Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Analysis Of Reinforcement Methods For Cantilever Beams

Cantilevered structure is one of the common structural forms in engineering structure, such as awning, canopy, external balcony, cantilever, etc. in construction engineering. This kind of structure is a cantilevered structure by cantilevering beams or slabs from the main structure. Taking into account the particularity of the force of the cantilever beam in the entire structural system, once the cantilever beam appears cracks and deformation due to the design, construction quality and use environment, it will constitute a greater safety hazard.

01 Problems in design

1.The problem of load value

According to GB50009-2012 "Building Structure Load Code", the standard value of live load is 2.5-3.5kN/m², if 1.5kN/m² is taken, it will cause design safety hazards.

2. Mistakes in design calculations

In the anti-overturning check calculation of reinforced concrete cantilever beams in masonry structure, the distance between the overturning point of the cantilever beam and the outer edge of the wall should be calculated in accordance with the requirements of the "Code for Design of Masonry Structures":

3. Mistakes in shearing design

The code stipulates that when the length of the cantilever beam is greater than 1.5m, a row of bent steel bars must be installed for shear resistance. If there is a concentrated load at the beam end, two rows of bent steel bars must be installed. In reality, the beam end is often equipped with an equivalent concentrated load of 240mm thick masonry wall at the beam end due to the needs of users, but this problem may be ignored in the design, resulting in quality accidents.

Many problems with lifting beams in engineering are due to insufficient shear force, and the reasonable configuration of stirrups and bent steel bars is the key to whether they can meet the requirements.

02 Problems in construction

There are two main aspects of construction issues:

1. Improper rebar configuration

Because it is easy for on-site workers to trample down the negative reinforcement of the cantilever beam during operation, the effective height h0 of the beam slab calculated and controlled by the section is reduced. In addition, there are situations where the rebar positions are reversed, which is even more dangerous and may collapse when the mold is removed.

2. Insufficient concrete strength and size

This situation is also a problem that easily occurs in engineering. Insufficient strength means that the area of the compression zone increases and the tension main reinforcement h0 decreases, and the tension stress of the main reinforcement increases. After the mold is removed, there will be greater deformation and cracks, which will cause hidden dangers.

3. Other reasons

Less or mismatched reinforcement during construction, improper or incorrect use of materials (such as using light circle instead of rebar), low-quality cement, and random application of other concrete mix ratios without design verification will all affect the quality of the components.

03 How to deal with quality problems

For cantilever beams with quality problems, there are many ways to strengthen them. The following is a discussion and analysis of several effective methods in engineering.

1. Bonded steel reinforcement

The steel bonding method uses epoxy resin glue to reinforce the original cantilever beams in vitro, that is, external bonding steel reinforcement. This method is a relatively mature technology, characterized by strong pertinence, simple on-site construction, little damage and disturbance to the original structure, and almost no increase in the volume of the original structure.

The disadvantage is the stress hysteresis of the pasted steel plate. Since the cantilever beam reinforcement is generally carried out without unloading, the steel bars in the original beam have a certain stress, and the pasted steel plate will only produce stress under the action of post-loading.

2. Carbon fiber reinforcement

Carbon fiber cloth has high tensile strength and fatigue strength along the fiber direction, and is suitable for strengthening the tensile area of structural members. Paste carbon fiber cloth on the tension area of the cantilever beam for bending reinforcement, and add lateral bead at the cantilever beam support. Outside the reinforced area, leave enough anchorage length at both ends.

Carbon fiber reinforcement is also a relatively mature technology. Carbon fiber reinforcement is similar to outer profile steel. It is easier to construct than outer profile steel, has a shorter construction period, has better corrosion resistance and aging resistance, and does not damage the original structure.

3. Increase section method

When the load-bearing capacity of the cantilever beam differs greatly, and the rigidity does not meet the requirements, it is more effective to use the method of enlarging the cross-section of the outer concrete to strengthen. In the reinforcement design, three-sided thickening, two-sided thickening or single-sided thickening can be selected according to the force-bearing properties, structural characteristics and site conditions of the original components.

The added concrete is in the tension zone, and it has the effect of bonding and protecting the added steel. When the added concrete is in the compression zone, the effective height of the component is increased, thereby improving the flexural and shear bearing capacity of the component, increasing the rigidity of the component, and the reinforcement effect is obvious.

Compared with the general method, the concrete enlarged section method is easy to guarantee the construction quality. Before refilling the concrete, the base of the original cantilever beam should be chipped and cleaned. Then apply a polymer interface agent on the surface of the tick chisel to make the new and old concrete surfaces bond well and solve the problem of shear force transmission between the old and the new interface.

Note: Since the reinforcement member is actually a superimposed member, it is mainly manifested in the lagging of concrete strain and the leading of steel bar stress. Therefore, in the design, the design value of the strength of the supplementary steel bar should be multiplied by a certain reduction factor.

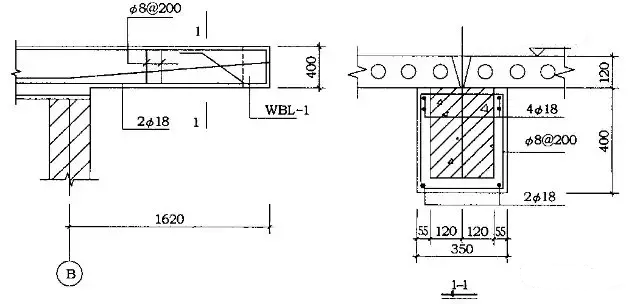

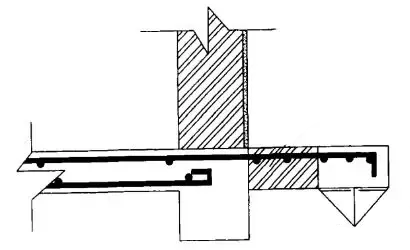

4. Excavation and reinforcement method

If the root of the cantilever does not meet the requirements but the reinforcement is sufficient, the thickness of the root of the suspension can be increased by the method of excavation and reinforcement. When reinforcing this type of component, first use scaffolding or supports to securely fix the bottom of the cantilever beam to be reinforced, and be able to bear the weight of the structure and the construction load without sinking.

As shown in the picture, first use a steel drill to knock off the concrete at the root of the suspended slab, then dig out the bottom surface of the concrete and re-tilt the formwork. Clean the concrete joints, brush with plain cement slurry and supplement with fine stone concrete not less than C25 to thicken the cantilever roots of the newly poured concrete and pay attention to maintenance. This method can completely solve the problem of cracks and deformation of the epithelium of the cantilever root.

04 Summary

In engineering testing, the reinforced structure begins to bear the force after the original structure's bearing capacity reaches a certain level. At the same time, the above-mentioned reinforcement method reinforces the overhanging member, which is a secondary stress state. It is not a simple superposition of the new and old structures, and the distribution of the stress is not uniform. Therefore, simple superposition calculations cannot be performed.

In order to make the reinforced components safer, the safety factor of the design should be appropriately increased to achieve the most ideal and economical reinforcement effect, and the construction shall be carried out in strict accordance with the standards to ensure that the design requirements are met.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

two-components modified epoxy resin adhesive, with high quality plastic tube, double cartridge package