictly according to the ratio, and stir thoroughly until there is no color difference. In summer, due to the high temperature and fast curing time, the amount of adhesive should not be too much. It is advisable to have sufficient operational time for the gel at this construction temperature.

6. Applying carbon plate adhesive: The wiped clean carbon fiber plate should be immediately coated with structural adhesive. The adhesive layer is inverted conical, with a middle thickness of 1.5-2.0mm and thin on both sides, with an average thickness of 1.5-2.0mm.

7. Pasting carbon fiber plate: Lightly press the carbon fiber plate coated with carbon plate adhesive onto the position where it needs to be pasted, and use a dedicated roller to evenly and smoothly compact along the fiber direction, so that the adhesive is squeezed out from both sides, ensuring compactness and no voids. Scrape off excess colloid from the edge of the carbon plate, forming a 45 ° inclination angle.

8. Temporary support of carbon fiber plate: to avoid detachment due to gravity and insufficient strength of the carbon plate adhesive in the early stage.

9. Surface protection: Treat according to relevant standards to ensure reliable bonding between protective materials and fiber sheets.

Common problems during summer construction

Sagging phenomenon

Reason: As the temperature increases, the epoxy resin adhesive will become thinner, especially paste adhesives such as steel adhesive, reinforcement adhesive, and carbon plate adhesive, which show the most obvious performance. Structural adhesive sagging not only causes waste, but also leads to poor construction experience for workers during operation, reducing labor efficiency and prolonging the construction period. In more severe cases, it can even lead to incomplete contact between reinforcement components and materials, leaving safety hazards for the structure.

Solution: choose structural adhesive with stable performance and good Thixotropy to avoid colloid falling and inconvenient construction

Explosion phenomenon occurs during mixing of epoxy structural adhesive

Cause: The reaction of component A (epoxy) and component B (curing agent) is a Exothermic reaction. There is a large amount of mixture of component AB, and the heat cannot be diffused in a short time, which will lead to explosive polymerization and smoke. In this case, the operation time will be extremely short, and especially rapid solidification is not conducive to firm bonding.

Solution: AB components should be mixed strictly in proportion (mass ratio), with minimal and frequent mixing as much as possible to avoid excessive mixing and short gel curing time, resulting in waste.

After pasting the carbon cloth, the surface is impregnated with adhesive and undergoes color changes

Reason: The main components of epoxy structural adhesive are component A (epoxy) and component B (amine curing agent). Tertiary amine accelerators in curing agents can quickly turn yellow or red under heat, sunlight, or UV light, leading to discoloration of the structural adhesive.

Solution: After extensive testing, the discoloration of the impregnated adhesive has no effect on the adhesive performance.

After pasting the carbon cloth, cylindrical colloids appear on the surface

Reason: Excessive brushing of structural adhesive resulted in uneven cylindrical colloids on the surface of the adhesive.

Solution: Grind off the cylindrical colloid, and do not apply too much or too little impregnation glue when applying it on the roller. The recommended amount of adhesive per square meter for Kaben impregnation glue is 0.6-0.8kg.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Good impregnation carbon fiber adhesive for applying carbon fiber reinforced polymer(CFRP) wrap for structural strengthening

High strength carbon fiber reinforced polymer plate adhesive for applying CFRP laminate/strip/plate on the structural members

Two-component modified epoxy resin adhesive, applied to chemical planting reinforcing bar and anchor bolt anchoring